Published by Can Yu, edited by George Hu.

22th December, 2023.

The malolactic fermentation(MLF)in wine is a fermentation process led by lactic acid bacteria after alcohol fermentation(AF), also known as secondary fermentation. In the process of MLF, lactic acid bacteria, under the action of malic acid lactase, use L-malic acid as the substrate to generate L-lactic acid and carbon dioxide. Spontaneous malolactic fermentation is usually uncontrollable, and harsh environments such as low pH, high alcohol concentration, high SO2 concentration, and low temperature in wine can hinder the growth of lactic acid bacteria, ultimately leading to the forced suspension of fermentation. At present, the lactic acid bacteria that can start malic acid lactic acid fermentation include four genera, namely, Pediococcus, Leuconostoc, Oenococcus oeni and Lactobacillus. Among them, Oenococcus oeni and Lactobacillus plantarum can overcome the harsh wine environment and are widely used in food science technology and fermentation products.

At present, the most widely used malic acid lactic acid starter in the domestic wine market is Oenococcus oeni. However, Oenococcus oeni fermentation has problems such as long fermentation time, high energy consumption, and low pH, insufficient nutrition, and high concentration of ethanol can inhibit bacterial growth. Only when the concentration is >1×108 CFU/mL, and only when domesticated at a sublethal alcohol concentration can malate lactic acid fermentation be initiated and completed; Lactobacillus plantarum can function well under low pH conditions, with a tolerance to ethanol of up to 14%, similar to that of Oenococcus oeni, and has more diverse enzyme activity, which can produce more aromatic compounds, all of which help Lactobacillus plantarum become the latest generation of wine MLF starter.

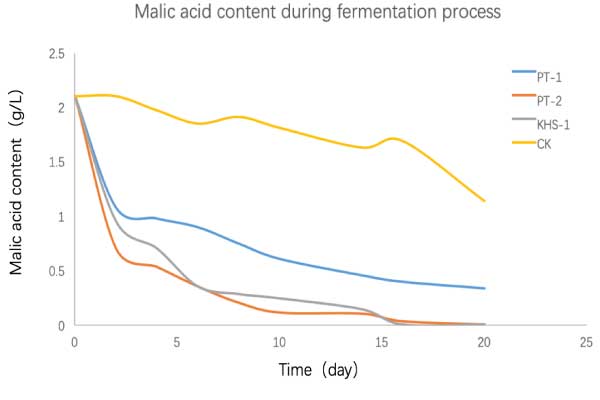

Assessed by application experime, We have developed Lactobacillus plantarum PT-2. It can efficiently utilize malic acid and convert it into lactic acid. And it can reduce the malic acid content to a very low concentration in a short period of time. We used two other strains of Lactobacillus plantarum as a comparison. The results are shown in the following figure. PT-2 exhibits MLF capability no less than KHS-1. PT-2 also has some special flavour substances in wine brewing, and bringing a joyful feeling to the taster.

(CK: Inoculate without lactic acid bacteria;KHS-1:Christian Hansen SmartBev Harvest LB-1)

About Angel Fermented Beverages

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Distilled Spirits and Biofuels Division

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, whisky, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

For more media information, please contact

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com

en.angelyeast.com