-

Home > News & Events > Blog > Enzymes

May 15th, 2020

Rice is one of the main crops cultivated in the world. Except for some supply as daily diet, the most are used for industrial purposes, such as MSG production, starch sugar industry, etc. Rice is mainly composed of starch and protein, in which starch accounts for about 80% of the total weight of rice and protein only accounts for about 8%.

Rice protein is recognized as a high-quality vegetable protein and an important source of protein in people's diets. The well-balanced amino acid composition and hypoallergenic characteristics make it highly suitable for infants and special populations.

From the economic point of view, it is not appropriate to directly extract protein from rice for further processing, while rice residue, the by-product of organic acid, antibiotics and starch sugar production with rice as raw material, is a good raw material for deep processing of rice protein. Rice residue is the residue of rice flour liquefied by amylase at high temperature and filtered by plate and frame filtration to remove part of the carbohydrates. The rice residue, the protein content is more than 40%, which retains most of the protein in rice has almost the same nutrition as the protein extracted directly from rice.

China is rich in rice residue protein resources, and every 7 tons of rice consumed in starch sugar production will produce 1 ton of rice residue. However, due to the water-insoluble glutelin accounted for more than 80% of rice residue protein, and in the process of rice saccharification, the high temperature and pressure lead to the denaturation of rice protein and the formation of glycoprotein complex with sugar via Maillard reaction, resulting in the difficulty of protein extraction, poor solubility and emulsification, poor processing, so it is mainly used as feed, rarely used in food production 1.

Now enzyme can provide solutions, the rice protein can be extracted by turning it into soluble peptide through the degradation and modification of rice protein by enzymes so that the rice residue protein can be well utilized and applied in the nutrition and health food industry or pharmaceutical industry to further improved the comprehensive utilization of rice protein.

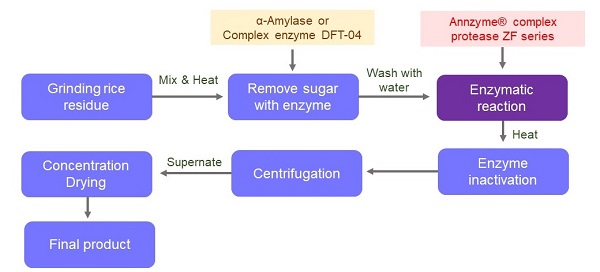

In addition to protein, the content of total sugar in rice residue is more than 30%. These residual sugars have been liquefied by amylase at high temperature in the process of rice saccharification, so there is little original starch, but more dextrin and oligosaccharide. Therefore, the treatment of the carbohydrate with α-amylase and glucoamylase in advance to increase the protein content of rice residue benefit the following process of the protein hydrolysis.

Application of enzymatic method to remove sugar and protein from rice residue

The rice protein obtained after removing sugar is insoluble in water, and further enzymatic modification is necessary to make the wide application in food production.

![]()

Annzyme® complex protease ZF series designed according to the characteristics of vegetable protein and various processing technologies. It can improve the solubility, emulsification and foaming of rice residue as well as enhance nutritional value by hydrolyzing rice protein into polypeptide and amino acid to further expand the application field of rice protein.

China is a large rice production country, which provides the basis for the development and utilization of rice protein. Rice protein, as a plant protein resource with great development value, can be further improved on the comprehensive utilization by enzymes.

Reference:

(1) Jiang Li,Lin Tao,Zhao Xiaohu,et al. Extraction of protein from rice dreg using purifying and enzyme treating[J]. Food Science and Technology,2011,36(12):179-182.

By Zhan Fei

Institute of Special Enzymes and Biological Products

Related product please check:

https://en.angelyeast.com/products/enzymes/complex-enzyme-dft-04.html

About Annzyme®:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

About Special Enzyme Division :

Angel Special Enzyme Division is an important strategic business unit of Angel Yeast. Related technologies involve the fields of microbial breeding, genetic engineering, fermentation engineering, biocatalysis, food, brewing, feed, pharmaceutical, etc.

About Angel :

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel& Fax: +86-717-6369520

Email: enzyme@angelyeast.com