As one of the world's most influential distilled spirits, the quality and style of whisky are highly dependent on terroir, raw material selection, distillation processes, and maturation techniques. Due to differences in climate, water sources, oak cask types, and traditional craftsmanship across various regions, distinctly recognizable flavor profiles have been formed.

For whisky distilleries, the selection of suitable brewing yeast is crucial. Whisky yeast is capable of fermenting macromolecular carbohydrates such as maltotetraose and small-molecular dextrins, while also exhibiting higher tolerance to fermentation environment stress. Yeast is a key factor influencing aroma variations during whisky production. A growing body of research indicates that yeast selection exerts a significant impact on the flavor and aroma of whisky. Different yeasts affect the final aromatic components and flavor characteristics during both fermentation and distillation processes. The aromatic and flavor compounds in whisky interact to produce a synergistic effect, among which ester compounds (e.g., ethyl acetate, ethyl butyrate) and alcohol compounds (e.g., ethanol, isoamyl alcohol) collectively shape the rich and unique aroma of whisky.

AM-MAX is a type of yeast designed for malt whisky production. It features fast initial fermentation, strong fermentative performance, and the ability to generate complex ester aromas, endowing whisky with multi-layered floral and fruity notes that perfectly meet the fermentation requirements of single malt whisky. Its NEW MAKE (newly distilled, unaged spirit) exhibits elegant and rich fruity aromas, including delicate fruit scents such as green apple, pear, peach, pineapple, and kiwi. The optimal fermentation temperature for AM-MAX ranges from 22 to 32°C, and it possesses excellent ethanol tolerance, maintaining good fermentation efficiency even under high-sugar substrate conditions. As an innovative yeast specifically engineered for malt whisky brewing, AM-MAX is an ideal choice for single malt whisky production.

