The craft and specialty beer market is continuing to grow rapidly, with consumers increasingly demanding rich and layered flavors, a mellow and smooth mouthfeel, and diverse stylistic innovations. However, during beer brewing—especially when dealing with complex malt recipes, specialized fermentation processes, or high-gravity brewing scenarios—yeast often faces nutrient imbalances. These imbalances can lead to slow fermentation, insufficient formation of flavor compounds, and even quality risks such as off-flavor contamination. To address these challenges, we have launched BrewNutri-AZ beer yeast nutrition: an innovative product specifically designed to enhance beer fermentation efficiency and quality.

Fermentation pain points and core needs of craft beer

Insufficient yeast activity is a prevalent issue in both home and commercial brewing, often resulting in prolonged fermentation cycles, compromised flavor stability (e.g., harsh bitterness, weak aroma), and low alcohol conversion efficiency. During fermentation, yeast health is the cornerstone of brewing success—the key lies in unlocking the yeast's full performance potential and delivering high-quality, targeted nutritional support.

BrewNutri-AZ brewer's yeast nutrition: targeted solutions

Angel BrewNutri-AZ is a complete and balanced yeast nutrient formulated based on yeast autolysate. It is rich in key nutrients such as nitrogen, amino acids, minerals, and vitamins, and designed to promote yeast growth and health. It is particularly suitable for nutrient-poor environments, high-strength fermentation, and other stressful scenarios, providing yeast with sufficient organic nitrogen, free amino acids, and peptides. This not only reduces the production of off-flavors during fermentation, but also significantly improves the yeast's re-inoculation capacity, thus guaranteeing the high quality and stability of beer fermentation at the root. Whether addressing nutritional gaps in complex brewing scenarios or enhancing yeast activity to maintain fermentation consistency, BrewNutri-AZ provides precise support for yeast, helping to stabilize the brewing process and improve the quality of the finished product.

