Common Raw Materials for Bioethanol

The raw materials for bioethanol production primarily fall into three categories: starch-based crops such as corn, wheat, cassava, and sweet potatoes; sugar-based crops such as sugar beets and sugarcane; and lignocellulosic materials primarily composed of straw.

Currently, lignocellulosic feedstocks face challenges due to their dense structure and complex composition, particularly in terms of pretreatment processes, expensive enzymes, and co-fermentation strains, limiting their widespread adoption. Starch-based ethanol, meanwhile, faces issues of competing with food crops for land and resources, and compared to sugar-based feedstocks, it requires factories to be equipped with liquefaction and saccharification equipment, increasing operational costs. Sugar-based raw materials do not require complex pretreatment processes and offer significant advantages in terms of equipment, production processes, and costs when used to produce ethanol.

Sugar-based raw materials are widely distributed. In low-latitude regions, sugarcane is the primary source, extensively cultivated in Brazil, China, India, and Southeast Asian countries. In mid-latitude areas, the main sources are cold-tolerant and drought-resistant sugar beets and sweet sorghum. Ultimately, they are used in the form of raw materials such as sugarcane juice, sucrose solution, and starch-hydrolyzed sugar for brewing.

The Dilemma of Sugar-based Raw Material Fermentation

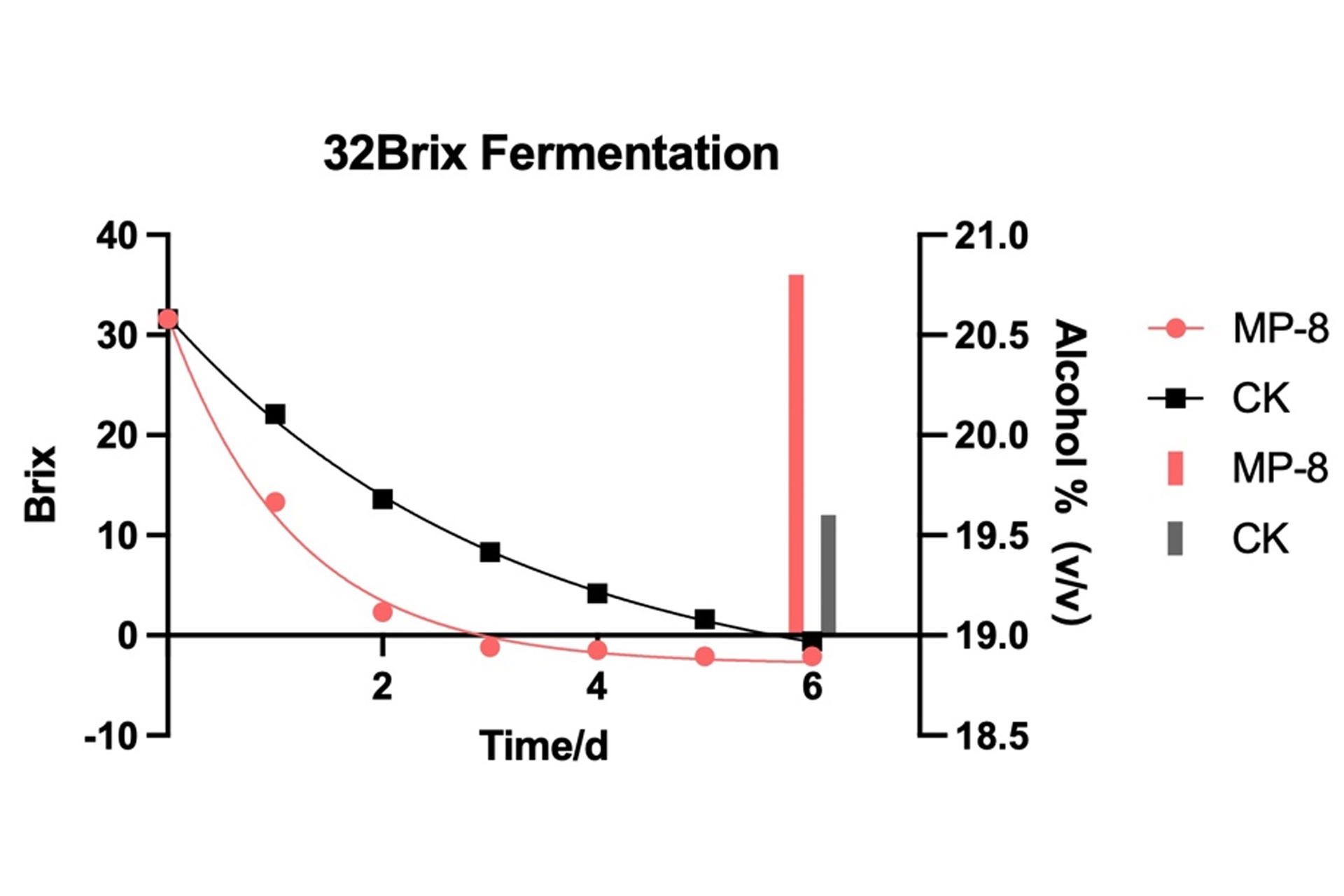

During fermentation, high-density fermentation liquid has a higher osmotic pressure, which inhibits yeast fermentation, resulting in incomplete fermentation, high residual sugar content, and frequent occurrences of prolonged fermentation times. Low-density fermentation wastes fermentation space and leads to unnecessary process water and energy consumption. Therefore, the yeast suitable for high-concentration sugar fermentation is currently a bottleneck limiting production efficiency, and there is an urgent need for high-performance yeast to improve fermentation efficiency.