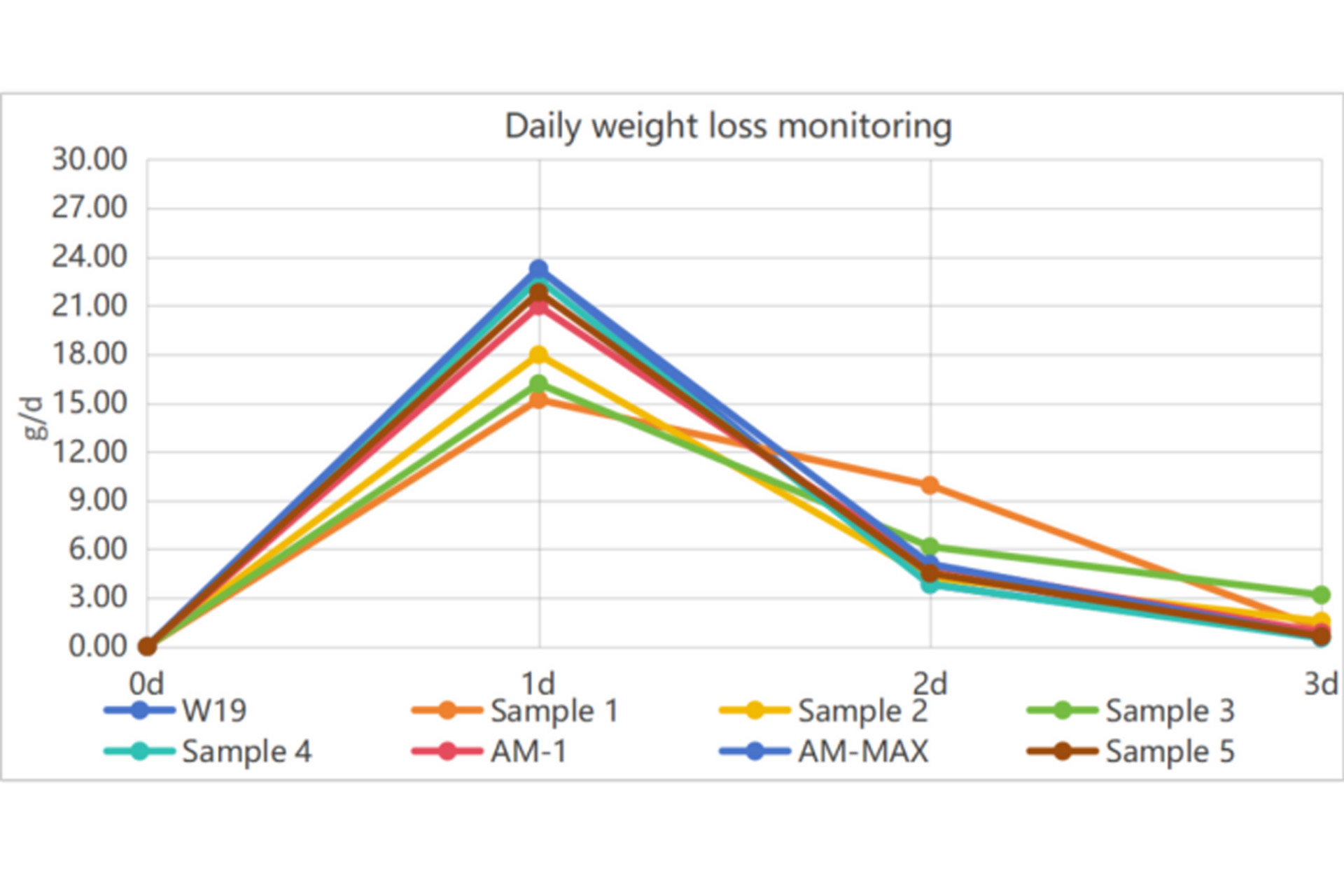

The fermentation kinetic curve of whisky yeast is plotted by measuring the daily weight loss and cumulative weight loss during the fermentation process.

(Initial Specific Gravity: 1.066; Fermentation Conditions: 30℃, 72 h)

By monitoring the trend of weight loss curves between the new whisky yeast AM-MAX and the control samples, it was observed that AM-MAX exhibited a higher daily weight loss than the other experimental samples. The fermentation of AM-MAX was completed at 72 hours, and it achieved the highest cumulative weight loss. These results demonstrate that AM-MAX possesses excellent fermentative characteristics, which can meet the brewing requirements of single malt whisky.

