Published by Xun Chang, edited by George Hu.

27th September 2023.

Active dry yeast, which is increasingly used in the brewing industry, needs to be rehydrated before being inoculated into the fermentation mash. When active dry yeast with a very low water content is suddenly mixed with water, the nutrients in the yeast cells will permeate outside the cells, especially when rehydrated in cold water, and the result will inevitably affect the physiological function of the rehydrated cells. Therefore, choosing the right conditions for yeast rehydration can effectively improve the activity of yeast.

In order to facilitate storage and transportation, commercial yeast cells are dehydrated and dried during the yeast production process, resulting in active dry yeast with a moisture content of mostly 4.0-8.0%, whereas the moisture content of normal yeast cells in their natural state is mostly around 70.0%. In the drying and dehydration stage of yeast production, the loss of water leads to the loss of the hydrated layer of the cell membrane, which in turn leads to the loss of normal metabolic and growth functions.

Therefore, before active dry yeast is inoculated for fermentation or reproduction and metabolism, it must first absorb a large amount of water to restore the yeast cells to their original natural state of water content, which is called rehydration, or rehydration. After rehydration, the yeast cells then undergo a certain period of adaptive cultivation and return to the normal physiological and metabolic functions that yeast cells in their natural state should have, which is known as activation.

The rehydration of active dry yeast and its activation method are very important for the physiological function of the cells after rehydration. Studies have shown that the rehydration temperature of active dry yeast is generally chosen to be between 30-40 °C and the time is generally controlled to be 40-60 min. The common rehydration and activation solutions for dry yeast are tap water, sugar water, dilute saccharified mash and activation nutrients. Tap water as yeast activation solution, in addition to providing a liquid environment for yeast rehydration,there are no other nutrients available for yeast growth, and the yeast after activation is in poor condition and fermentation is poor.

Using sugar water rehydration activation, although there is sugar available to the yeast, the yeast does not start fermenting quickly and does not produce as much wine due to the lack of other nutrients. Activated nutrients are nutrients that are beneficial to yeast cell growth. Using activated nutrient rehydrated yeast enhances cell membrane fluidity, ensures cell membrane integrity, low cell death rate, high germination rate and rapid fermentation.

Angle has developed a rehydrated nutrition called Nutri-rehyd. Nutri-rehyd is a pecific yeast nutrient for dry yeast rehydration to provide organic nitrogen, essential vitamins, minerals, and survival factor (unsaturated fatty acid ergosterol), avoid fermentation problems, such as sluggish and stuck fermentations and reduce the production of off-flavours.

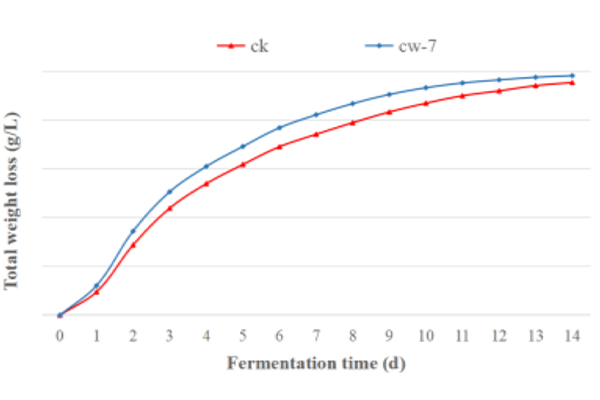

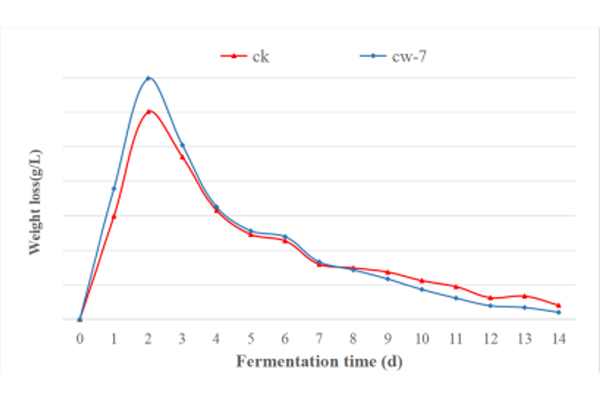

Yeast fermentation curves under different rehydration conditions (Cabernet Sauvignon grapes with a sugar content of 250 g/L were used and fermented at 25 °C. CK is not added nutrition of yeast rehydration.)

| Published by Xu Chang Director of Distilled Spirits and Biofuels Division |

About Angel Fermented Beverages:

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Distilled Spirits and Biofuels Division:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, whisky, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

For more media information, please contact:

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com

en.angelyeast.com