Angel Yeast Comprehensive Solution: Saccharomyces cerevisiae MP-8

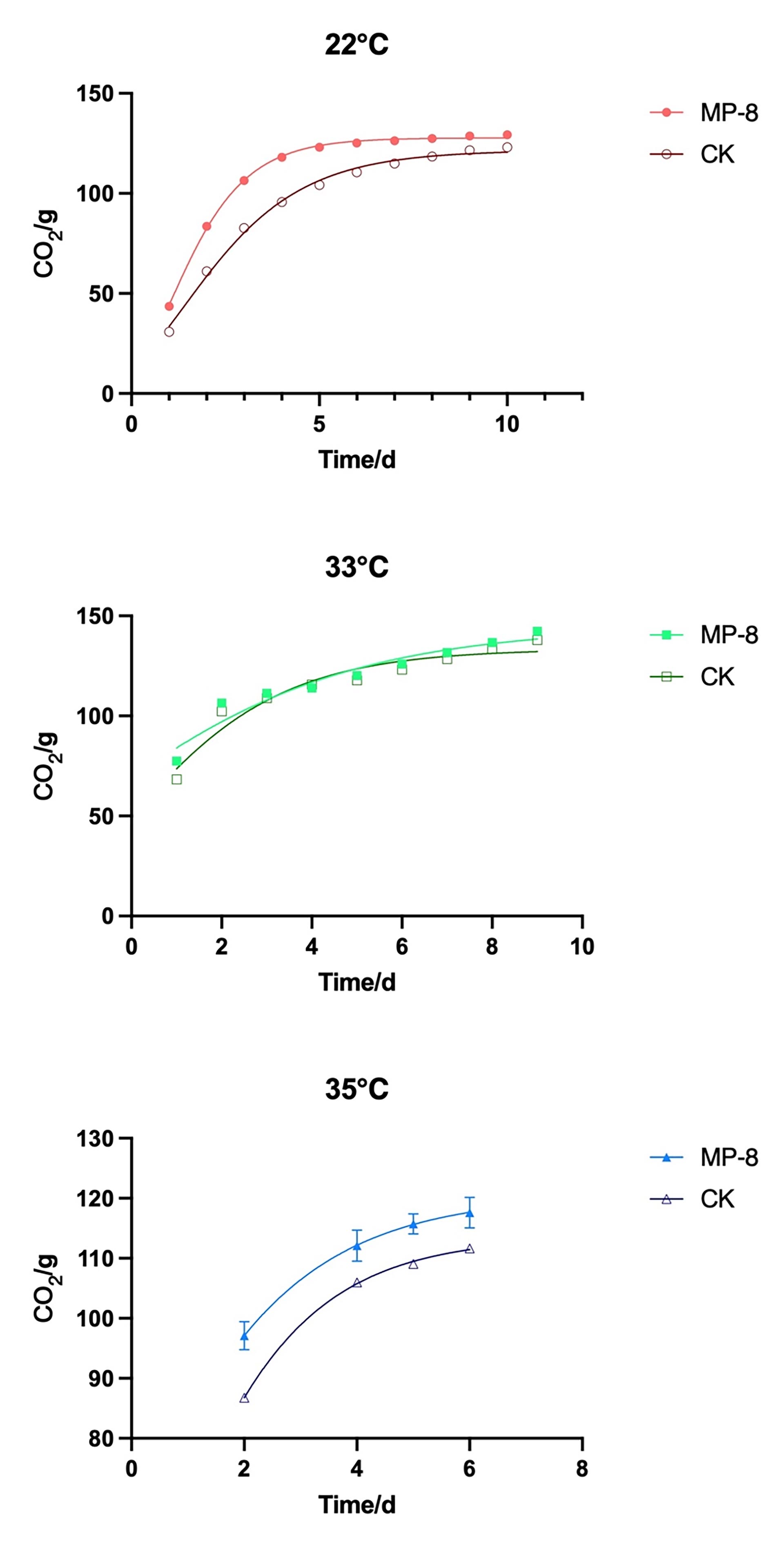

S. cerevisiae MP-8 is a new type of sugar-fermenting yeast developed by Angel through non-GMO breeding methods, suitable for producing edible alcohol and fuel ethanol. MP-8's fermentation capability covers a broader temperature range, enabling rapid metabolism of high-density sugar-based raw materials to produce high-concentration alcohol, thereby reducing material consumption in factories and improving production efficiency.

In a high specific gravity environment, MP-8 can ferment quickly and metabolize to produce ethanol, ultimately increasing yield.

Figure 1 High specific gravity fermentation comparison

The MP-8 can ferment quickly at different temperatures, has a wider temperature adaptability, and utilizes raw materials more thoroughly.

Figure 2 Better performance at various temperatures

| Published by Yang Zhenhua Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel Brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com