Jan.5, 2021

By Fangfang

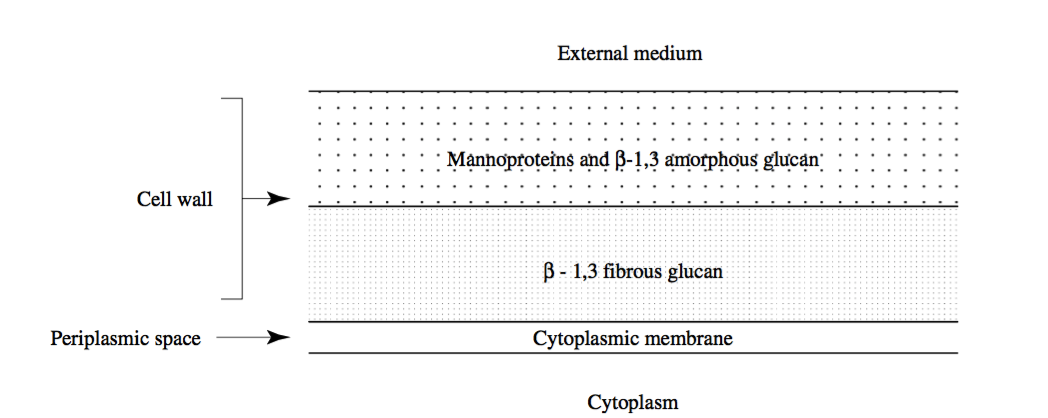

The yeast cell wall preparations are obtained from Saccharomyces spp. yeasts. The preparation mode must respect the surface area and consequently the adsorption capacity. They are used to prevent and deal with stuck fermentations. They have the property of fixing certain fatty acids (octanoic and decanoic) which disturb membrane permeability of yeasts. (OIV, Oeno 497-2013)

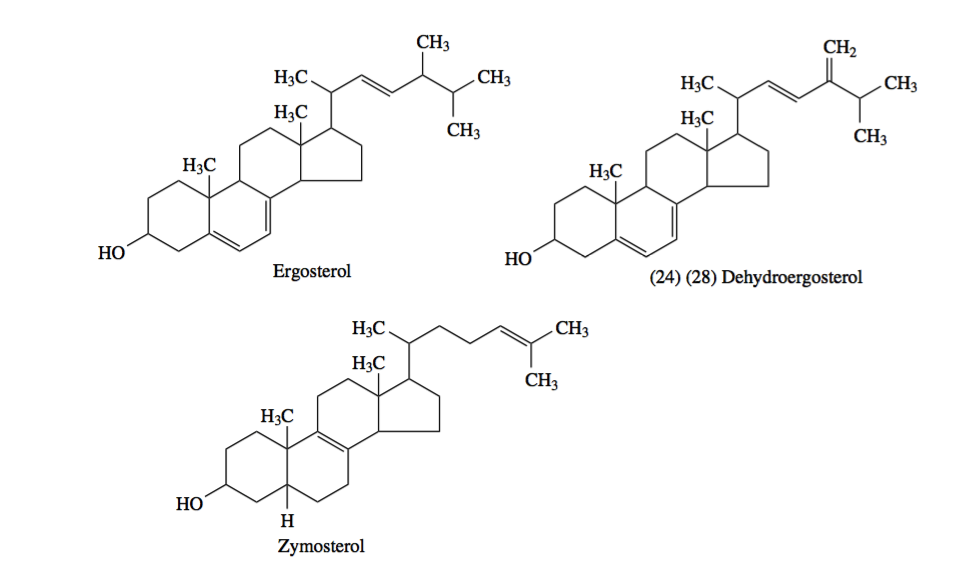

The cell wall of S. cerevisiae makes up 15–30% of the cell’s dry weight. The yeast cell wall preparations are generally recognized as fermentation activators. Yeast cell wall preparations contain lipids(unsaturated fatty acids, UFA)and Sterols. These compounds are termed “survival factors”. In the conditions of winemaking, deficiency of oxygen affects yeast growth and survival. Oxygen substitutes such as steroids and UFA can improve fermentation kinetics.

