Through the process of feed pelleting, the processing of feed components into pellets has become the norm, and is widely used in pig, poultry, aquatic and ruminant feed, etc. Compared with powdery feed, pellet feed can reduce the picky eating phenomenon of animals as much as possible, reduce feed waste and improve feed utilization rate; At the same time, in the production process of pellet feed, it is necessary to apply high temperature, high humidity can kill the pathogen in feed raw materials to a certain extent; In addition, with the automation of modern breeding, pellet feed is more convenient in transportation, storage, use and other aspects. However, due to the great stress of feed pelleting conditions, some traditional high-efficiency feed additives, such as enzyme preparations and probiotics, may have the risk of decreasing their activity when used. The new feed additive products such as active enzyme preparation and probiotics which can tolerate the feed granulation environment are particularly important. Here we will focus on YeaVita R+, a Saccharomyces cerevisiae product dedicated to ruminant pellet feed with high tolerance.

1.What is YeaVita R+

YeaVita R+ is a coated and heat stable live yeast, produced by submerged fermentation of specially selected strains of saccharomyces cerevisiae from rumen (Saccharomyces cerevisiae CCTCC M205128), mainly used for pelleting feed for ruminant. YeaVita R+ is a coated and heat stable YeaVita R, which can remain viable throughout industrial pelleting processes. Live yeast count≥10 billion/g.

2. Why it is stable during pelleting

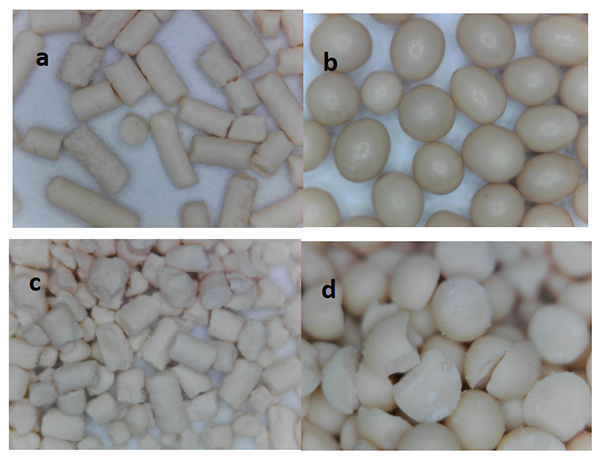

YeaVita R+ has been coated by special embedding and drying process, and a dense and compact spherical shell is formed on the surface which means it can prevent hot and humid steam from entering the interior, and more effectively protect the internal yeast surviving under high temperature and high humidity conditions during feed pelleting; What’s more, the internal structure of YeaVita R+ is also very dense, which can effectively resist the mechanical pressure and avoid directly exposure to the granulation environment after being crushed compared to the normal products, such as YeaVita R (Fig 1).

Fig 1 Compare YeaVita R(a, c)with YeaVita R+ (b, d) for appearance and morphology

(Note:a、b: intact product;c、d: crushed product)Most importantly, we has use different methods to assess the high temperature resistance capacity for these two kinds of products.

Test 1: Dry heat tolerance test(in laboratory)

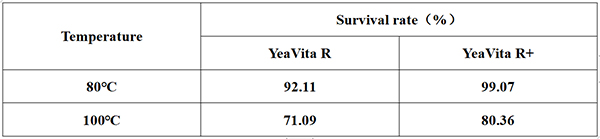

The results of the dry heat high temperature tolerance experiment showed that when YeaVita R and YeaVita R+ in the test tube were heated for 3 minutes by 80 ℃ and 100 ℃ water bath, both all have better survival rate, but the survival rate of YeaVita R+ under dry heat conditions is 6.96% and 9.29% higher than YeaVita R, respectively (Table 1).

Table 1 Survival rate of YeaVita B and YeaVita B+ in water bath

Note:Take 5g of each sample in a sterile glass test tube, plug the test tube plug, put it in a water bath of different temperature for 3 minutes, take it out and do gradient dilution, then cultured with plate and count, calculate the survival rate.

Test 2: Damp heat tolerance test(in laboratory)

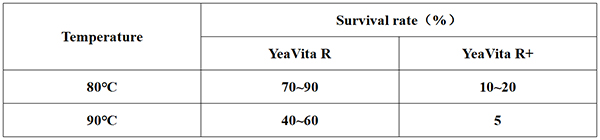

The results showed that the survival rate of YeaVita R was significantly lower than that of YeaVita R+ by comparing ordinary type active dry yeast products and high temperature resistant active dry yeast products at 80℃ and 90℃ for 3min by steam sterilization pot (Table 2).

