Mar.31, 2020

By Carl

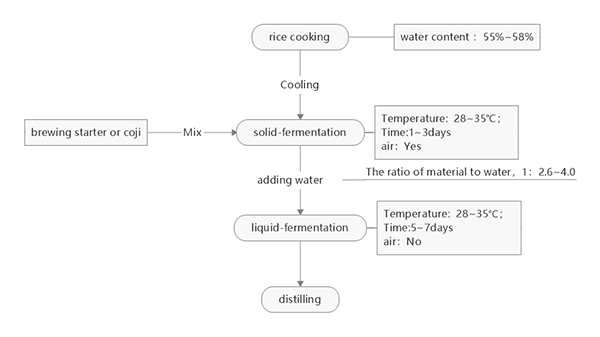

Half-solid fermentation is a common way to make alcohol beverage in many Asian countries. Its low equipment requirement and easy handing can be used in many kinds of scale from industrial production to the home workshop. As an engineer of fermentation, there are some devices about the temperature to the operator when they were brewing.

What is the best temperature to half-solid fermentation

Sometimes, we said that, temperature is the only thing you should notice in the brewing process. We all know that the microorganism is the real worker in fermentation system, but you can not see its state and control it directly. So, the temperature is the easiest thing that you can measure and control. By the other side, the temperature can reflect the state of microorganism.

In the solid fermentation part, the whole system temperature should be kept between 28~35℃.

In fact, it is not a real fermentation process in front of the solid part. Most of the time in this process is to make the microorganisms, include rhizopus and yeast, grow quickly and numerously. So, at the end of this process, there are enough microorganisms to produce enzymes and ready for ethanol fermentation. The best temperature for yeast and mold’s growth is between 28~35℃。

Theoretically, if the temperature is lower than 28℃, the effective microorganism’s growth will be get slower according to the number of microorganism is not enough to release enzymes and make ethanol fermentation. but if the temperature is more than 36℃, the yeast growth will be stopped, and on the other side , this temperature will be suitable for some bacteria, it will be a big potential danger for all the system.

In the liquid fermentation part, the whole system temperature should be kept between 30~38℃.

The liquid fermentation part is a primary process in this system. It is easy to understand the working principle. It is a little different from the liquid fermentation part of half-solid fermentation to pure liquid fermentation. Generally, in most of pure liquid fermentations, the enzymes will degrade the material first and then let the yeast to start its ethanol producing. But, liquid fermentation in half-solid process is what we call bilateral fermentation, it means that the enzymolysis and ethanol fermentation goes at the same time.

When adding water, the liquid part fermentation started. Generally, ferment power will be at highest level on the second and third day. You must pay some attention to this period. Fermentation is exothermic, which means it will create its own heat. So, if the temperature is over than 38℃. There are some problems may be happened. First, it is possible to make the yeast to over aging and let the whole system in danger. Second, a higher growth temperature will change the yeasts metabolism, producing a different range of by-products, which can have a major effect on flavor such as ester and fusel alcohol production. So, Having the ability to cool the fermentation once it starts to take off is an imperative. Generally, liquid fermentation is 5~7days at most of the condition, then all the mash can be distilled.

Common half-solid fermentation process and control points

| Published by Carl Senior Engineer of Distilled Spirits and Biofuels Division |

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

For more media information, please contact:

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: wusy@angelyeast.com

en.angelyeast.com