-

Home > News & Events > Blog > Enzymes

27th, April

By Sun Meng

Enzyme plays the most important and key role in the production of savoury flavor. Angel's complex enzyme MF101 and FF104 can break down meat quickly with less bitter taste hydrolysate, enhance the flavor and retain the characteristic flavor.

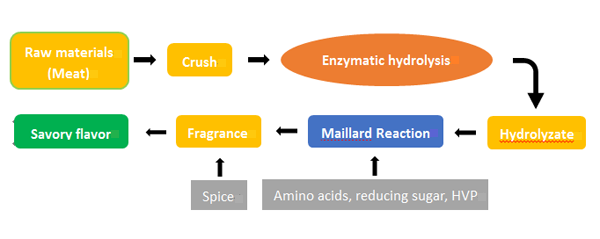

With the vigorous development of food industry, the demand for savoury flavor widely used in instant noodle flavoring, chicken essence, canned, bacon food, animal feed and pet food is gradually increasing. The savoury flavor is a mixture of two or more of aroma components such as thermo responsive flavoring, food flavoring compound, spice (or extract) and edible carrier and/or other food additives. Its production is mainly compounded which uses amino-containing substance ( such as HAP, HVP, amino acids and yeast extract, etc.) and reducing sugar containing carbonyl, fat, VB1 and other substances after Maillard Reaction, then adding natural (or natural equivalent) fragrance monomer. The main production process of savoury flavor shows below:

Among the above processing, enzyme plays the most important and key role in the production of savoury flavor. As we all know, meat protein decomposes into amino acid and oligo-peptide under the function of enzymes, which significantly increases concentration of meat flavor precursor. Meat enzymatic hydrolysate contains lipid that shows the characteristic of meat flavor, making meat tasted richer.

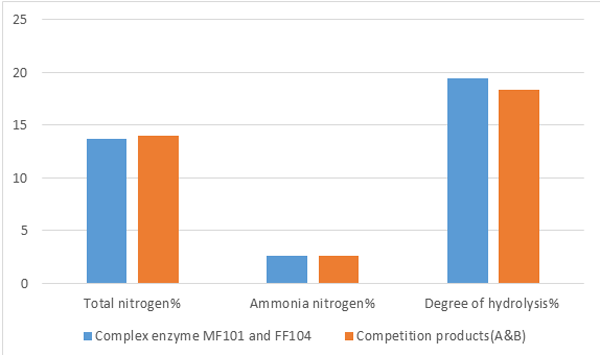

We use AnnzymeTM (complex enzyme MF101 & FF104) and competition products (A & B) to hydrolyze chicken respectively with the same dosage of enzymes for 2-3h. The experimental results show as follow:

Degree of hydrolysis of chicken enzymatic solution with AnnzymeTM (complex enzyme MF101 & FF104) was 1% higher than that with competition product (A&B). Compared with competition products, complex enzyme MF101 and FF104 hydrolyze chicken provide more amino acids and small peptides for the subsequent thermal reaction. By HPLC, the umami characteristic of AnnzymeTM (complex enzyme MF101 and FF104) is significantly better than that of competition products (A&B). The existing enzyme preparation (complex enzyme MF101 and FF104) can break down meat quickly with less bitter taste hydrolysate, enhance the flavor and retain the characteristic flavor. The complex enzyme MF101 and FF104 are effective products for the savoury flavor production.

About AnnzymeTM:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

About Angel :

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86-717-6369520, 6369558

Fax: +86-717-6370680

email: aie@angelyeast.com