Stuck or sluggish fermentations often occur in winemaking. They are the most serious fermentation problems of the wine industry. In stuck or sluggish fermentations, the available sugar is not completely used by the yeast, and fermentable sugar remains at the end of these fermentations.

There are many reasons of stuck or sluggish fermentations, such as deficiency of yeast assimilable nitrogen, lack of survival factors (long-chain unsaturated fatty acids, sterols), inhibition of enthanol and toxic medium-chain fatty acids (hexanoic, octanoic and decanoic acids).

Yeast cell wall (also called yeast hulls or yeast ghosts) is the remainding of yeast extract process (incluses yeast cell wall and membrane complex). It represents 18-30% of the yeast dry weight. Yeast cell wall is made of 30-60% polysaccharides, 15-30% proteins, 5-20% lipids and a small amount of chitin.

During wine fermentation, yeast cell wall adsorbs harmful compounds (octanoic, decanoic acid and ochratoxin A) and provides growth and survival factors (sterols, unsaturated fatty acids). Yeast cell wall have been stuggested as a nutrient to alcoholic fermentation to prevent stuck or sluggish fermentations. The effects of the yeast cell wall are due to the adsorption of toxic medium-chain fatty acids of fermentation byproducts and the supply of survival factors.

During wine fermentation, these fatty acids inhibit yeast growth and affect yeast activity. Yeast cell wall has the capacity to adsorb medium chain fatty acids (Lafon-Lafourcade et al.1984). The adsorption capacity of the medium-chain fatty acids can reduce their inhibition to yeast growth, help the yeast to optimize the fermentation performance and avoid stuck or sluggish fermentations.

Nov 19, 2018

By Fangfang

Stuck or sluggish fermentations often occur in winemaking. They are the most serious fermentation problems in the wine industry. In stuck or sluggish fermentations, the available sugar is not entirely used by the yeast, and fermentable sugar remains at the end of these fermentations.

There are many reasons of stuck or sluggish fermentations, such as deficiency of yeast assimilable nitrogen, lack of survival factors (long-chain unsaturated fatty acids, sterols), inhibition of ethanol and toxic medium-chain fatty acids (hexanoic, octanoic and decanoic acids).

Yeast cell wall (also called yeast hulls or yeast ghosts) is the remaining of yeast extract process (includes yeast cell wall and membrane complex). It represents 18-30% of the yeast dry weight. Yeast cell wall is made of 30-60% polysaccharides, 15-30% proteins, 5-20% lipids and a small amount of chitin.

During wine fermentation, yeast cell wall adsorbs harmful compounds (octanoic, decanoic acid and ochratoxin A) and provides growth and survival factors (sterols, unsaturated fatty acids). Yeast cell wall has been suggested as a nutrient to alcoholic fermentation to prevent stuck or sluggish fermentations. The effects of the yeast cell wall are due to the adsorption of toxic medium-chain fatty acids of fermentation byproducts and the supply of survival factors.

