Dec. 31th, 2019

By Tina Liao

With the continuous development of biotechnology, alcohol is not only an important beverage product, but also an important energy source. In the production of alcohol and fuel ethanol, the bacteria will be controlled to ensure the normal production.

In the process of ethanol production and fermentation, such as infection of bacteria, large-scale propagation of bacteria consumes a lot of sugar, and various by-products produced at the same time will inhibit the activity of yeast, eventually leading to the rancidity of fermentation mash, greatly reducing the alcohol yield, seriously affecting the normal production of alcohol.

The most common bacteria are: Acetobacter, Lactobacillus, butyric acid bacteria and Bacillus subtilis. How to control or kill the mixed bacteria in time and reduce the loss caused by the mixed bacteria becomes an urgent problem in alcohol fermentation.

At present, the common sterilization methods used in alcohol factories are:

1. The heating sterilization method regularly uses steam to carry out high-temperature sterilization of the mixing tank, liquefying tank, saccharification tank, seed tank, fermentation tank and their connecting pipes, as well as the heating sterilization of raw materials.

2. The acidification method adds a lot of sulfuric acid to the saccharification liquid, which greatly increases the acidity of the fermentation liquid, and inhibits the growth of yeast as well as the growth of bacteria.

3. Chemical sterilization

Chemical sterilization method mainly uses some chemicals to kill bacteria, which is generally used for workshop disinfection and sterilization.

4. Antibiotic sterilization

At present, penicillin and streptomycin are commonly used, but long-term use will lead to drug resistance.

Angel Yeast Company has researched and developed a yeast source bacteriostatic agent. Through the extraction of polysaccharide with bacteriostatic activity after directed enzymolysis of yeast cells, this product has broad-spectrum bacteriostatic effect, and has obvious inhibitory effect on Bacillus, Escherichia coli, acetic acid bacteria, Staphylococcus aureus, etc., and the product is safe in use without residue and drug resistance. The product is suitable for long-term use and can effectively inhibit the acid rise of fermentation system.

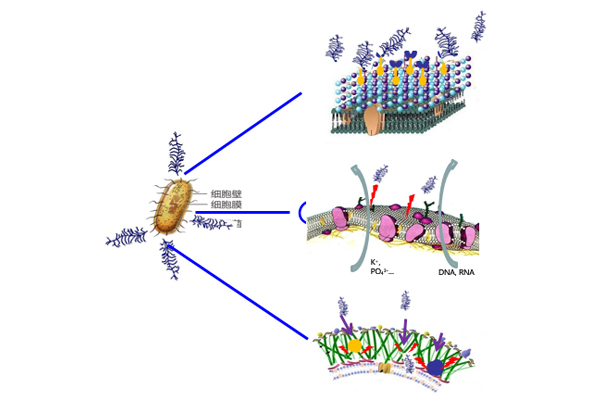

In many research reports, it can be found that polysaccharides with antibacterial effect mainly have the following functions:

1. It interferes with the normal metabolism, growth and reproduction of bacteria by glycoprotein receptor on the cell wall of bacteria

2. Destroy the cell wall or plasma membrane of bacteria, cause the damage of cell membrane, lead to the dissolution and exosmosis of intracellular substances (protein, inorganic ions, etc.) and bacterial cell death.

3. Activation of cell wall degrading enzymes (glucanase, chitinase, etc.) leads to cell wall damage and plays a bacteriostatic role.

About Angel Distilled spirits and Biofuels:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

|

Published by Tina Liao |

Press contact:

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86 717 6353619

Email: ethanol@angelyeast.com