The effect of nutrient NutrienFast adding time at different stages of wine fermentations was studied to solve or provent the problems of stuck or sluggish fermentations in grape must with high sugar and insufficient yeast assimilable nitrogen. The results show that the addition of nutrients at different fermentation stages have different effects on fermentation profile, total CO2 weight loss, final density, and alcohol content of wine. The fermentations of adding nutrient at 35% and 45% sugar consumption have more effective than other fermentations, and the fermentations finish completely. Adding nutrient after 50% suger consumption, the positive effect of nutrient added by artificiality fall into a decline. The timing of nutrient supplementation is critical for preventing sluggish or stuck fermentations and ensuring complete fermentation.

Introduction

Saccharomyces cerevisiae, the main microorganism in wine alcoholic fermentations, require a relatively high level of nutrients to complete the fermentations, typically making 13–16 % v/v ethanol or above. Yeast assimilable nitrogen (YAN) has been identified as a key nutrient to help yeast finish wine fermentation completely. The principal sources of YAN in grape must are organic nitrogen (α-amino acids and small peptides) and mineral nitrogen (ammonium).

The available nitrogen compounds are important to ensure proteins synthesis and transport of sugars into the yeast. Insufficient nitrogen in grape must leads to lower yeast biomass which increases the risk of sluggish or stuck fermentations, and can also cause the production of off-odours like hydrogen sulphide (H2S), acetic acid, and other off flavors. Nitrogen is often a limiting factor for yeast growth during alcoholic fermentation. It is therefore necessary to measure the concentration of YAN in grape must in order to balance the nutrient and satisfy the requirement of yeast growth by artificial additions.

When the YAN of grape musts is in deficiency, it is recommended to supplement juices with nitrogen nutrients during fermentation to ensure an adequate population of yeast. The purpose of this work was to assess the effect of nitrogen addition timing on alcoholic fermentations under wine-making conditions.

Materials and methods

Yeasts strains and nutrient

Angel wine yeast CECA was used in Cabernet Sauvignon grape juice (sugar 280 g/L, pH 3. 6, YAN 180ppm).

Yeast nutrient: NutrienFast, 400mg/L in different stages.

Fermentation conditions

A deficient must was selected (YAN 180 mg N/L) and sugar was adjusted to 280g/L by sucrose. Saccharomyces cerevisiae CECA (Angel, China), a yeast used by the wine industry, was employed in this study with 250 mg/L.

Fermentation was performed in 500 ml flasks, containing 500 ml grape juice with an airlock system to maintain anaerobiosis at 25 °C. Fermentation was monitored by CO2 release: the amount of CO2 released was determined by measuring weight loss one time per day. Additions were performed at the stage of 0%, 10%, 25%, 35%, 45%, 55%, 60%, 68%, 74% sugar consumption with different densities 1118,1107, 1090, 1078, 1070, 1057, 1053, 1044, 1039, respectively. All fermentations were performed in duplicate.

Results and discussion

Nitrogen composition and concentration of grape musts affects the growth and metabolism of yeast, the fermentation rate, and the completion of fermentations. Nitrogen deficiencies in grape must are one of the main causes of stuck or sluggish wine fermentations. In this study, we supplemented nitrogen-deficient fermentations with NutrienFast at different stages throughout wine fermentations.

NutrienFast is a blended complex yeast nutrient with two different sources of nitrogen: mineral source as di-ammonium phosphate (DAP) and organic source coming from inactive dry yeast. Inactive dry yeast is widely used in wines to improve fermentation and wine organoleptic characteristics. NutrienFast supplies ammonium, amino acids, vitamins, sterols and long chain fatty acids to promote yeast metabolism and prevent the production of undesirable compounds.