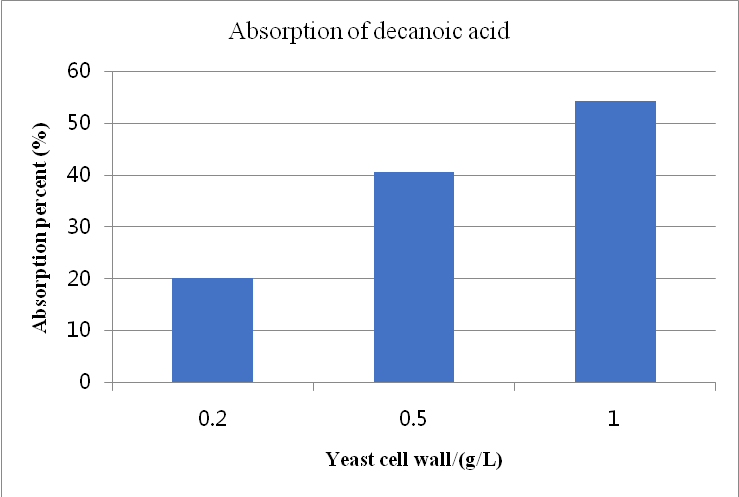

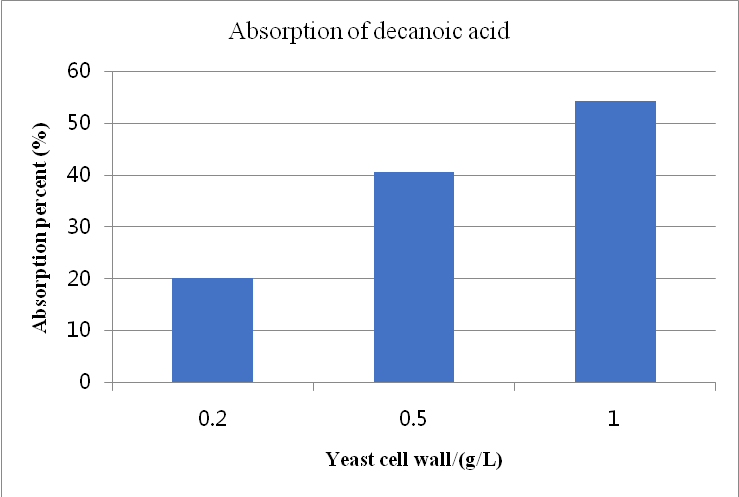

During wine fermentation, these fatty acids inhibit yeast growth and affect yeast activity. Yeast cell wall can adsorb medium chain fatty acids (Lafon-Lafourcade et al.1984). The adsorption capacity of the medium-chain fatty acids can reduce their inhibition to yeast growth, help the yeast to optimize the fermentation performance and avoid stuck or sluggish fermentations.

Fig 1 Adsorption of decanoic acid by yeast cell wall in synthetic medium (Lafon-Lafourcade et al.1984)