Table 2 Survival rate of YeaVita B and YeaVita B+ in steam sterilization pot

Note:Take 20~50g of each sample and wrap in sterile gauze, plug the test tube plug, put it in a steam sterilization pot of different temperature for 3 minutes, take it out and do gradient dilution, then cultured with plate and count, calculate the survival rate.

Test 3: Feed pelleting test(in feed factory)

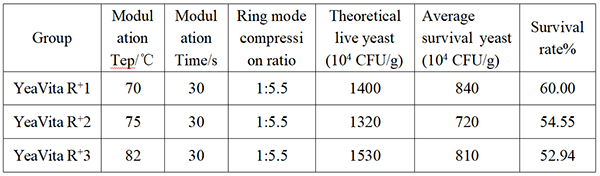

Three batches of YeaVita R+were selected for pelleting in a large scale feed factory, and the product added amount was 1kg/t. The results of feed pelleting (high temperature and high humidity) showed that the survival rate of YeaVita B+ is between 58 and 68%, while the survival rate of YeaVita B is less than 1% which means YeaVita B+ has a good tolerance under the conditions of high temperature, high humidity and ring mold compression prepared during feed granulation (Table 3).

Table 3 Survival rate of YeaVita B and YeaVita B+ after pig feed pelleting

3. What's the function of YeaVita R +

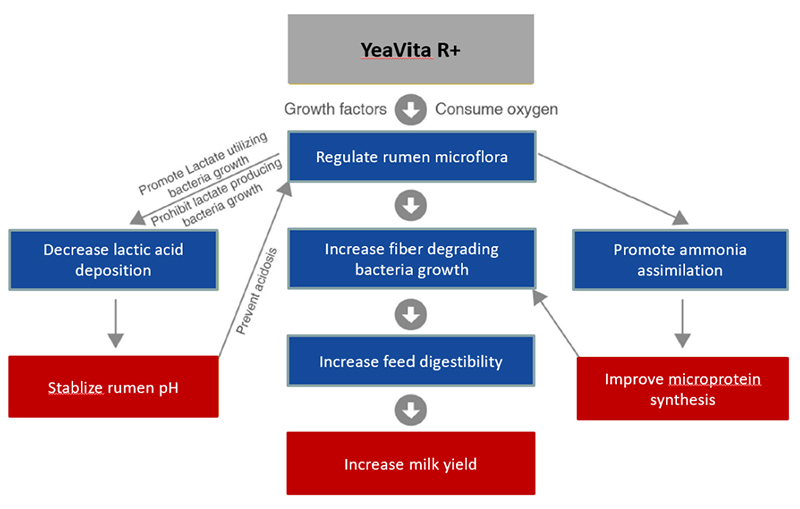

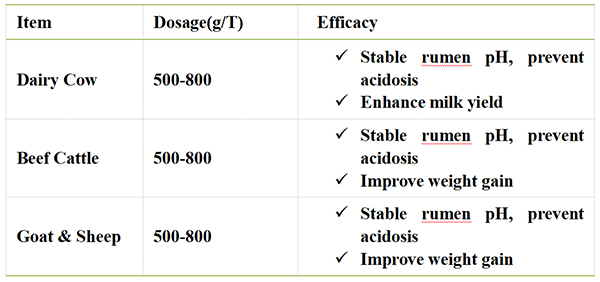

YeaVita R+ as a kind of special probiotic for ruminants, such as dairy cows, cattle, beef, sheep and so on, it is very helpful to create a better rumen environment by regulate the rumen microflora, and then improve the fiber digestibility, stabilize the rumen pH which can prevent the acidosis. At last, for the animals, it can improve the milk yield and growth performance.

The detail recommendation and function for YeaVita R+ are as follow:

| Published by Gong Fayuan Senior Engineer of Animal Nutrition Division |

About Angel Animal Nutrition:

Fubon is a brand of Angel Animal Nutrition. Fubon is committed to developing natural, efficient microbial feed derived from yeast with Angel's leading technology in yeast industry, providing the best service solutions for the nutrition and health in animals. Angel Animal Nutrition creates value for global feed and animal agriculture customers through continuously upgraded products and professional services.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press Contact:

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel:+86-717-6369520, 6369558

Fax:+86-717-6370680

email: aie@angelyeast.com