Angel Yeast: Your reliable fermentation partner of Biotechnology

Angel Yeast is a world-leading biotechnology company dedicated to yeast and deep-processing products. With 12 dedicated R&D centers and over 760 full-time researchers, the company operates manufacturing facilities in 11 cities globally, including Egypt, boasting a total fermentation capacity of 350,000 metric tons annually. Its products reach over 170 countries and regions, holding over 15% globally. Angel Yeast ranks as the world's second-largest producer of yeast series products.

Robust Research & Development Foundation

The company possesses a National Enterprise Technology Center and a Postdoctoral Research Workstation. Its testing center holds CNAS laboratory accreditation. Angel Yeast has secured 324 authorized invention patents and has led or participated in formulating all national and industry standards for the yeast sector. Its achievements include 2 National Science and Technology Progress Awards and 33 Provincial/Ministerial Science and Technology Progress Awards.

Uncompromising Quality Control

"Product quality is the lifeblood of the enterprise. Our commitment: Never compromise on quality and food safety." Angel Yeast adheres to a quality policy of "Source Control, Prevention First, Pursuit of Zero Defects." This involves:

1. Strengthening quality awareness training for all employees.

2. Rigorous supplier evaluation and selection for source control.

3. Comprehensive implementation of advanced management systems across all operations.

4. Establishing key control point monitoring systems and building a traceability system for full-process control and international compliance.

5. Operating standardized testing centers within each factory for robust quality support.

6. Implementing a streamlined process for resolving quality issues to protect client interests.

7. Continuous adoption of Performance Excellence Management models has earned Angel Yeast widespread recognition for its operational quality.

Specialized Yeast OEM Advantages

I. R&D Expertise:

Possesses a complete R&D system: Yeast strain screening -> Basic performance analysis -> Lab-scale trials -> Pilot trials -> Large-scale trials -> Product testing. Equipped with lab-scale fermentation tanks (1.5L, 5L, 45L, 100L) and pilot-scale fermentation tanks (10m³, 60m³, 80m³). Employs 6 senior technical experts with over 30 years of Active Dry Yeast (ADY) experience, nearly 50 specialized fermentation technicians, and over 80 ADY application technicians. Accumulated extensive experience in specialized yeast high-density fermentation, yeast cell size control, high-cell-count ADY production, and high-activity ADY application technology.

R&D scope covers specialized ADY for Baijiu, Fuel Ethanol, Beer, Wine, Whisky, Beverages, Bio-feed, Agriculture, and more. Maintains independent platforms for strain preservation, fermentation technology, and application testing (Baijiu, Wine, Beer, Whisky), alongside a comprehensive bio-fermentation analysis platform.

II. Manufacturing Excellence:

Operates over 10 intelligent ADY manufacturing plants globally, capable of categorized production and quality control for diverse yeast products. Each plant utilizes mature process control and quality management systems.

Production lines employ SIMATIC PCS7 control systems for online monitoring and automatic feedback of critical fermentation parameters (DO, pH, CER, OER, Alcohol, Temperature, Airflow), ensuring exceptional process stability. Secured ample resources of key raw materials (sugarcane molasses, beet molasses, starch sugar). Features production tanks of various capacities (160m³, 360m³, 460m³) and possesses advanced hardware/software systems for high-density yeast fermentation. Holds a distinct competitive edge in ADY production capacity, product quality stability, and cost control.

III. Superior Product Quality:

Continuously refines fermentation processes to control yeast cell size, uniformity, and maturity, reinforcing ADY manufacturing quality leadership. Integrates high-end process monitoring equipment and modern high-throughput cell analysis to pioneer control methods enhancing yeast cell uniformity during fermentation, reducing inter-cell variability and optimizing population performance.

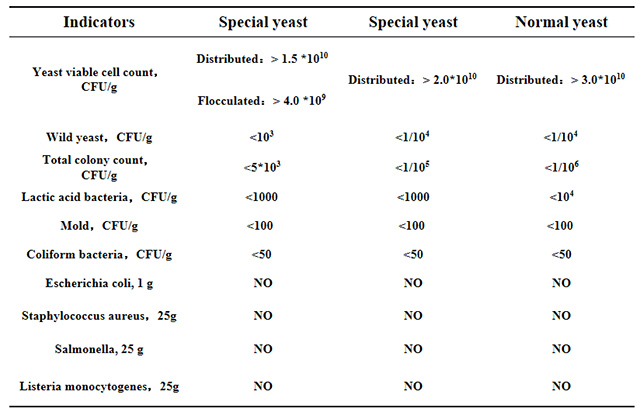

Implements strict microbial control: SOPs and work instructions govern all production stages (PC Seed, Commercial Fermentation, Yeast Cream Separation, Drying, Packaging, Finished Product). Microbial indicators are tested at each step. Quality control standards significantly exceed industry requirements.

Table 1: Quality Specifications of Angel Yeast Dry Yeast Products

IV. Collaboration & Management:

As an international biotech enterprise, Angel Yeast operates under mature, comprehensive quality management systems and robust client technical confidentiality protocols. Maintains a specialized team for contract business negotiation and project management. Delivers professional, trustworthy, and reliable customized yeast contract manufacturing services. Upholds the corporate spirit of "Pursuing Satisfaction, Never Complacent" to provide clients with the most confidential, secure, and premium yeast contract manufacturing solutions.

Tailored Yeast Solutions: From R&D to Production

Partner with us to transform your biotechnology initiatives through customized specialty yeast processing, collaborative R&D projects, and seamless commercialization of novel yeast strains. We deliver integrated solutions from lab development to full-scale production and distribution, supported by shared research platforms and expert technical guidance. Leverage our cutting-edge fermentation technologies and strain optimization expertise to accelerate product innovation, enhance yield efficiency, and achieve scalable, market-ready outcomes—all backed by robust application support tailored to your industry needs.

| Published by Zheng Ping Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com