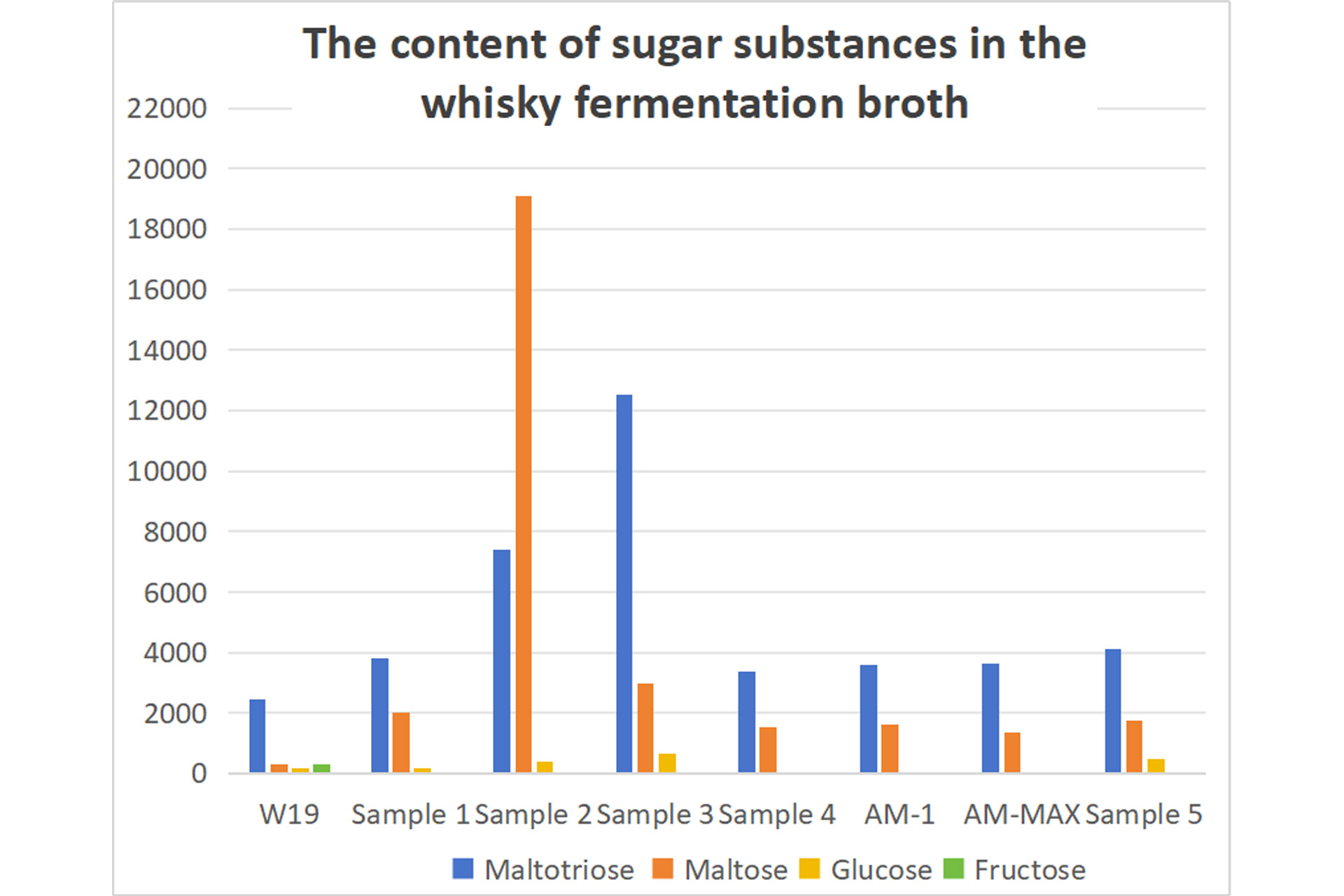

The content of carbohydrate substances in the whisky fermentation broths of different yeasts was determined via high-performance liquid chromatography (HPLC). Differences in saccharification capacity among various yeasts resulted in significant variations in the contents of maltose and maltotriose. The contents of maltose and maltotriose in the fermentation broth of AM-MAX were only lower than those of W19, indicating that AM-MAX possesses favorable saccharification capacity. Additionally, AM-MAX exhibited the best utilization efficiency for fructose and glucose.

