-

Home > News & Events > Blog > Enzymes

Sep 5, 2019

By Dong Eric

The quality of wheat flour is influenced by soil, season, climate, rainfall and other factors. In the baking industry, the quality of flour fluctuates greatly due to the different sources of flour. Baking enzymes can solve this problem very well. Angel Special Enzyme has a series of bakery enzymes and solution to solve this problem.

Flour is one of the most important raw materials and subsidiary material in the food industry. With the improvement of people's living standard and the continuous development of the food industry, people put forward higher requirements for the quality of flour and flour food. However, it is well known that the baking industry is plagued by the quality fluctuation due to the different sources of flour.

1 Why does flour quality fluctuate?

High quality wheat raw materials are needed to produce good special flour. Tracing back to the source --- on the quality of wheat. The growth process of wheat is mainly affected by factors such as soil, season, climate, rain and so on. The difference of soil conditions in different regions leads to the abrupt increase and an abrupt decrease of wheat protein content. In the harvest season, excessive rainfall may lead to wheat germination. The endogenous alpha-amylase activity of germinating wheat differs greatly from that of normal wheat, which indirectly affects falling number of flour.

The quality of wheat from different sources is uneven, so many flour mills choose to mix several flours with different characteristics in order to reduce the product instability caused by the fluctuation of wheat quality, but this still can not fundamentally solve the situation of flour quality instability.

2 The problem facing in flour improver

It is an effective method to choose the appropriate improver in flour. With adding these ingredients can not only maintain the uniformity of flour, but also improve the quality of flour. For a long time in the past, most of the improvers used in flour were chemicals, which improved the quality of flour to a certain extent. However, with the consumers’ awareness on food safety and the continuous progress of food industry technology, the potential hazards of chemical additives used in flour have also attracted more attention.

3 The application of enzymes in flour industry

Food industry and consumers urgently need healthy, natural and pollution-free flour improvers. Enzymes meet this requirement well, for it comes from organisms (animals, plants, microorganisms) and is a kind of protein. Many of them which are made by modern biotechnology are pure natural biological products and green food additives. They are widely used in grain processing and other food processing, so the application in flour industry has already attracted people's attention. Enzymes play an important role in the production and improvement of all kinds of special flour and help flour industry to realize flour standardization.

At present, the flour mill chooses the most are alpha-amylase and xylanase, which are widely used to regulate the quality of various flour and improve the quality of flour products.

Function: Adjust the falling number of flour, increase the saccharification ability of flour and improve the baking performance of flour.

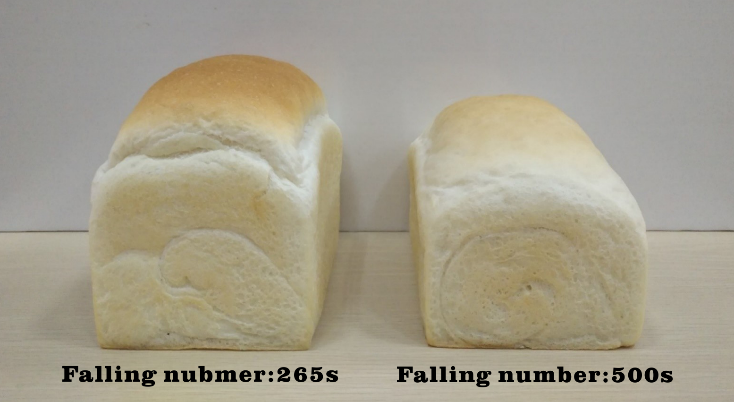

How to judge the deficiency of endogenous α-amylase in flour? By the experience accumulated in baking, or the falling number is about 250s, which can better meet the needs of baking products.

When the falling number is high, it is necessary to add α-amylase to reduce it.

The addition of α-amylase hydrolyzes damaged starch into dextrin and maltose, which provides a sugar source for yeast fermentation. Sugar produced can also improve flavor and enhance surface color of bread. Meanwhile it can supplement the deficiency of endogenous α-amylase in flour, increase the volume of the product, and ensure dough with a more uniform structure.

It was found that fungal α-amylase was completely inactivated when the oven temperature reached 75℃, and there was no residue in bread after baking. Bacterial α-amylase had high thermal stability, and the activity of bacterial α-amylase still exist after baking, although the central temperature of bread reach 95℃ during baking. It causes excessive saccharification of bread core to lead a negative impact on the quality of bread. Therefore, it is right to choose fungal α-amylase in baking.

Function: Help to adjust the air holding capacity and extensibility of dough and improve the quality of baking products.

Water-insoluble xylan could be bind to gluten protein, which hindered the formation and expansion of gluten. After xylanase degraded xylan, it increased the extensibility and stability of dough, formed softer and flexible dough, and eventually produced larger volume and more uniform tissue.

Non-starch polysaccharide NSP in flour can absorb about 10 times water than its own weight. The main component of NSP is arabinoxylan, which can be degraded by endo-xylanase. Through releasing the water absorbed by NSP, it ensure starch absorbs enough moisture during the gelation stage.

|

Published by Dong Eric Institute of Special Enzymes and Biological Products |

About AnnzymeTM:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

About Special Enzyme Division :

Angel Special Enzyme Division is an important strategic business unit of Angel Yeast. Related technologies involve the fields of microbial breeding, genetic engineering, fermentation engineering, biocatalysis, food, brewing, feed, pharmaceutical, etc.

About Angel :

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel& Fax: +86-717-6369520

Email: enzyme@angelyeast.com