Practical application effects

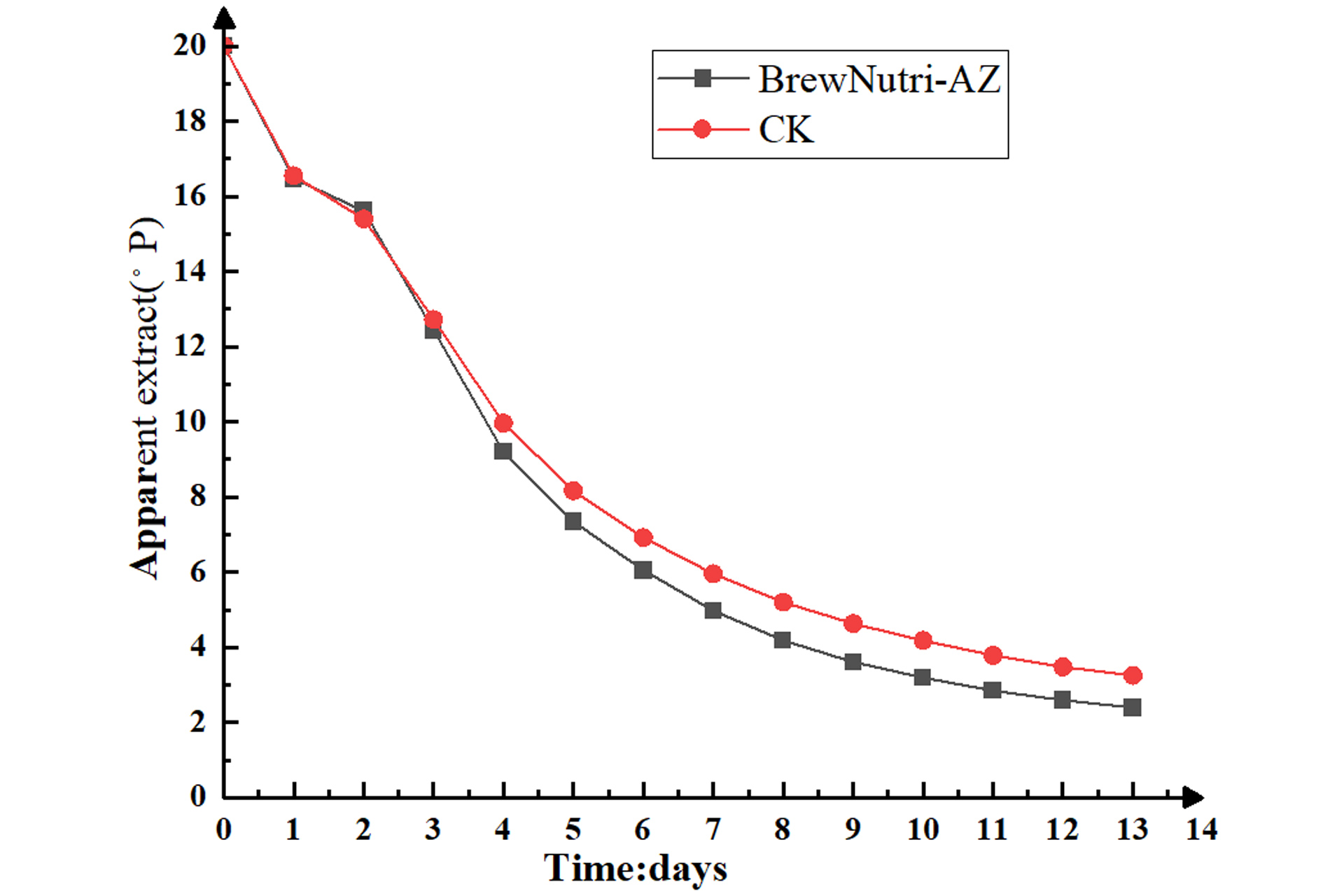

When Angel BrewNutri-AZ was applied under fermentation conditions with dry yeast (at 20°P wort concentration), it significantly increased fermentation efficiency.