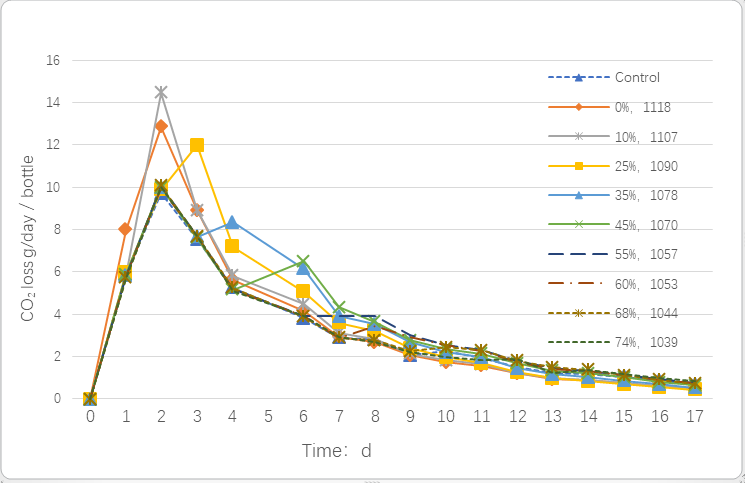

Fig. 1 The effect of NutrienFast on wine fermetation kinetics

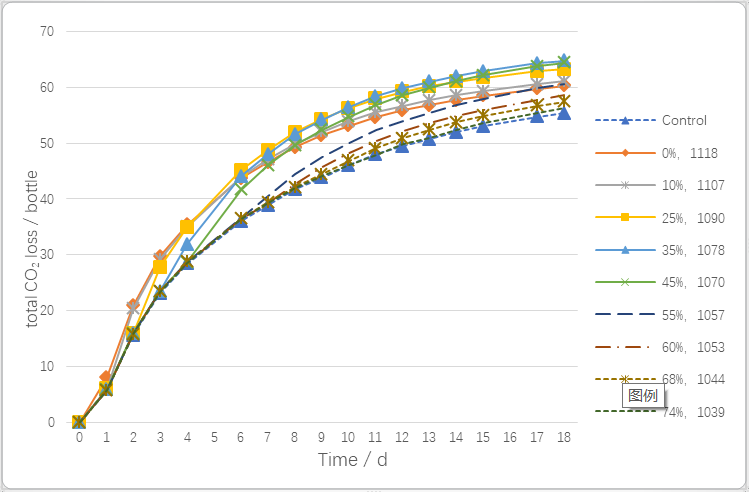

Fig. 2 The effect of NutrienFast on total CO2 loss

We investigated the impact of the addition timing of 400 mg/L NutrienFast at different stages on the fermentation kinetics, final density and ethanol. The CO2 loss were monitored every day. Nitrogen additions at different stages have different wine fermentation profiles and final results. Fig. 1 shows the effect of nitrogen additions on fermetation kinetics.

As expected, NutrienFast addition at the early stage of fermentations (0%, 15%, 25%) led to an increase of the maximal CO2 production rate (Fig 1), but the total CO2 loss is not the most (Fig 2). In this study, the trials performed 18 days, only two of them, adding nutrient at 35% and 45%, completed the fermentation (the sugar<2g/L). The consequences of nutrient addition during the medium phase (35 and 45%) were very different from the others of the early and late stage addition to the must. The total CO2 loss of 35% and 45% is up to 64. 81g/bottle and 64. 41g/bottle respectively, and the sugar of all of those fermentations were exhausted. Additions after 50% sugar consumption have less effect on the fermentation rate. When nitrogen was added after the half of the fermentation, the effect of nitrogen on wine fermentation was not significant. The fermentation adding nutrient at 74% has similar fermentation rate with the control fermentation without adding nutrient.

