OverviewProduct AdvantageProduct Application

OverviewProduct AdvantageProduct ApplicationPHA biomaterials is a generous gift from nature

Product overview

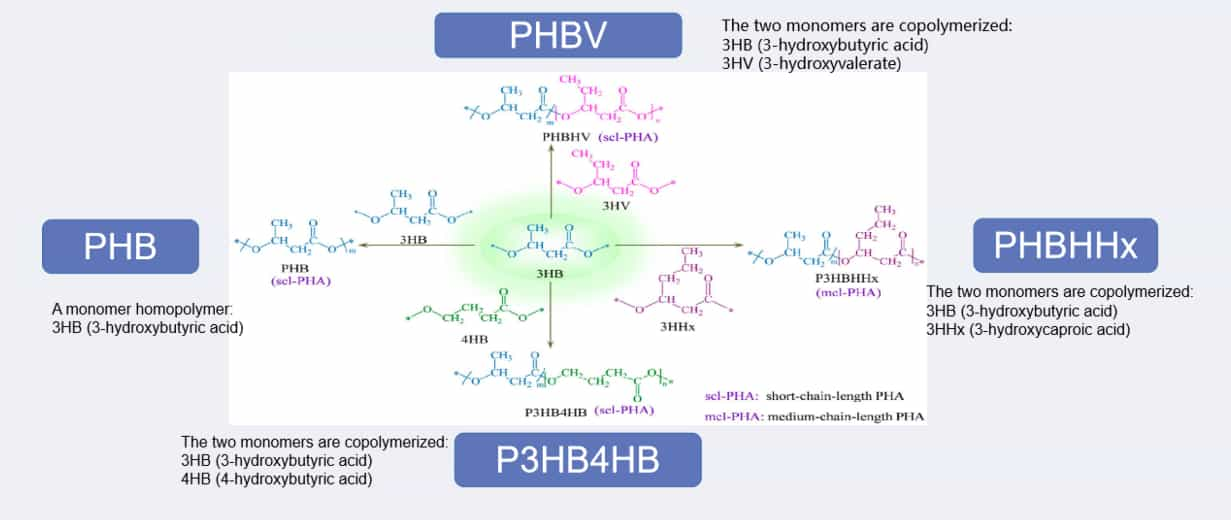

PHA (Polyhydroxyalkanoates) is a polymer biomaterial found in microbial cells such as bacterial cells (similar to bacterial fat).PHA is not only the product of bacteria when the growth conditions are unbalanced, but also the carbon source and energy storage substance in microorganisms.PHA is a polymer consisting of 100-3000 identical or different hydroxyl fatty acid monomers, most of which are 3-hydroxyl fatty acids with chain lengths of 3-14 carbon atoms, and side chains are highly variable aromatic or aliphatic groups.

The latest research shows that there are more than 150 kinds of PHA monomers, which constitute a huge polymer family.The rich and varied material properties and environmentally friendly degradability make it one of the polymers that replace traditional petrochemical plastic products.

PHA Natural Low Carbon Cycle Concept Animation

At present, a total of four types of PHA have been industrialization, including polyhydroxybutyrate (PHB), 3-hydroxybutyrate 3-hydroxyvalerate copolyester (PHBV), 3-hydroxybutyrate 3-hydroxycaproate copolyester (PHBHHx) and 3-hydroxybutyrate 4-hydroxybutyrate copolyester (P34HB), etc., which have their own advantages in practical applications.

PHA product performance can also be compared with other degradable materials

Complementary to enhance material properties

Product brand

| PB3000G | PB3420G | |

Product characteristics | Good rigidity Good barrier Good heat resistance | The strength is adjustable The toughness is adjustable Good heat resistance Excellent barrier property |

Application recommendation | Extrusion molding 3D printing molding Injection molding Thermoforming Casting forming Blow molding Blister molding Suitable for blending modification of PLA, PBAT, PBS etc | |

PHA Performance

| Metrics(Typical Values) | Phamily PHA | Comparison | ||||

| PV3000G | PB3000G | PB3430G | PLA | PBAT | PBS | |

| Density(g/cm3) | 1.25 | 1.25 | 1.23 | 1.26 | 1.23 | 1.26 |

| Melting Point(℃) | 175 | 175 | 170 | 166 | 115 | 114 |

| Glass Transition Temp.(℃) | 0 | 0 | -9 | 60 | -30 | -32 |

| Heat Deflection Temp.(℃) | 130 | 130 | 60 | 56 | 50 | 89 |

| Tensile Strength (Mpa) | 30 | 32 | 12 | 60 | 19 | 40 |

| Tenslle Strength(Mpa) | 1900-2400 | 2200-2700 | 400 | 3630 | 110 | 650 |

| Izod Impact Strength (23℃) (KJ/m") | 2 | 1 | 5 | 1 | 14 | 5 |

| Nominai Tensile Strain at Break(%) | - | 3 | 100 | 6 | 750 | 400 |

| Water Vapor Transmission Rate (0.1mm Thick](g/m²*24h) | 4 | 4 | 10 | 40 | - | - |

| Oxygen Transmission Rate (0.1mm Thick](ml/m*24h) | 6 | 6 | 20 | Surpasses | - | - |

PHA products have good compatiblity and can be blended with each other with adjustable properties | ||||||