-

Home > News & Events > Blog > Yeast & Baking

When making fried foods, users often face issues with the stability of regular baking powder in high-moisture batters, leading to premature deactivation. Additionally, during the frying process, regular baking powder lacks sustained gas production, resulting in products that are not crispy, fluffy, or well-colored enough. Addressing these challenges for large-scale fried products like chicken wings, tempura, crispy pork, and lotus root chips, Angel has proposed a solution by diligently developing a specialized baking powder for frying, effectively meeting consumers' dual demands for texture and health.

I. Specialized Baking Powder for Frying Enhances Crispiness and Color

Baking powder, a food additive mainly composed of sodium bicarbonate, acidic substances (such as phosphates), and starch, is used to improve the softness and texture of food.

The specialized baking powder for frying adopts a ratio suitable for high-temperature frying conditions while prioritizing aluminum-free health considerations. It enhances the stability of baking powder, ensuring a greater and more enduring gas production during frying. As a result, fried products become more crispy, fluffy, and exhibit a golden and appealing color.

Fig.1 A comparison of the effects of using regular baking powder and specialized baking powder for frying in the fried chicken making process (Left: Display of the effect using regular baking powder, Right: Display of the effect using specialized baking powder for frying)

II. Two Factors Making Specialized Baking Powder for Frying the Optimal Substitute

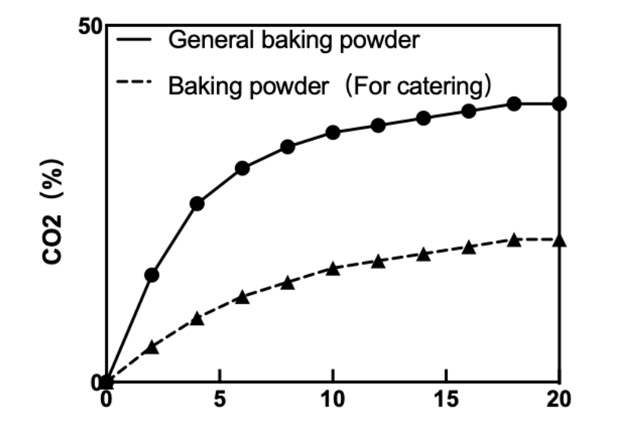

Fig. 2 Relationship between the resting time of batter and the carbon dioxide production of baking powder (It is evident that specialized baking powder for frying is more stable during batter resting compared to regular baking powder)

Strong Stability in Batter: When making regular batter-coated products, the batter usually needs to sit for an extended period. This baking powder maintains the stability of the batter during this time, not deactivating in high-moisture conditions, ensuring effective gas production and leavening during the frying process.

Prolonged Gas Production with Larger Volume: Regular baking powder tends to have an explosive gas production during frying, lacking endurance and resulting in products with insufficient shell integrity and poor expansion. The specialized baking powder for frying provides sustained and substantial gas production, achieving excellent scale and fluffiness while ensuring proper adhesion of the crispy shell.

III. Advantages of Specialized Baking Powder for Frying

Texture Upgrade: Enhances the crispiness and tenderness of fried foods, achieving a uniform scaling on the surface and offering a rich and layered texture that satisfies modern consumers' preferences.

Stability and Endurance: Maintains low gas production during batter resting, ensuring consistency in product quality. During frying, it exhibits prolonged and substantial gas production, especially suitable for high-temperature frying.

Color Promotion: Promotes the occurrence of Maillard reaction during heating, creating a porous structure inside the food, increasing the surface area, and facilitating color development during frying.

Aluminum-Free and Harmless: Healthier than traditional baking powders containing alum, reducing the harmful effects of long-term excessive aluminum intake. Additionally, it has a relatively low sodium content.

Safety Assurance: The addition of baking powder promotes the formation of a loose structure in the coating, increases surface area, facilitates heat exchange during frying, lowers frying temperatures, and reduces the generation of harmful substances, ensuring consumers can eat more safely and confidently.

IV. Technical Application of Specialized Baking Powder for Frying in Chicken Cutlets

The specialized baking powder for frying can be used in the production of fried chicken, tempura, and other fried batter-coated products, with an addition rate of 0.5-3.0% of the flour quantity. This ensures both the desired texture of the food and meets the efficient processing needs of the catering industry, making it a popular choice among consumers.

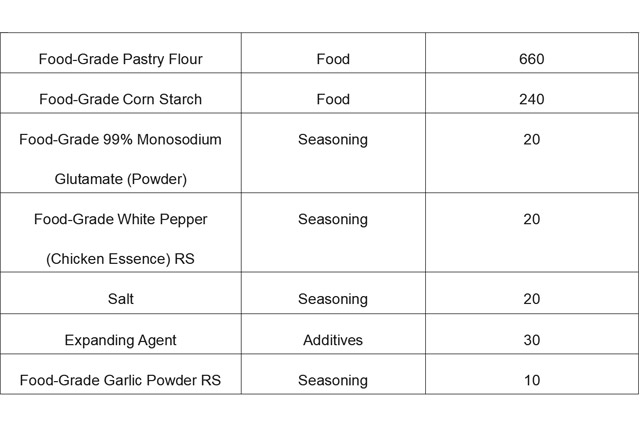

Formula:

Liquid to Material Ratio = 100g:100g

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press Contact

ANGEL YEAST CO.,LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86-717-6369520, 6369558

Fax: +86-717-6370680

Email: zhangchen@angelyeast.com