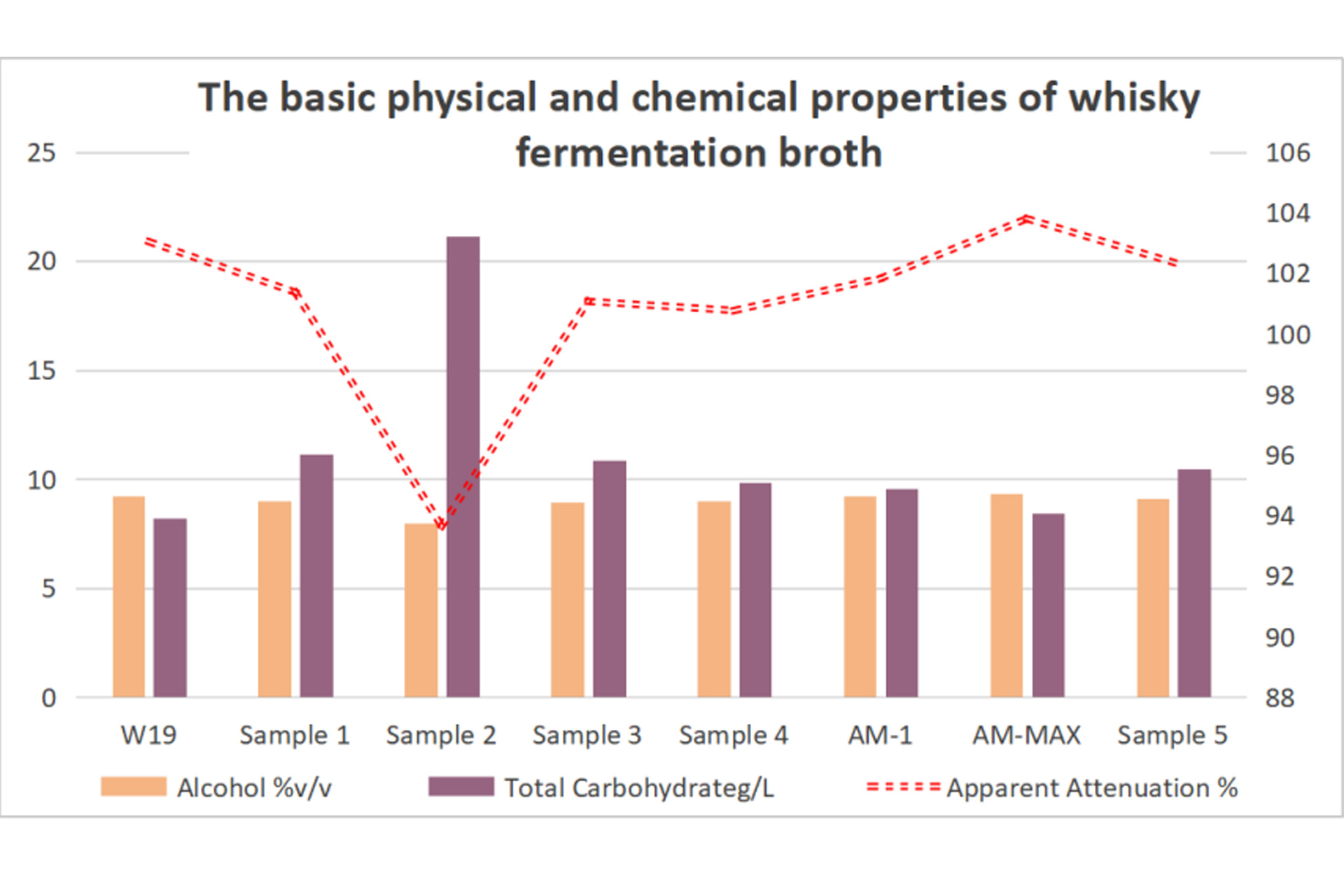

The physicochemical indices of the whisky fermentation broths were tested. Compared with single malt whisky yeasts such as Sample 1, Sample 2, Sample 3, Sample 4, and Sample 5, AM-MAX exhibited the highest alcohol content and apparent fermentation degree, making it a high-quality single malt whisky yeast.

When AM-MAX was applied in whisky wort, it achieved an alcohol content of 9.34% v/v and a fermentation degree of 103.75%, with fermentation capacity higher than that of the other samples. Moreover, compared with Sample 3 (a common single malt whisky yeast available on the market), AM-MAX showed an increase of 4.6% v/v in alcohol content, demonstrating excellent fermentative performance.

Analysis of Volatile Flavor Compounds in Whisky Fermentation Broth

Estimated Concentration (mg/L) | W19 | Sample 1 | Sample 2 | Sample 3 | Sample 4 | AM-1 | AM-max | Sample 5 | |

Content of Ester Compounds | Ethyl Acetate | 0.87 | 0.31 | 0.66 | 0.88 | 1.19 | 0.62 | 0.71 | 0.79 |

Isoamyl Acetate | 3.47 | 3.68 | 2.09 | 8.85 | 16.03 | 4.57 | 7.54 | 7.14 | |

Ethyl Caproate | 3.87 | 7.62 | 3.98 | 9.84 | 8.19 | 4.63 | 6.56 | 7.92 | |

Ethyl Caprylate | 20.25 | 33.77 | 17.85 | 63.42 | 44.10 | 20.53 | 64.52 | 39.43 | |

Ethyl Caprate | 12.41 | 53.80 | 14.22 | 46.64 | 24.28 | 26.48 | 54.86 | 37.56 | |

Ethyl Benzoate | 0.44 | 0.16 | 0.30 | 0.18 | 0.25 | 0.53 | 0.06 | 0.23 | |

Isoamyl Octanoate | 0.00 | 0.46 | 0.29 | 1.75 | 1.72 | 0.00 | 0.54 | 0.35 | |

Ethyl 9-Decenoate | 4.26 | 5.97 | 7.45 | 11.37 | 25.32 | 1.84 | 15.95 | 12.10 | |

