By Fangfang Zhang

August 24, 2022

Yeast is fundamental in beer brewing, which needs a lot kinds of nutrients to have a good fermentation profile. Problems during beer fermentation not only need long time to ferment but it leads to lower the beer quality. There are different reasons for problem fermentation, such as lack of nitrogen, lack of oxygen and lack of mineral, especially zinc. Although there are enough nitrogen nutrients in wort, zinc is not enough in wort for yeast growth, and the lack of zinc will lead to the risk of bad flavor in beer. Zinc affects yeast growth, sugar transport, alcoholic fermentation and the yeast viability and floculation at the end of fermentation. Brewer need to check the concentration of zinc before starting the fermentation.

Zinc is one of important minerals that is often limited in wort. It was found that concentration of zinc gradually decreases during production of wort. Zinc left in wort is only a fraction form malt and most zinc remains in the used malt or is lost during protein precipitation and wort clarification. The lack of zinc in the wort leads yeast in bad healthy and take maltose slow. Optimum zinc levels in wort stimulates the metabolization of yeast.

Why is zinc so important in beer brewing?

Zinc is an important co-factor in yeast growth and alcoholic fermentation. Most yeast strains require 0.3-0.5 mg/L of zinc. Zinc may be the only deficiency yeast nutrient even in all-malt wort. Adding zinc generally effect on fermentation rate, as well as preventing stuck fermentations. Zinc rapid uptakes by yeast in the first hours of fermentation and accumulates in the vacuole.

In bad fermentation condition or in zinc-lack wort, the acetaldehyde, diacetyl and sulphur compounds are the common off-flavor. Acetaldehyde, diacetyl and sulphur compounds are the commonly off-flavor in bad healthy fermentation.

(1) Healthier yeast makes better beer.

The lack of zinc will last the fermentation time and lead to higher risk of the problem of off flavor by-products, bad sedimentation ability and unhealthy yeast. It is well known that healthy yeast makes better beer, thus the brewer must provide the best possible environment in which the yeast can growth and ferment happily. Healthy yeast will help brewery save costs. Zinc has a direct impact on the yeast’s performance, such as fermentation rate, flocculation, diacetyl reduction and yeast vitality at the end of fermentation for re-pitching.

(2)The benefits of proper zinc concentration in wort

• Promote fermentation rate, make the production capacity increase.

• Improve yeast flocculation, reduce filtration costs.

• Get higher viability and vitality yeast at end of fermentation for re-pitching.

• Contribute to beer foam stability.

Where is zinc form in brewing?

(1) The malts

During production of wort, the concentration of zinc gradually decreases and only small amount left in the wort. Only about 5-20% of the zinc in the malt goes into wort during mashing and the proportions dissolved is very variable. If the concentration of zinc does not reach the threshold of 0.15-0.3mg/L, the fermentation difficulties will happen.

(2) Drinking water

The level of zinc in drinking water is less than 1ppm, typically near 0.05ppm.

(3) Artificial addition

When you are on the way of brewing beer, you need consider the necessity of adding nutrient and which nutrient is important and necessary. Zinc is physiological importance for proteins synthesis, yeast growth and alcoholic fermentation in brewing. Zinc may be supplemented directly by adding, such as high zinc inactive yeast, zinc salt. The recommended level of zinc in wort is 0.3-0.5ppm for better yeast growth. If the concentration is not enough, the off-flavors will produce in beer and the heath of yeast will be bad for re-pitching.

When need to add zinc?

(1) High gravity fermentation

When wort has a particularly higher gravity, more than 1060, providing optimum Zinc will help yeast to improve alcohol tolerance and decrease the stress of high sugars. Zinc is important in yeast cell cycle and is a co-factor in enzymes that are responsible for alcohol production. Optimum zinc contain in wort has a positive impact on fermentation by having a quicker start and getting a high-gravity beer in the end.

(2) Re-pitching yeast

Guaranteeing a healthy yeast for next brewing, the use of nutrients is reasonable.

(3) Sugar adjunct wort

The wort with sugar adjuncts results in an increased requirement for Zinc.

The solutions for zinc deficiency

Zinc is a key component at the active site of yeast enzymes. In most wort, the zinc is not enough for good brewing and therefore many brewers add it to promote fermentation. It is key to success in brewing to guarantee optimum concentration of zinc in wort yeast. Too much Zinc is also toxic to yeast growth, so be sure to check the right concentration of the wort.

In zinc deficiency wort, the use of BrewNutri-Z is a good choice. BrewNutri-Z is an inactive yeast with high zinc. Inactivated yeast provides nutrients yeast needs to grow. BrewNutri-Z from Angel contains inactivated yeast with high Zinc for yeast to supply nutrients.

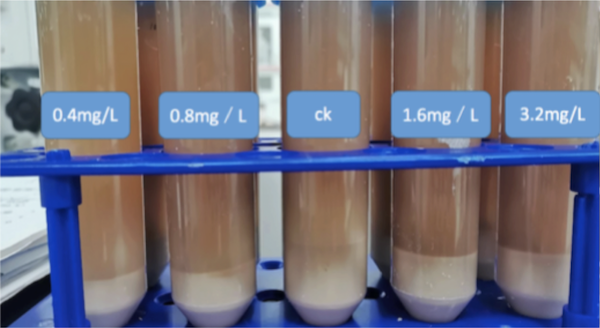

*The effect of BrewNutri-Z on yeast sedimentation

Which points are good for adding BrewNutri-Z?

Zinc supplied artificially may limit the availability depending on when it is added to wort. As one of the most important nutrients, zinc is added to the wort just before pitching the yeast. High zinc is not good for yeasts but small amount is essential.

(1) adding the nutrient in the last minutes before the end of the boil

(2) adding it directly into the fermenter once the wort has cooled down.

About Angel Brewing:

Angel brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Distilled Spirits and Biofuels Division:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

For more media information, please contact:

Angel Yeast Co., Ltd.

Yichang, Hubei, China

Ryan Wu

Tel.: +86 717 6353619

Email: wusy@angelyeast.com

en.angelyeast.com