Dec. 31th, 2019

By Tina Liao

Due to the energy crisis in the 1970s, people began to pay attention to the problem of the increasing depletion of petroleum resources and environmental pollution. It is imperative to study the bio fermentation energy to replace the traditional petroleum derived fuel. Ethanol fermentation technology is also constantly updated。

Conventionally,7-8% v/v ethanol is produced by fermenting medium containing 15-16% sugars. This process generates huge amounts of effluent,By adopting high gravity (HG) and/or very high gravity (VHG) fermentation technology, an improvement in the process productivity and a reduction in the effluent volume can be achieved with reduced process water requirements. In ethanol industry, HG mashes containing 25-30% w/v solids are generally used to achieve 12-14% v/v ethanol concentration. By definition, VHG fermentation technology deals with the preparation and fermentation to completion of mashes containing 27 g or more dissolved solids per 100 g mash VHG mashes with ≥35% w/v dissolved solids have been explored (by academia) to achieve >15% v/v ethanol。As the technology offers high ethanol yield, low waste generation and can be operated at low cost, it could be very efficient at industrial scale among different ethanol production methods. For this reason, we analyzed and studied the key points of alcohol high gravity mash fermentation.

Factors affecting VHG fermentation

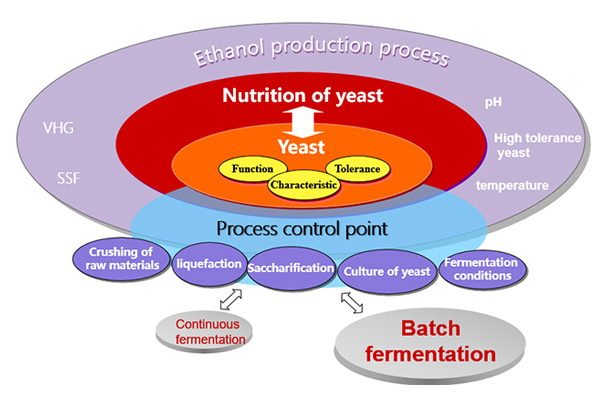

According to the figure, we can see the factors that affect the fermentation of ethanol high gravity mash. In addition to the factors of production equipment, the core factors are all from the strain, focusing on the nutrition, growth and fermentation conditions suitable for the strain.

In the process of ethanol fermentation, glucose osmotic stress produced substrate inhibition during VHG fermentation, which led to the slow growth of yeast, thus affecting the production of alcohol. At the same time, with the increase of alcohol concentration, the toxic effect on yeast also increased, so it is very important to select yeast with high alcohol resistance.

In VHG fermentation, if the supply of various nutrients is sufficient, the yeast can grow healthily, resist the osmotic pressure caused by high concentration of glucose to a certain extent, and keep the fermentation intensity at a high level. However, in the later stage of fermentation, with the lack of other nutrients, the normal metabolism of yeast is affected, and the low cell activity leads to the decline of fermentation capacity, which affects the thoroughness of final fermentation and the achievement of ideal alcohol precision. It is also very important to find and timely supplement such nutrients in the process of ethanol high gravity fermentation.

In addition, saccharification and liquefying are also very important. In high concentration fermentation, simultaneous saccharification fermentation (SSF) and batch fermentation are usually used,the fermentation temperature and dissolved oxygen may affect the efficiency of VHG fermentation.

In this year, we have studied yeast, nutrition and bacteriostatic products and their application technologies for the high-density mash ethanol fermentation process. In many large-scale alcohol factories in China, Angel high-concentration alcohol active dry yeast and yeast nutrition (hp11) were used in combination with process adjustment to carry out the high-density mash fermentation test, and achieved good application results.

About Angel Distilled spirits and Biofuels:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

|

Published by Tina Liao |

Press contact:

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86 717 6353619

Email: ethanol@angelyeast.com