Fig. 1 Cellular organization of the cell wall of S. cerevisiae

Fig. 2 Principal yeast membrane sterols

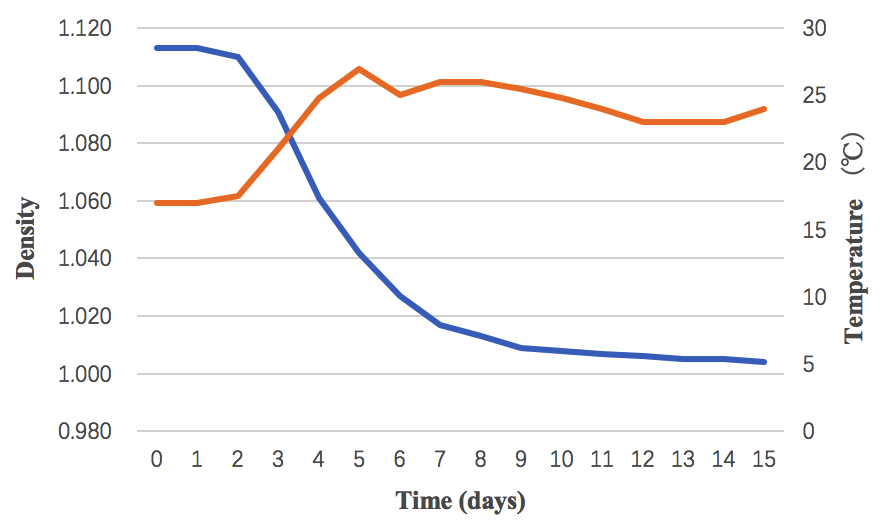

Stuck or sluggish fermentations have always been a major problem in winemaking. Higher sugar is not acceptable in dry white and red wines. A density that remains stable during 24 or 48 hours confirms a stuck fermentation which is difficult to restart.

Fig. 3 A stuck fermentation of Cabernet Sauvignon

There are many reasons of stuck or sluggish fermentations, such as deficiency of yeast assimilable nitrogen, lack of survival factors (long-chain unsaturated fatty acids, sterols), inhibition of enthanol and toxic medium-chain fatty acids (hexanoic, octanoic and decanoic acids).

The medium-chain fatty acids, such as hexanoic, octanoic and decanoic acids, are by-products of fatty acid metabolism during winemaking. The accumulation of medium-chain fatty acids during yeast fermentation can result in stuck or sluggish fermentations. When the medium-chain fatty acids permeate into the yeast cell at wine fermentation pH, the pH of intracellular part of wine yeast will decrease. The change of pH will affect the properties of the membrane.

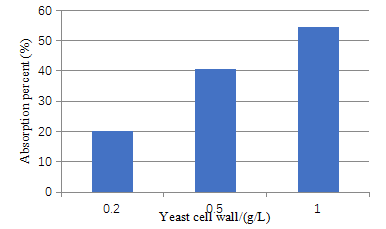

Yeast cell wall preparations have the ability to adsorb toxic compounds. Yeast cell wall preparations eliminate the inhibition of these toxic fatty acids by fixing them. Yeast cell wall has a large suface area with sorption ability to absorb residual chemicals and other toxic substances, such as medium-chain fatty acids.

Fig 4 Adsorption of decanoic acid by yeast cell wall in synthetic medium (Lafon-Lafourcade et al.1984)

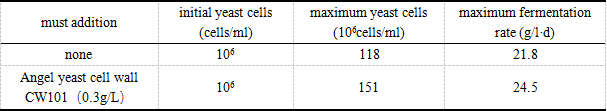

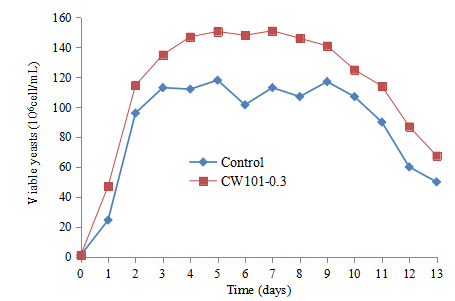

Yeast cell wall has an effect to eliminate inhibition compounds in wine must. Sterol compounds are necessary to keep cell membrane in good permeability. Yeast cell wall preparations have been proven to be effective in musts that are difficult to ferment, such as the must with high sugar concentrations or containing pesticide residues. The richness of(unsaturated fatty acids, UFA)and Sterols in cell wall preparation promotes the synthesis of yeast membranes and increase cell viabiltity and wine frementation (Table 1 and Fig. 5).

