Mar. 5, 2021

By Andrew Lee

The application of non-Saccharomyces cerevisiae in wine has increasingly become a new trend. Relying on the rich and diverse specificity of non-Saccharomyces cerevisiae can bring various improvements to the quality of wine in a targeted manner, including improving aroma and regulating main metabolites. Biological prevention and control, etc. Kluyveromyces thermotolerans is a kind of non-Saccharomyces cerevisiae that aims to solve the problem of low total acid and high pH in wine.

For warm viny region, winemakers always encounter the problem of too low total acidity of must during the grape harvest season each year. The choice of sugar, acid, and tannins is a problem that makes many winemakers entangled. Since the warm viny region has sufficient sunlight, the grape fruits receive sufficient sunlight and heat during the growing season. The total sugar and total phenols in the grape skin accumulate quickly, but the grape seeds mature relatively slowly, and the grape seeds are immature. Contains a lot of inferior tannins, which brings dryness and bitterness to the wine, which seriously affects the quality of the wine.

Therefore, the choice of most winemakers is to postpone the harvest, but the problem comes again. The grape harvested late are often high in sugar, but the total acid content is obviously insufficient, and the pH is also too high.

The total acid content and pH of must and wine have an impact on all aspects of wine, including the ability to resist contamination by bacteria, the solubility of tartaric acid, the effect of using sulfur dioxide, the polymerization of pigments and oxidation and browning reactions, and the activity of enzymes, protein solubility, wine aging potential, taste, etc.

Under ideal conditions, the total acid in wine is 6. 5-8. 5g/L (calculated as tartaric acid), and the ideal pH for table wine is 3. 0-3. 3. For must with low acidity, acidity adjustment is required to achieve the best total acid and pH state. The usual method is to add tartaric acid. Tartaric acid is the most important organic acid in wine, and tartaric acid is not easily utilized by microorganisms.

Tartaric acid and potassium ions in wine form potassium hydrogen tartrate, and potassium hydrogen tartrate is not easily soluble in alcohol. As alcohol fermentation progresses, the solubility of potassium hydrogen tartrate in wine will continue to decrease, forming a precipitate attached to the tank wall, resulting in the total acid is reduced, so it sometimes appears that although enough tartaric acid is added before the alcohol fermentation starts, the total acid still does not reach the required level after the alcohol fermentation ends. Moreover, adding a large amount of tartaric acid will greatly increase the brewing cost.

Organic acids in wine

organic acids | Content g/L |

tartaric acid | 5-10 |

malic acid | 2-4 |

citric acid | 0.04-0.7 |

lactic acid | 0-2. 5 |

succinic acid | 0.5-1. 5 |

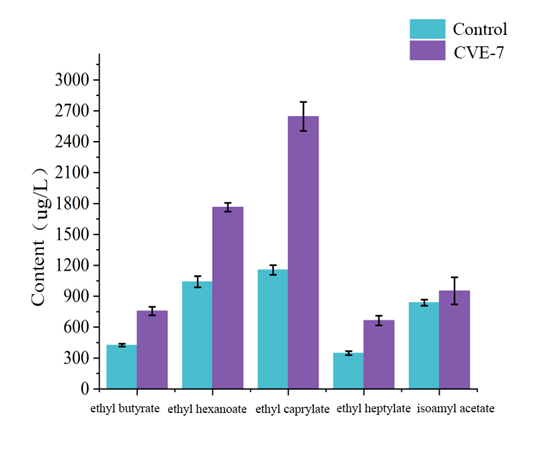

Angel Yeast Co., Ltd. and the scientific research team of the Grape and Wine Research Center of China Agricultural University have screened out a strain of Kluyveromyces thermotolerans CVE-7 with excellent fermentation performance. This yeast can convert part of sugar into lactic acid, thereby increasing the total acid content of the wine, lowering the pH of the wine, and enhancing the aroma of the grapes, giving the wine the aroma of tropical fruits such as grapefruit, pineapple, and mango.

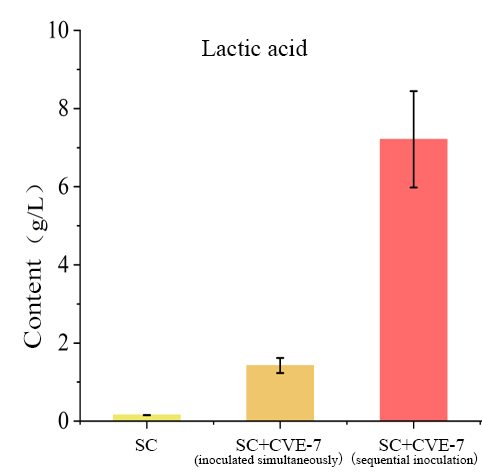

In order to ensure the smooth progress of alcohol fermentation, the complete fermentation of residual sugar, and the ability to produce enough lactic acid to increase the total acid content and lower the pH, the combination of Saccharomyces cerevisiae and Kluyveromyces thermotolerans has the best effect. You can choose co-inoculation or sequential inoculation according to the total acid content of the must. Co-inoculation: Kluyveromyces thermotolerans CVE-7 and Saccharomyces cerevisiae were simultaneously inoculated into must at a ratio of 1:1 for alcohol fermentation. Sequential inoculation: first inoculate 15-40g/100hL CVE-7 for alcohol fermentation for 10-48h, and then inoculate 15-40g/100hL Saccharomyces cerevisiae. This inoculation method produces higher lactic acid content than co-inoculation.

The use of CVE-7 and Saccharomyces cerevisiae co-inoculation or sequential inoculation can significantly increase the total acid content in wine, the acid increase range is 3-7g/L, the pH drop range is 0.2-0.5, and the flower and fruit aroma of wine can be increased at the same time, and also stabilize the color of wine.

About Distilled Spirits and Biofuels Division:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

| Published by Andrew Lee Application engineer Enologist Angel Distilled spirits and Biofuels Division |

For more information, please contact:

Ryan Wu

Angel Yeast Co., Ltd.

Tel.: +86 717 6353619

Email: wusy@angelyeast.com

en.angelyeast.com