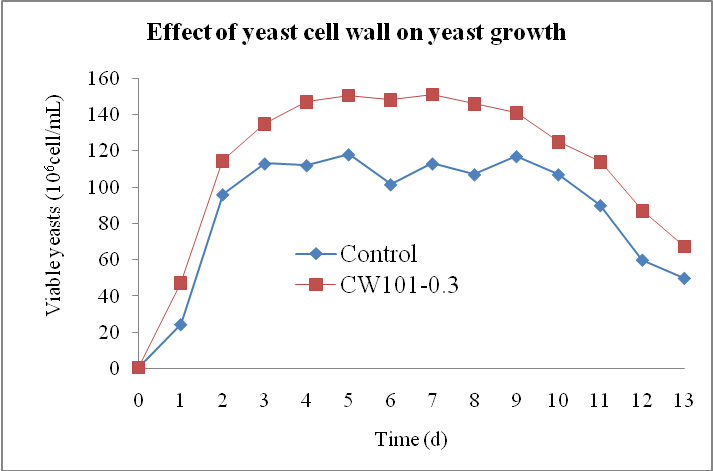

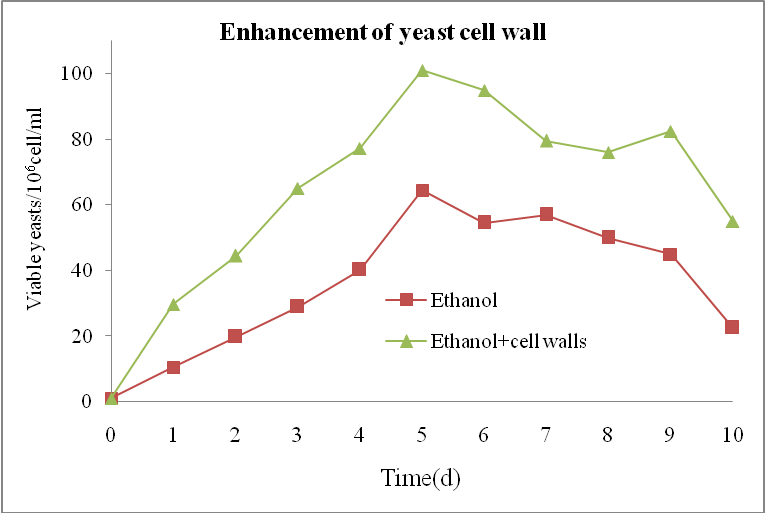

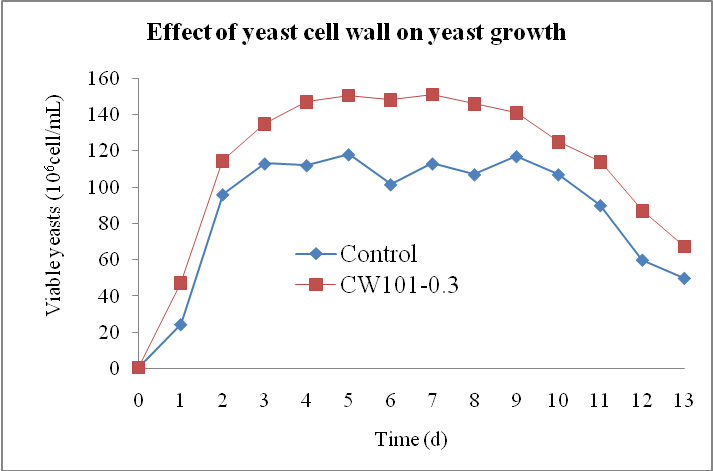

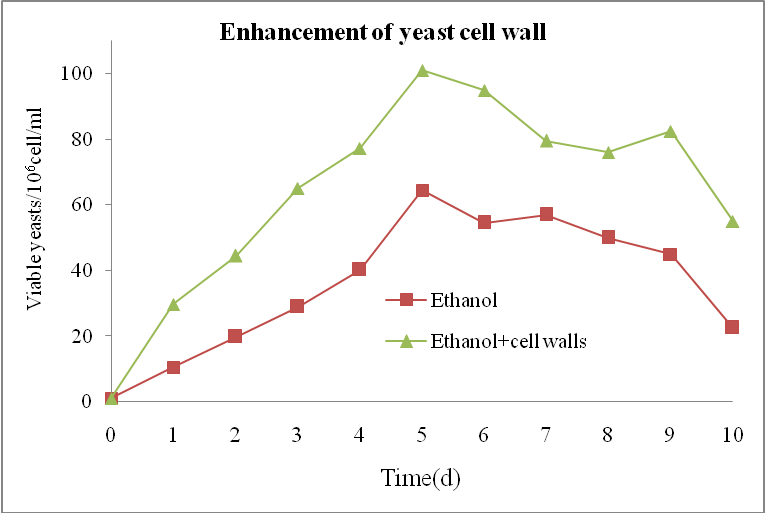

Yeast cell wall products are rich in survival factors (sterols, unsaturated fatty acids). It is important to increase yeast growth to overcome stuck or sluggish fermentations. Yeast cell wall provides survival factors, increase cell viability and vitality and promotes alcoholic fermentation. The effect of ethanol toxicity on yeasts is well known. Yeast cell wall products have been used to lower this toxicityandpromote fermentation and prevent stuck fermentations.During the decline phase of yeast growth, adding yeast cell wall to fermentations will enhance yeast growth and viability by the sterols and unsaturated fatty acids.

Fig 2. Cell viability in 24 °Brix fermentations inoculated at 1 x 106 cells/ml.

CW101-0.3:0.3 g/l yeast cell wall CW101;Control: no yeast cell wall.

Fig 3 Cell viability in alcohol-adjusted must fermentations inoculated at 1 x 106 cells/ml.

Ethanol:contained 7%v/v ethanol and 11.4°Brix sugar;

Ethanol+cell walls:contained 7%v/v ethanol, 1g/l yeast cell wall CW101 and 11.4°Brix sugar

Angel yeast has two yeast cell wall products. CW101 is a traditional yeast cell wall. CW201 is a kind of upgrade product, has higher dissolution rate and yeast polysaccharides.

About Angel Distilled spirits and Biofuels:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

| Published by Fang Fang

Senior R & D Engineer

Angel Distilled spirits and Biofuels Division |

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86 717 6353619

Email: ethanol@angelyeast.com