Bioethanol, a renewable energy source derived from biomass such as sugars, starch, or cellulose, is widely used in transportation fuels and chemical industries. Its closed carbon cycle reduces greenhouse gases by 60% compared to gasoline while cutting tailpipe pollutants by 50%.

In bioethanol production, the process is frequently hindered by inhibitors such as acetic acid, lactic acid, furfural, and 5-hydroxymethylfurfural (HMF). These substances inhibit yeast growth, impair alcohol fermentation, and ultimately lead to incomplete fermentation and reduced ethanol yield. To address these challenges, Angel Yeast Company has developed a superior yeast strain through mutagenesis and high-throughput screening techniques——Angel Alcohol Active Dry Yeast TR——exhibiting enhanced inhibitor tolerance.

Acetic Acid Resistance

Acetic acid, primarily produced by Acetobacter during lignocellulose pretreatment through complete hydrolysis of acetylated hemicellulose, exerts multiple effects on yeast cell membranes. While low concentrations minimally impact membrane composition(studies show yeast can activate stress-response mechanisms under mild acetic acid conditions), high concentrations critically compromise membrane integrity. Additionally, elevated acetic acid levels downregulate genes associated with membrane component synthesis.

Lactic Acid Synergy

Mainly produced by lactic acid bacteria, lactic acid demonstrates weaker individual inhibition compared to acetic acid. However, its coexistence with other organic acids creates a mixed-acid system that amplifies inhibitory effects. High lactic acid concentrations alter cell membrane permeability, impede nutrient absorption, inhibit key enzymatic activity, disrupt sugar metabolism pathways, and interfere with proton gradients essential for energy metabolism.

Furan Derivatives Challenge

Lignocellulose hydrolysis generates furan inhibitors including furfural, acetic acid, and HMF:

1. 5-Hydroxymethylfurfural (HMF): Primarily derived from six-carbon sugar degradation (e.g., glucose), commonly formed during acid/alkali pretreatment.

2. Furfural: Mainly produced from five-carbon sugars (xylose, arabinose) in hemicellulose degradation. With higher thiol reactivity than HMF, furfural exhibits greater toxicity. It disrupts glycolytic and ethanol synthesis enzymes while altering membrane composition and permeability, ultimately impairing cell growth and metabolism.

TR Yeast Performance Advantages

Angel's TR yeast demonstrates exceptional tolerance to acetic acid, lactic acid, and furfural, maintaining robust ethanol fermentation even in high-inhibitor environments. This enables bioethanol plants to enhance both raw material utilization and production yields.

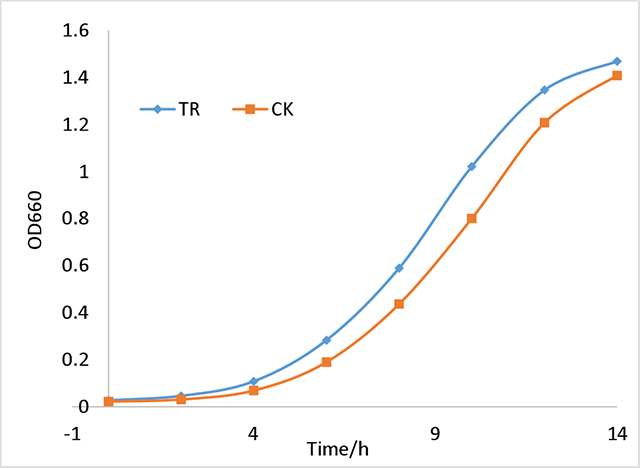

Fig.1 Yeast Growth Curve

In medium containing 2.5g/L acetic acid, TR exhibits significantly faster growth rates compared to control strains (CK).

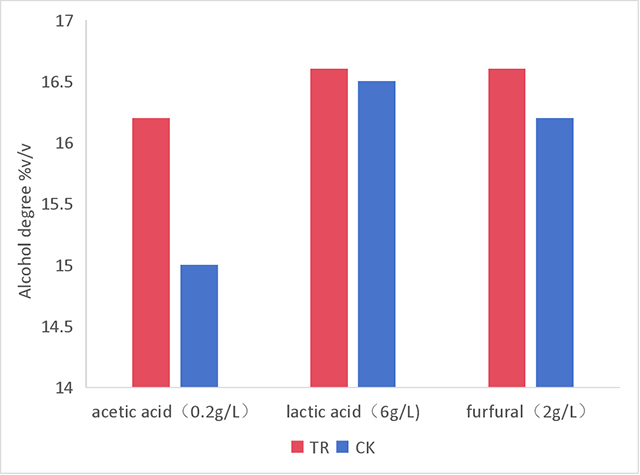

Fig.2 Fermentation Alcohol Content

TR achieves higher ethanol concentrations than CK in corn mash supplemented with acetic acid, lactic acid, or furfural individually.

| Published by Li Hui Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: brewing@angelyeast.com