-

Home > News & Events > Blog > Enzymes

Soy sauce is a widely used seasoning in Chinese and Asian cuisine, known for its unique flavor and rich nutritional value. In China, there is a saying that "the seven essentials for a household are firewood, rice, oil, salt, soy sauce, vinegar, and tea". Soy sauce holds a significant place in people's daily lives. With the improvement of residents' quality of life, there is a higher demand for traditional seasonings. In the modern pursuit of health and safety, people increasingly prefer soy sauce with zero additives.

Typically, manufacturers produce "zero additive" soy sauce products using materials such as wheat bran and soybean meal, and employing microorganisms such as Aspergillus oryzae, koji mold, and L. acidophilus for fermentation in a high-salt brine.

After a three-month of fermentation, the fresh soy sauce product often has a lower umami intensity and less desirable taste compared to regular soy sauce. Due to the constraints of being "additive-free", it cannot be improved by adding external flavor enhancers such as monosodium glutamate.

Some manufacturers have considered increasing the amount of Aspergillus oryzae used in koji production to enhance the activity of glutaminase produced during fermentation. This aims to effectively break down the abundant glutaminase in the raw materials into glutamic acid to enhance umami flavor. However, it has been found through verification that the salt-tolerant glutaminase from Aspergillus oryzae exhibits poor activity in high-salt concentrations.

Enzyme preparations are food processing aids with a "clean label" attribute. The exogenous addition of glutaminase can significantly enhance the umami flavor of soy sauce.

The Application of Annzyme® Glutaminase in Soy Sauce

Enzyme Selection: Add salt-tolerant glutaminase GLU100 at the beginning of soy sauce fermentation to increase the utilization rate of glutaminase in the raw materials, ensuring complete conversion into glutamic acid to enhance umami.

Enzyme Usage: Dissolve the enzyme powder in the saltwater before adding it to the koji; add all at once.

Enzyme Addition: Recommend adding enzymes at 0.01% (for high-salt liquid state process) or 0.02% (for low-salt solid-state process).

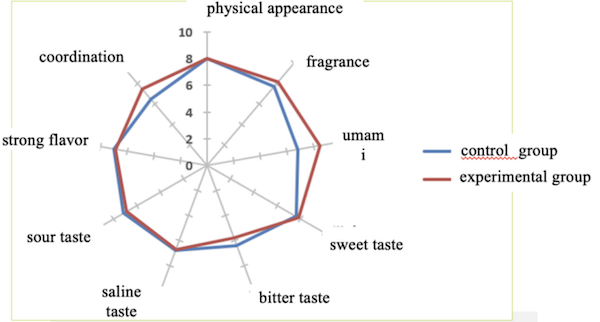

Leveraging years of expertise in the seasoning industry, Angel Enzyme has conducted in-depth enzymatic experiments for soy sauce, exploiting the advantages of the CNAS-accredited laboratory in flavor research. Through extensive identification and analysis of flavor peptides, flavor amino acids, reducing sugars, and electronic tongue flavor evaluation, we have tailored the most suitable enzymatic hydrolysis solution for soy sauce production.

About Annzyme®:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

Press contact:

Angel Yeast Co., Ltd.

Address: 168 Chengdong Avenue, Yichang, Hubei, P. R. China

Tel: +86-717-6369520

Fax: +86-717-6370680

Email: lili@angelyeast.com