Table 1. Effect of Yeast Cell Wall CW101 on Yeast Growth and Fermentation Rate

Fig 5. Cell viability in 24 °Brix fermentations inoculated at 1 x 106 cells/ml.

(CW101-0.3: 0.3 g/l yeast cell wall CW101; Control: no yeast cell wall.)

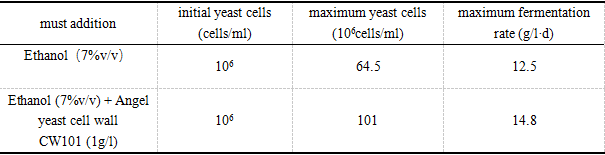

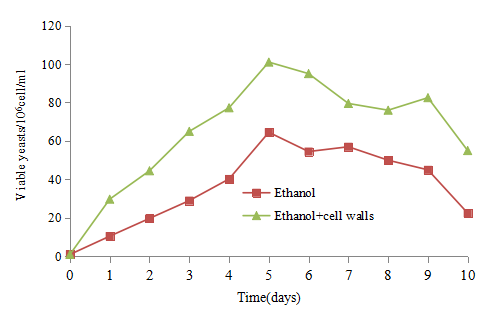

Membrane sterols, with the function of helping yeast to tolerate ethanol and medium-chain fatty acids, cannot be synthesized by yeast cells during winemaking fermentations. Addition of UFA or sterol to stuck and sluggish fermentations can often increase the fermentation rate. This effect can be achieved by addition of yeast cell wall preparations. Addition of yeast cell wall preparations CW101 in alcohol – adjusted grape juice increases yeasts growth and promote wine fermentation (Table 2 and Fig. 6).

Table 2. Effect on growth of yeast and fermentation rate by addition of yeast cell walls CW101 in alcohol-adjusted must

Fig 6 Cell viability in alcohol-adjusted must fermentations inoculated at 1 x 106 cells/ml.

(Ethanol:contained 7%v/v ethanol and 11. 4°Brix sugar;Ethanol+cell walls:contained 7%v/v ethanol, 1g/l yeast cell wall CW101 and 11. 4°Brix sugar)

As an oxygen substitutes, yeast cell wall preparations are known to stimulate rapid and complete fermentations of grape juices when adequate yeast asssimilable nitrogens are present. The property of fixing certain fatty acids (octanoic and decanoic) which disturb membrane permeability of yeasts increases the viability of yeasts and prolongs their fermentative activity. The addition of yeast cell wall is best way to restart a stuck fermentation. Currently, yeast cell wall is effective fermentation activators for winemaking.

References

Munoz E, Ingledew W. 1989. Effect of yeast hulls on stuck and sluggish wine fermentations: Importance of the lipid component. Appl Environ Microbiol, 55(6): 1560-1564

Pascal Ribe ́reau-Gayon Denis Dubourdieu Bernard Done`che Aline Lonvaud,2006,The Microbiology of Wine and Vinifications

Munoz E, Ingledew W. 1990. Yeast hulls in wine fermentations—a review. Journal of Wine research, 1(3): 197-209

| Published by Fang Fang |

About Angel Distilled spirits and Biofuels:

Angel can provide brewing yeasts, ingredients and related technical services for the production of wine, beer, and other brewing liquor. All our products are natural, safe, and of high quality. With the current energy shortages around the world, the production of fuel ethanol through yeast fermentation has become an inevitable trend.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86 717 6353619

Email: ethanol@angelyeast.com