Fig. 1 Changes in Wort Sugar Levels During Dry Yeast Fermentation

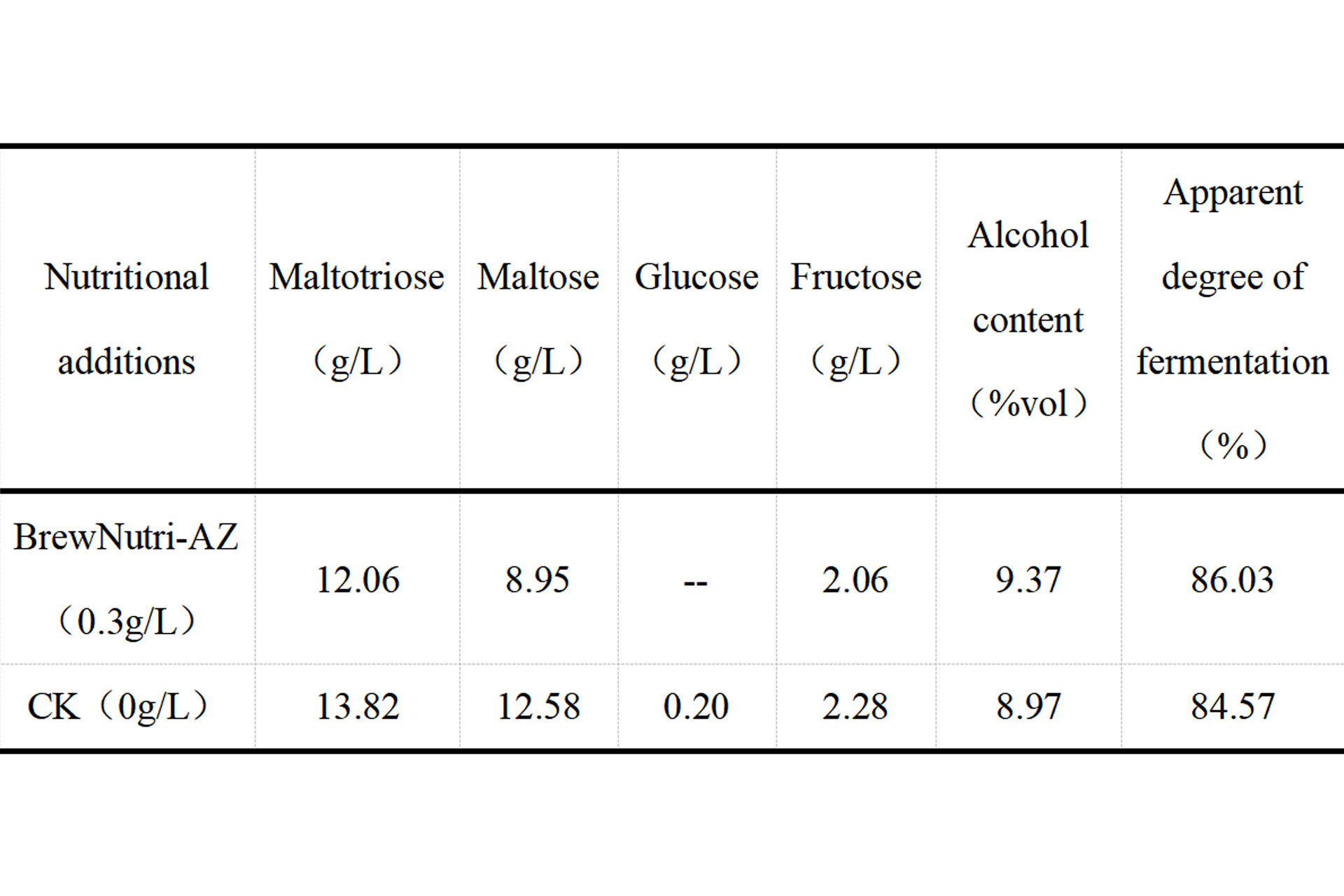

Table 1 Measurement of Indices for Dry Yeast-Fermented Beer Samples

BrewNutri-AZ: 0.3 g/L

Original gravity: 20°P

Fermentation temperature: 20℃

Dry yeast dosage: 0.2g/L

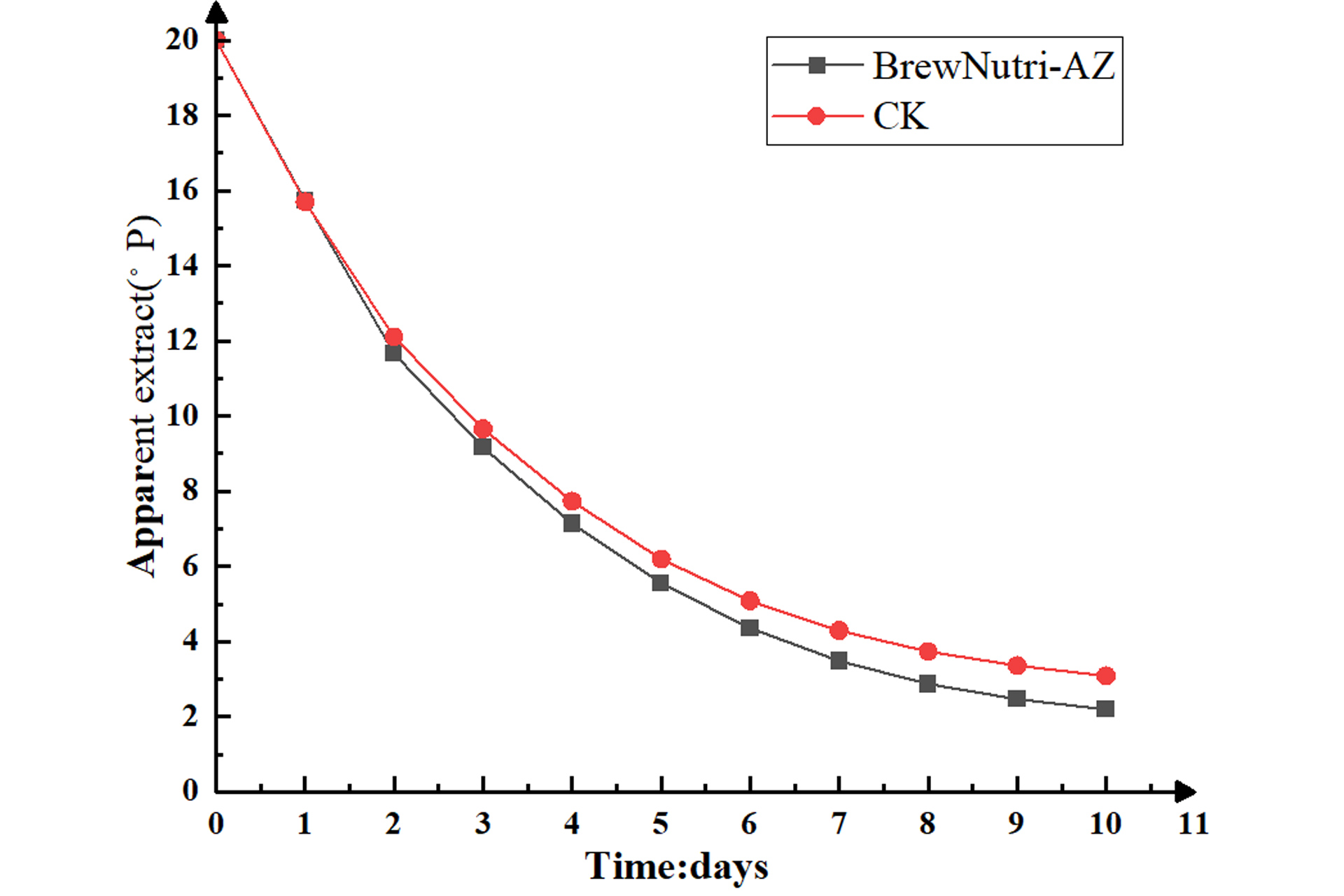

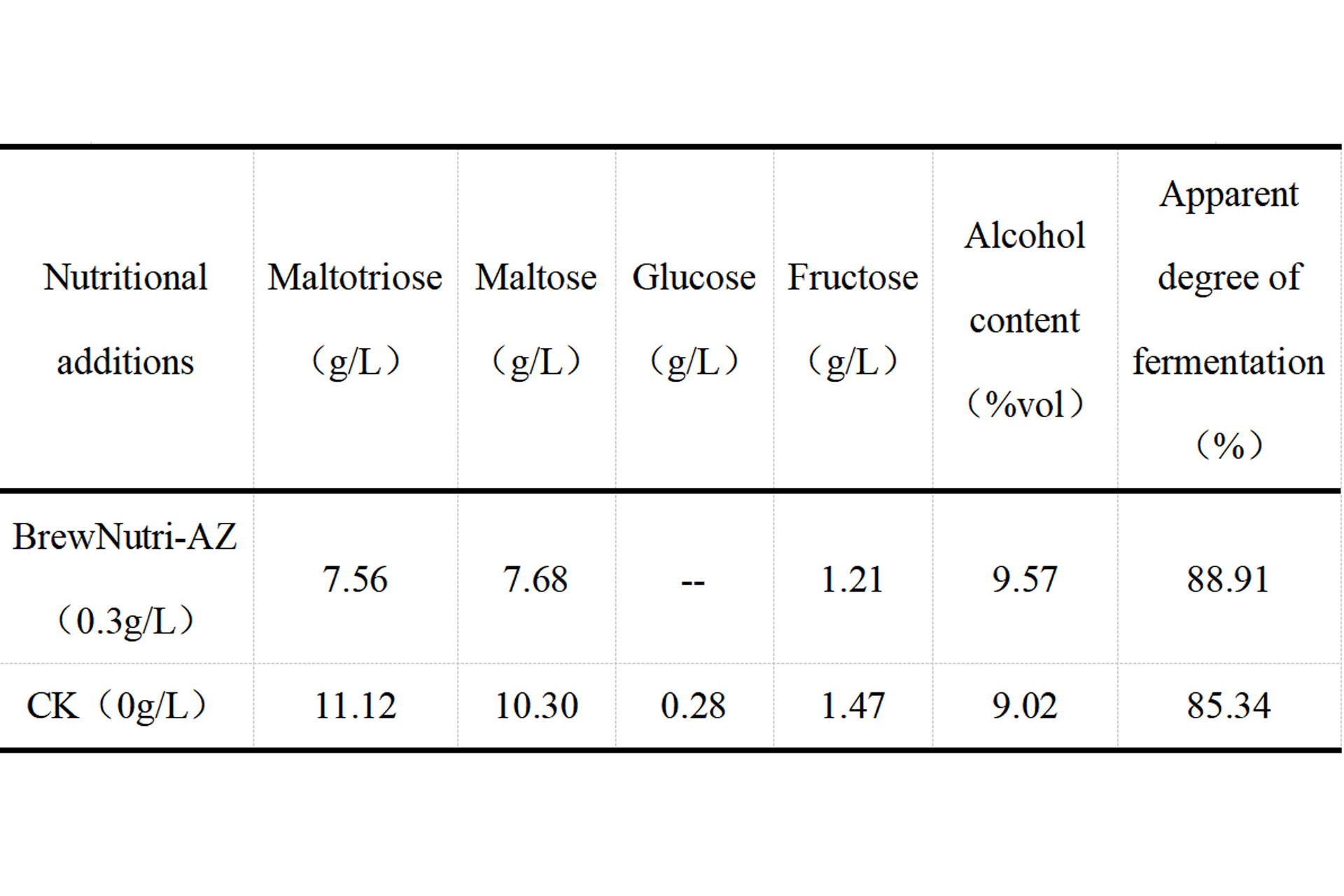

When BrewNutri-AZ is applied to yeast slurry in wort with an original gravity of 20°P, it can significantly improve the fermentation efficiency of the yeast slurry.

Fig. 2 Changes in Sugar Content During Fermentation of Yeast Slurry

Table 2 Determination of Indicators for Beer Samples Fermented by Yeast Slurry

BrewNutri-AZ: 0.3 g/L

Original gravity: 20°P

Fermentation temperature: 20℃

Yeast slurry inoculum size: 1.0×107CFU/mL

Angel BrewNutri-AZ, with its scientific innovation and superior efficacy, provides precise nutrition for yeast, ensuring stable and efficient brewing operations. It is the ideal choice for brewers seeking high-quality beer to achieve a worry-free and outstanding brewing experience.

| Published by Jia Ketao Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel Brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com