Aug 25th, 2020

By Andrew Lee

The application of active dry wine yeast to wine alcohol fermentation has become an indispensable part of modern winemaking process. Active dry yeast usually needs to be reactivated before use and then added to grape juice/must for alcohol fermentation. So, can active dry yeast be directly added to grape juice/must for alcohol fermentation? What is the difference between reactivation and direct inoculation?

1. what is active dry yeast

In order to make the yeast transport and store easily, the yeast cells are dehydrated and dried during the production process. Most of the final active dry yeasts have a water content of 4. 0% to 8. 0%, while the normal yeast cells have about 70% moisture content. In the drying and dehydration process of yeast production, a variety of physical and biological engineering technologies are used to make yeast cells lose all free water and most of the bound water. The lack of water causes the loss of the cell membrane hydration layer, which in turn loses normal metabolic functions and growth capacity. Therefore, there are big difference between the cells of active dry yeast and normal yeast cells (Table 1).

*Table 1. Difference in characteristics between active dry yeast and wet yeast

Wet yeast | Characteristics | Active dry yeast |

Mostly opaque or liquid | Shape | Round particles or rods |

Fresh and active | Physiological state | Shrinkage and dormancy |

>60% | Moisture content | <8% |

Free water | Water form | Bound water |

>200 | Viable count (Million /g) | >100 |

>90% | Living cell rate | >70% |

Days - months | Shelf life | 3-6 years |

2. The effect of rehydration and reactivation of active dry yeast

Before the active dry yeast is inoculated, fermented, or reproduced and metabolized, it must absorb a large amount of water to restore the yeast cells to their original natural water content at first, this is called rehydration. After rehydration, the yeast cells undergo adaptive culture for a certain period of time to restore the normal physiological metabolic functions that yeast cells should have in their natural state, and this is called reactivation. Due to the loss of the yeast cell membrane hydration layer, the disorder of the yeast cell membrane phospholipid bilayer is caused, the permeability of the cell membrane will also increase, and the selective permeability will be lost too. Therefore, the process of rehydration and reactivation of active dry yeast will be accompanied by intracellular inorganic a large amount of osmotic loss of compounds like amino acids, nucleotides, esters and other biologically active substances, especially in low temperature(Table. 2) or high osmotic pressure environments, the loss of such cell contents will be more serious, which will directly affect the yeast cells’ activity.

*Table 2. Leakage of solids of active dry yeast at different temperatures (mg/g)

Composition | Rehydration temperature(4. 3℃) | Rehydration temperature(43. 0℃) |

Ash | 27. 3 | 8. 1 |

Total nitrogen | 9. 98 | 3. 06 |

Carbohydrate | 164 | 35 |

Phosphorus | 1. 8 | 0.54 |

Amino acid | 6. 57 | 2. 19 |

Niacin | 0.238 | 0.053 |

3. What is the difference between inoculation of activated dry yeast after rehydration and direct inoculation in the alcohol fermentation process?