Decyl Caprate | 0.23 | 0.47 | 0.00 | 0.00 | 0.00 | 0.00 | 0.53 | 0.40 | |

Ethyl Phenylacetate | 0.00 | 0.05 | 0.03 | 0.11 | 0.00 | 0.05 | 0.06 | 0.00 | |

Phenethyl Acetate | 8.79 | 9.60 | 10.91 | 17.43 | 21.11 | 7.56 | 17.52 | 11.10 | |

Ethyl 3-Methylbutanoate | 0.00 | 0.12 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

Ethyl Laurate | 5.40 | 42.79 | 5.87 | 19.86 | 17.34 | 15.12 | 18.27 | 14.86 | |

3-Methylbutyl Caprate | 0.26 | 0.94 | 0.21 | 1.48 | 0.66 | 0.00 | 0.00 | 0.65 | |

Isobutyl Laurate | 0.00 | 0.08 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

Isoamyl Laurate | 0.00 | 0.39 | 0.00 | 0.48 | 0.00 | 0.00 | 0.27 | 0.00 | |

Ethyl 3-Hydroxytridecanoate | 0.32 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

R-γ-Decalactone | 0.00 | 0.00 | 0.05 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

Phenethyl Caproate | 0.14 | 0.43 | 0.16 | 0.36 | 0.00 | 0.00 | 0.00 | 0.00 | |

Ethyl 9-Hexadecenoate | 2.61 | 3.99 | 0.00 | 0.00 | 0.00 | 0.00 | 0.25 | 0.00 | |

γ-Heptalactone | 0.00 | 0.00 | 0.00 | 0.00 | 0.05 | 0.06 | 0.00 | 0.00 | |

2-Methylbutyl Laurate | 0.00 | 0.00 | 0.00 | 0.00 | 0.26 | 0.00 | 0.00 | 0.00 | |

Ethyl 9-Tetradecenoate | 0.00 | 0.00 | 0.00 | 0.00 | 0.54 | 0.00 | 0.00 | 0.00 | |

2-Phenethyl Caproate | 0.00 | 0.00 | 0.00 | 0.00 | 0.25 | 0.00 | 0.25 | 0.07 | |

Isoamyl Dodecanoate | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.13 | 0.00 | 0.23 | |

Phenethyl Caproate | 0.00 | 0.00 | 3.08 | 0.00 | 0.00 | 0.31 | 0.11 | 0.42 | |

Ethyl 9-Hexadecenoate | 0.00 | 0.04 | 4.87 | 11.28 | 11.99 | 2.96 | 14.40 | 6.09 | |

Ethyl Stearate | 0.16 | 0.31 | 0.14 | 0.48 | 0.18 | 0.11 | 0.24 | 0.09 | |

Ethyl Elaidate | 0.00 | 0.00 | 1.02 | 3.53 | 2.56 | 0.00 | 2.26 | 1.54 | |

Total | 63.47 | 164.98 | 73.17 | 197.92 | 176.02 | 85.49 | 204.88 | 140.99 | |

Content of Alcohol Compounds | Isobutanol | 2.06 | 0.68 | 0.63 | 0.92 | 1.31 | 0.66 | 1.48 | 0.82 |

Isoamyl Alcohol | 52.18 | 23.23 | 27.69 | 40.26 | 60.03 | 27.85 | 40.09 | 32.23 | |

2,3-Butanediol | 0.10 | 0.20 | 0.15 | 0.25 | 0.38 | 0.21 | 0.16 | 0.67 | |

1-Octanol | 0.06 | 0.15 | 0.12 | 0.04 | 0.06 | 0.16 | 0.08 | 0.10 | |

2,6,8-Trimethyl-4-nonanol | 0.03 | 0.03 | 0.02 | 0.25 | 0.25 | 0.03 | 0.25 | 0.37 | |

3-(Methylthio)-1-propanol | 0.31 | 0.17 | 0.20 | 0.00 | 0.50 | 0.16 | 0.00 | 0.43 | |

1-Decanol | 0.00 | 0.00 | 0.42 | 0.12 | 0.46 | 0.42 | 0.00 | 0.00 | |

Phenethyl Alcohol | 70.40 | 46.56 | 58.04 | 71.99 | 57.66 | 54.22 | 84.77 | 53.26 | |

