-

Home > News & Events > Blog > Enzymes

October 24

By Zophi Jin

In the modern food industry, protein hydrolysis is generally based on enzymatic hydrolysis. Protein hydrolysate has better physiological activity than intact protein, and small molecule peptides are easily and efficiently absorbed by the human body [1]. Recent studies have shown that hydrolysates such as soy peptides also have health functions such as low antigenicity, blood pressure lowering, and cholesterol inhibition. However, proteins produce varying degrees of bitterness during enzymatic hydrolysis, limiting the application of protein hydrolysates in modern foods. Therefore, how to reduce the bitterness of protein hydrolysate becomes the main technical bottleneck for the development of protein hydrolysate into food. This paper reviews the factors influencing the formation of bitterness and the methods of debittering.

Key words: bitterness; enzymatic hydrolysis; debittering;

Generation of bitterness:

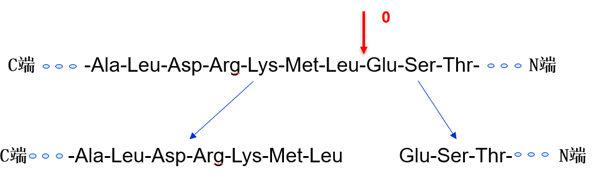

The bitterness of protein hydrolysate mainly comes from hydrophobic polypeptides in the hydrolysate. The natural protein itself has no bitterness for the most hydrophobic side chains are wrapped inside protein molecules and cannot contact with our taste cells; on the other hand, the intact proteins have larger molecular weight and complex molecular configuration, the hydrophobic residue is spatially separated from the taste receptor on the taste bud, so that no bitter taste is produced. After enzymatic hydrolysis of the protein to produce a polypeptide of lower molecular weight, the hydrophobic side chain is exposed and the polypeptide contacts the taste cells to produce a bitter taste. In addition, the presence of hydrophilic groups and basic amino acid residues in the polypeptide also has an effect on the bitter taste of the peptide [2].

There are many factors in the formation of bitterness, the hydrophobicity of bitter peptide [3], the amino acid sequence of the polypeptide (primary structure), the spatial structure of the polypeptide (secondary structure), the molecular weight of the polypeptide, the source of the protein source [4], and the type of protease. Select [5], the degree of proteolysis, etc. will affect the bitter taste of the protein hydrolysate.

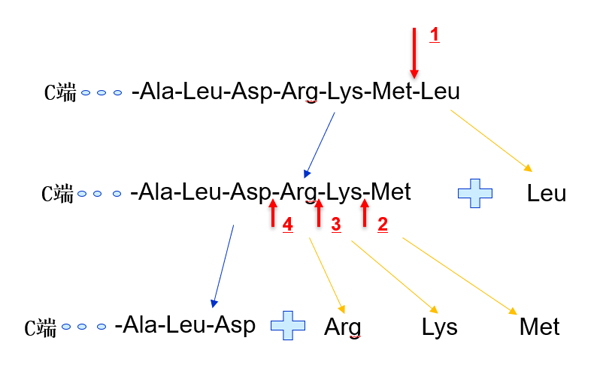

As the enzymatic hydrolysis of the protease proceeds, the macromolecular protein is cleaved from the different sites by the protease to become a small molecule polypeptide. If the end of the polypeptide is a hydrophobic amino acid residue or the polypeptide contains more hydrophobic amino acids. It is easy to combine with bitter taste receptors to produce high-intensity bitterness. Studies have found that the bitter taste of hydrophobic amino acids in monomeric form is much weaker. Common hydrophobic amino acids are tyrosine, tryptophan, phenylalanine, valine, leucine, isoleucine, alanine and methionine [6]. Reducing the proportion of these amino acids in the middle and both ends of polypeptides can greatly reduce the bitterness of proteolytic products.

Solutions provide by Angel:

Angel special enzyme division has developed complex enzyme FF104 and FF106 which can greatly reduce the bitterness of protease hydrolysis. The enzyme is prepared by the selective endonuclease and exonuclease. Endonuclease can efficiently hydrolyze the internal peptide chain of protein, and hydrolyze the large protein into polypeptide. The exonuclease can quickly shear the hydrophobic amino acid at the N end of the polypeptide chain and change into a hydrophilic amino acid at the N end. The bitterness of protease solution was reduced by reducing the proportion of peptides with N terminal as hydrophobic amino acids.

Application process:

Liquid protein solution ---- pH:6.0-6.5, Temp: 50 to 55 ℃----Adding 0.1~0.3% FF104 / FF106---- Reaction for 5-6h ---- Heating to 75 ℃ for 30 mins ---- Add other materials to start Maillard reaction ---- concentration & drying ---- Final products

Example of application

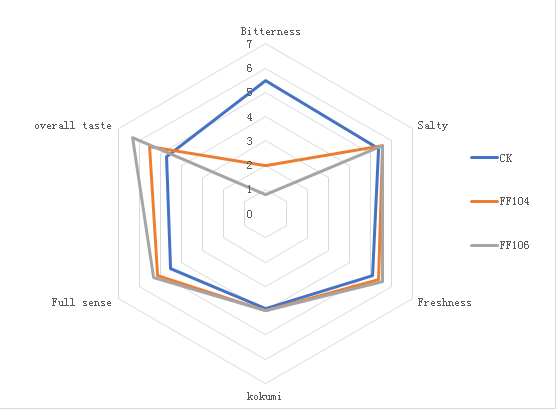

Application of complex enzyme FF104 and FF106 in yeast extract production

Both of the enzyme preparations can greatly improve the bitterness of the product, and have a certain improvement effect on the umami taste, the fullness and the thick taste, and can greatly improve the overall taste of the applied product.

References:

1. Frokjaer,S. Use of hydrolysates for protein in supplementation . Food Technol. 1994,48 (10):86-88.

2. Xu Yonghong, Bitterness control in protein enzymatic hydrolysate, Food industry science and technology.1997,(3):1-4.

3. Jv Yujia, Liang Qi, Yang Min, Research on the formation of bitterness and debittering techniques [J]. Food and machinery , 2013,29(4):246-249.

4. Guo Ling, Yu Guoping, Yang Yongshan, Huo Guicheng, Study on bitter taste of rotein enzymatic hydrolysate, Chinese Food Journal. 2001,1(2):48-50

5. Slattery H,Fizgerald RJ. Functional Properties and Bitterness of Sodium Caseinate Hydrolysates Prepared with a Bacillus Proteinase . J. Food Science .1998,63:418-421.

6. Maehashi K, Huang L, Bitter peptides and bitter taste receptors[J]. Cell Mol Life Sci ,2009,66(10):1661-1671.

Published by Zophi Jin

Senior engineer of Angel Enzyme Division

About AnnzymeTM:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

About Angel :

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86-717-6369520, 6369558

Fax: +86-717-6370680

email: aie@angelyeast.com