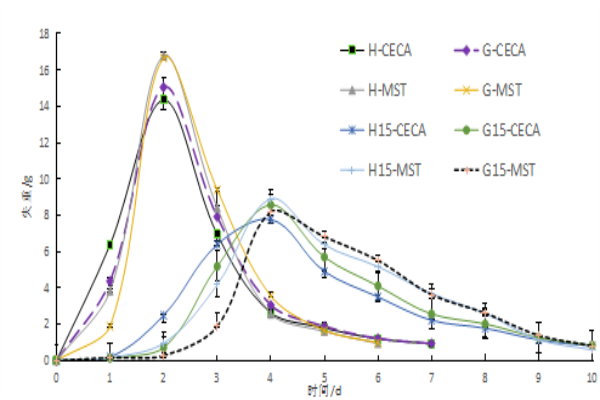

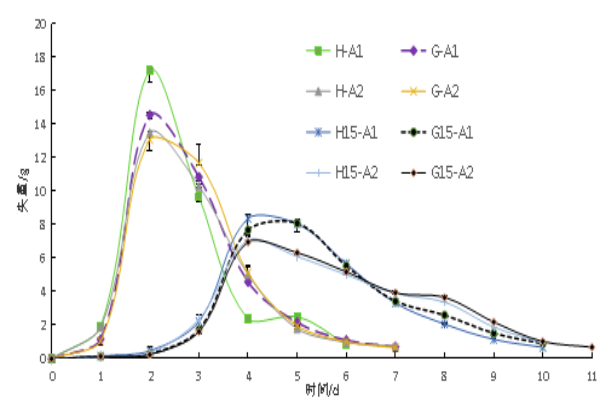

Through our research(fig. 1), we can see that, whether at 25℃ or 15℃ fermentation conditions, direct investment process will obviously cause slow fermentation speed and lag. Studies have shown that rehydration of active dry yeast at a temperature between 35 and 43℃ helps the cell membrane change back to a liquid crystal state and minimizes content leakage. Therefore, winemakers usually choose 35~ 38 ℃ to rehydrate, and then add with some grape juice to reactive, or directly reactivate with 4% ~ 5% sugar solution before active dry wine yeast inoculating. If the rehydration temperature is lower than 30℃, the viability loss of the yeast cells will be more serious, especially the active dry yeast without added protective agent will be more damaged. However, active dry yeast that has not been rehydrated and reactivated directly puts into grape juice/must, and faces adverse conditions such as low temperature and high osmotic pressure, and the loss of yeast cell contents will be more serious. The large loss of yeast activity is one of the reasons why the inoculation of active dry yeast after activation is faster than that of direct inoculation, and under the direct injection process at 15 ℃, it is easy to cause the potential risk of slow and incomplete sugar reduction in the late fermentation period and prolonged fermentation cycle.

Fig. 1 Single-day weight loss(CO2) fermentation curve of four kinds of active dry yeast CECA, MST, A1, and A2 fermentation. “H-” and “G-” represent “reactivated” and “direct inoculation” processes under 25 ℃ fermentation conditions, and “H15-” and “G15-” represent “reactivated” and “direct inoculation” processes under 15 ℃ fermentation conditions.

4. How to activate active dry wine yeast?

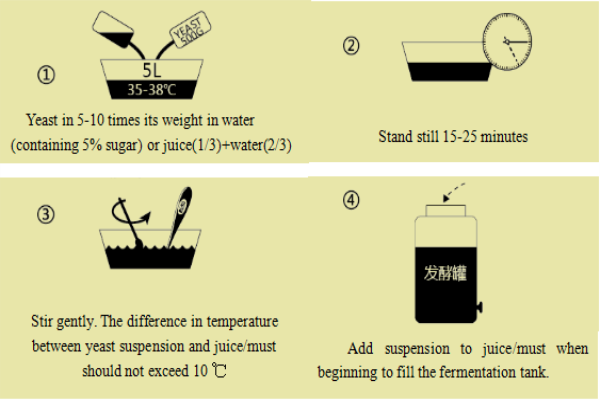

In order to ensure the smooth fermentation process of your alcohol fermentation, before inoculating the active dry wine yeast into grape juice/must you can activate it as follows.

Angel Yeast Company has a wide range of active dry wine yeast. After proper activation of the Angel active dry wine yeast, the Saccharomyces cerevisiae can quickly occupy a dominant position after being inoculated into grape juice or must, and quickly start alcohol fermentation to avoid miscellaneous bacteria pollution.

Angel Yeast Company is an important supplier of wine yeast, yeast derivates and yeast nutrients in the world, providing natural, safe, and of high quality products and technical solution, helping customers optimized fermentation process, improve wine quality.

About Distilled Spirits and

Biofuels Division:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

| Published by Andrew Lee Application engineer Enologist Angel Distilled spirits and Biofuels Division |

For more media information, please contact:

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: wusy@angelyeast.com

en.angelyeast.com