Citronellol | 0.41 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

trans-Nerolidol | 1.58 | 0.37 | 0.69 | 0.78 | 0.64 | 0.38 | 0.62 | 0.50 | |

Farnesol | 0.91 | 0.46 | 0.52 | 0.72 | 0.49 | 0.77 | 0.51 | 0.56 | |

Total | 128.04 | 71.83 | 88.49 | 115.34 | 121.78 | 84.87 | 127.96 | 88.96 | |

Acids and Others | Acetic Acid | 0.23 | 0.12 | 0.52 | 0.28 | 0.15 | 0.45 | 0.37 | 0.37 |

n-Caproic Acid | 0.63 | 0.89 | 0.42 | 1.32 | 0.84 | 0.54 | 1.42 | 0.98 | |

Caprylic Acid | 16.78 | 30.05 | 12.27 | 31.90 | 25.33 | 15.44 | 20.97 | 25.48 | |

Capric Acid | 19.68 | 31.45 | 4.73 | 24.64 | 17.79 | 10.02 | 23.35 | 20.19 | |

9-Decenoic Acid | 1.17 | 1.11 | 0.64 | 1.99 | 3.68 | 2.02 | 1.26 | 1.83 | |

Lauric Acid | 1.72 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

1,2-Benzenedicarboxylic Acid | 0.00 | 0.05 | 0.04 | 0.07 | 0.00 | 0.00 | 0.00 | 0.00 | |

Benzaldehyde | 0.07 | 0.05 | 0.11 | 0.00 | 0.05 | 0.05 | 0.00 | 0.06 | |

2-Phenylacetaldehyde | 0.06 | 0.00 | 0.05 | 0.08 | 0.06 | 0.04 | 0.06 | 0.00 | |

Coconut Aldehyde | 0.07 | 0.05 | 0.00 | 0.05 | 0.00 | 0.00 | 0.05 | 0.00 | |

p-Vinylguaiacol | 1.19 | 0.22 | 3.22 | 4.24 | 4.57 | 3.64 | 4.62 | 1.11 | |

2,4-Di-tert-butylphenol | 0.37 | 0.00 | 0.23 | 0.29 | 0.24 | 0.29 | 0.19 | 0.23 | |

2-Nonanone | 0.15 | 0.00 | 0.04 | 0.00 | 0.00 | 0.07 | 0.00 | 0.11 | |

2-Methyltetrahydrothiophene | 0.44 | 0.00 | 0.14 | 0.00 | 0.40 | 0.29 | 0.00 | 0.20 | |

2,3-Dihydrobenzofuran | 0.12 | 0.00 | 0.24 | 0.52 | 0.39 | 0.28 | 0.60 | 0.14 | |

Total | 42.69 | 64.00 | 22.65 | 65.37 | 53.51 | 33.13 | 52.89 | 50.71 |

In the fermentation broth of AM-MAX, the total ester content was 204.88 mg/L, the total alcohol content was 127.96 mg/L, and the content of acids, phenols, and other substances was 52.89 mg/L. The relatively high ester content imparts rich floral and fruity aromas to it, while the relatively high total alcohol content also endows it with certain flavor characteristics.

In the fermentation broth of Sample 3, the total ester content was 197.92 mg/L, the total alcohol content was 115.34 mg/L, and the content of acids, phenols, and other substances was 65.37 mg/L. There were significant differences in the contents of volatile flavor substances among different yeast strains.

Compared with the control samples, AM-MAX showed significant differences in total ester content and total alcohol content from the others, featuring high ester and low alcohol. This characteristic is consistent with its flavor profile of rich floral and fruity aromas, making it applicable to single malt whisky brewing. During the fermentation process, the AM-MAX whisky yeast produced relatively high amounts of alcohols and esters, which may be related to the wort composition and the metabolic characteristics of the yeast during fermentation. Additionally, fewer types of aldehydes and phenols were generated during fermentation, which contributes to the purity of aroma and the prominence of fruity notes, allowing the ester aroma of the yeast to be more prominently expressed.

| Published by Zhang Fangfang Senior Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com