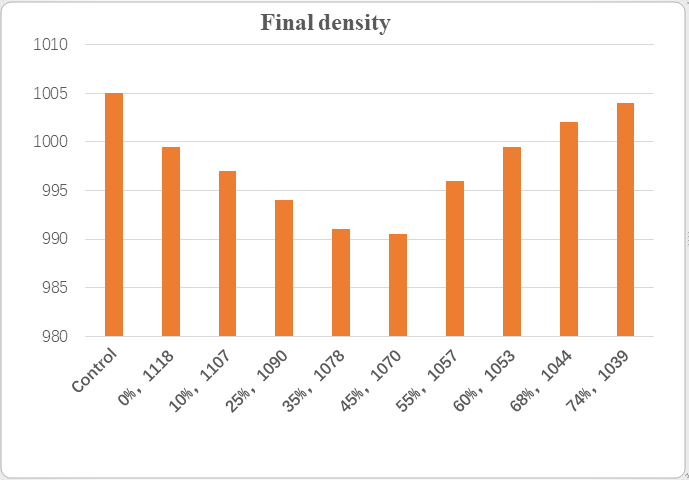

Fig. 3 Effect of nutrient addition on the final density of wine

Not all the sugars in different fermentations were exhausted at the end of all of the fermentations. Fig. 3 shows the effect of nutrient addition on the final density of wine. Additions at 35% and 45% sugar consumption had maximal effects on density decrease. The final densities of the both comentations are lower than the others, which are 991 and 990.5, respectively. The final density shows the process of fermentation, the more thorough the fermentation, the lower the specific gravity. When nitrient is added in the later stages of the fermentation, it is hardly consumed. After 50% sugar consumption, the effect of nutrient on fermentation was weakened with the delay of adding time. The final density of the control fermentation without adding any nutrient is 1005, so it is stuck.

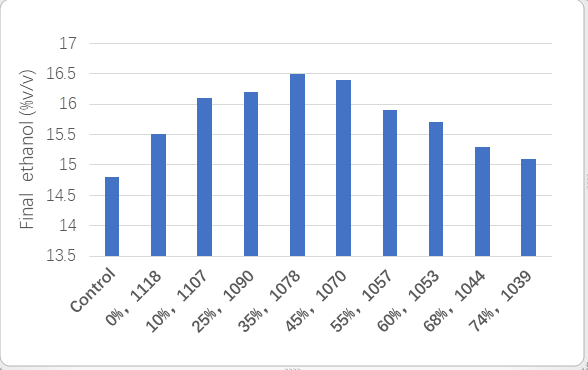

Fig. 4 Effect of nutrient addition on the final ethanol of wine

The change trend of final ethanol content in different fermentations was opposite to that of specific gravity (Fig.4). The final ethanol of 35% and 45% nitrient addition is higher than other fermentations (Fig. 4). Final concentrations of ethanol were different for all the conditions. The timing of NutrienFast additions influenced the fermentation kinetics, the final density, and ethanol. Adding time of nutrient during fermentation is critical to increases yeast growth and stimulates the rate of sugar utilization.

Conclusion

The addition of nitrogen to grape must is a common winemaking practice that prevents sluggish or stuck fermentation problems and optimizes fermentation performance. In this study, we supplemented a nitrogen-deficient grape juice with a complex nutrient NutrienFast at different stages of the alcoholic fermentation. We studied the effect of these additions on the fermentation profiles, the final density and ethanol. Adding nutrient of NutrienFast at different stages has different fermentation profiles and the final density and ethanol. In our study, the results have important implications for wine fermentation, because it highlights the value of determining the time of nutrient supplementation. The timing of nutrient supplementation is critical for ensuring completely fermentation and preventing sluggish and stuck fermentations. Nutrient supplementation at 35% and 45% of the sugar consumption was proved to be a highly effect on alcoholic fermentaion. In addition to improve yeast growth, nitrogen nutrient can also affect many aspects of yeast metabolism, including the formation of volatile compounds that are important for the organoleptic qualities of wine.

| Published by Fang Fang |

About Angel Distilled spirits and Biofuels:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86 717 6353619

Email: ethanol@angelyeast.com