-

Home > News & Events > Blog > Enzymes

Apr. 15, 2020

You should have the experience that bread is soft, moist and delicious when it's just out of the oven, but when it's placed for a long time, it becomes harder and harder, and gradually loses its original elasticity and wetness.

For this reason, people have been studying various additives to prolong the shelf life of bread and reduce the economic loss to the greatest extent.

The aging mechanism of bread is not clear for now, but there are many reports show that the change of texture is due to the recombination of starch components, especially the highly branched amylopectin molecules, or the absorption of more water in the process of starch gluten cross winding, which increases the number of gluten forming complex in flour.

Here we recommend a big family, maltogenic amylase, which can effectively solve the aging problem in baking.

Maltogenic amylase

It has a unique anti-aging effect, which can specifically degrade amylopectin to produce maltose and a small amount of dextrin, retard the retrogradation of starch, thereby extending the shelf life of bread and reducing waste by maintaining the elasticity, softness and freshness of bread.

MAM100 is an elfin of the Annzyme® baking enzyme family. It was born in the maltogenic amylase family and can give the softness core during the preservation of bread and meet the elastic demand of the core.

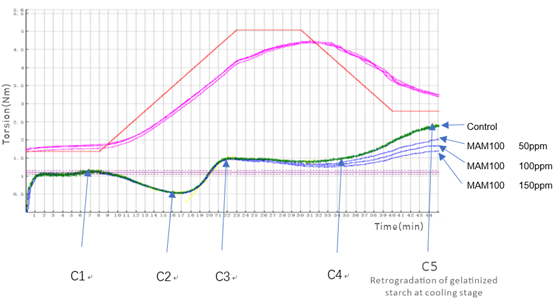

We select high-quality flour, add different amount of MAM100 to carry out experiment to test the retrogradation characteristics of starch through Mixlab.

Fig.1 The retrogradation characteristic curve of MAM100 working on starch with different dosage

(Note: the C5 value decreases with the addition of MAM100. The lower the C5 value, the better the anti-aging effect of the enzyme is.)

It was also found that maltogenic amylase showed high activity at the temperature of starch gelatinization, but very low activity below 35 ℃. Therefore, maltogenic amylase does not change the flour properties of dough. The thermostability of maltogenic amylase is between fungal α-amylase and heat stable bacteria α-amylase which still plays a role in the baking process as well as is inactivated in the final stage of baking. So maltogenic amylase will not lead to excessive decomposition of starch.

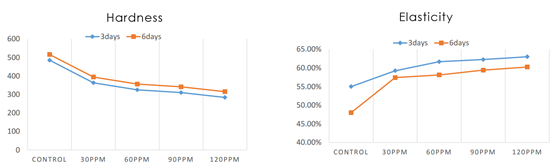

Fig.2 Study on the hardness and elasticity of bread with different dosage of MAM100

Therefore, we use maltogenic amylase to solve the problem of bread aging and slagging in baking, and also we do not have to worry about the risk of excessive addition.

| Published by Eric Dong Institute Of Special Enzymes and Biological Products |

Related product please check:

https://en.angelyeast.com/products/enzymes/Maltogenic%20Amylase.html

About Annzyme®:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

About Special Enzyme Division :

Angel Special Enzyme Division is an important strategic business unit of Angel Yeast. Related technologies involve the fields of microbial breeding, genetic engineering, fermentation engineering, biocatalysis, food, brewing, feed, pharmaceutical, etc.

About Angel :

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel& Fax: +86-717-6369520

Email: enzyme@angelyeast.com