The freeze-drying survival rate of lactic acid bacteria is widely recognised as a key technical indicator and characteristic in its production and application across the food industry.1

Furthermore, a study concerning the impact of cultivation strategy, freeze-drying process, and storage conditions on survival, membrane integrity, and inactivation kinetics of Bifidobacterium longum, concluded that the choice of cultivation conditions provided “the biggest potential of increasing the survival after drying”.2

Lyophilization – the process of freeze-drying – is important in the production and processing of lactic acid bacteria because it effectively improves the stability of live bacteria and the qualification rate and shelf life of products. And this can have significant benefits for the probiotic industry.3

Now, a recent publication of a two-year study carried out by Angel Yeast has concluded that nucleic acids in yeast extract have significant positive effect on improving the biomass and survival rate of Lactobacillus acidophilus during the cultivation and freeze-drying process. This finding is believed to offer significant potential for manufacturers to improve productivity and shelf life of starter cultures and probiotic dietary supplements.

Xiong Changwu, Senior Engineer of Protein Nutrition and Seasoning Technology Center of Angel Yeast, says the findings of the study present a range of opportunities for the development of special-nutrition yeast strains within the yeast industry. Changwu says: “As well as promoting the development of the yeast industry, this conclusion will contribute to the advancement of product and technology of probiotic manufacturers and propel the industry to undertake further research.”

Effects of yeast extract on Lactobacillus acidophilus

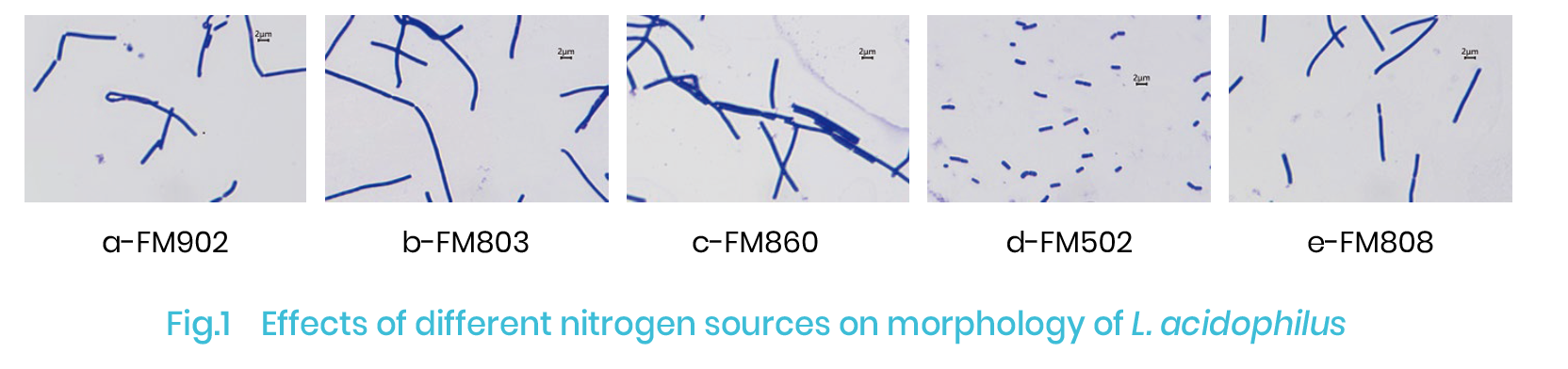

By carrying out a range of freeze-drying experiments and analysing the effects of nitrogen sources in the culture medium on the morphology of Lactobacillus acidophilus, the study found that yeast extract FM502 – used as the nitrogen source to cultivate the shortest bacteria – increased the number of viable bacteria by changing the shape and shortening the length of the cells. It also had the highest relative freeze-drying survival rate compared with similar products; in fact, its survival rate was shown to be twice that of other yeast extracts.

As such, the study concluded that the morphology of Lactobacillus acidophilus improves the stability of the bacteria by promoting the division of lactic acid bacteria, stabilising the shape of the bacteria and, in turn, increasing the number of viable bacteria per unit of fermentation. “By the use of special yeast extract, the shorter length of the bacteria improves the physiological state of microorganisms. In addition, reducing the length-width ratio by shortening length of bacteria makes the bacteria tend to be spherical which promotes better resistance during the freeze-drying process, a common understanding in the industry,” explains Changwu. “Therefore, shortening the length helps to improve the survival rate of lyophilization to a certain extent.”

Lactobacillus acidophilus is a non-spore-bearing bacillus, in chain-rod or clavate shape. It is considered a beneficial microorganism in human and animal intestines, linked to intestinal health. It is also one of the common strains in human dietary supplements, dairy drinks and feed additives.4 Current literature has detailed that Lactobacillus acidophilus belongs to a microorganism with strict nutritional requirements5, weak autogenous anabolic capacity6 and high nutritional requirements for culture media7, and the lack of some nutrients can lead to changes in the state of the bacterium.

Yeast extracts impacting morphology

According to current studies, the morphology of the bacteria is affected by the growth conditions on the one hand8, and the nutritional conditions of the culture medium on the other hand.9 Microscopic examination results [Figure 1] show that the morphology of Lactobacillus acidophilus displayed significant differences when it was cultured on the medium prepared by different yeast extracts (all derived from baker’s yeast) under the same conditions.

Of these, the bacteria with yeast extract FM502 as the nitrogen source was the shortest, with a uniform length of about 2μm (micrometres), while the morphology of Lactobacillus acidophilus cultured with other yeast extracts were longer, reaching up to between 6 to 8μm.

Fermentation Nutrients – products and applications

Harnessing and developing the potential of yeast technology leads to products and solutions for manufacturers across a range of sectors in the food industry, from baking and seasoning to distilling and brewing. Angel Fermentation Nutrients concentrate on microbial fermentation and cell culture nutrient source, from research and development through to production and promotion of products and new technologies.

Yeast extract can be used as a raw culture medium for lactic acid bacteria, as well as a protective agent for live bacteria preparation. Adding a controlled amount of yeast extract, typically 1-3%, to the culture medium can help manufacturers of lactic acid bacteria to improve biomass and stability. Furthermore, as the study indicates, yeast extract can also be added as a protective agent during the lyophilization process to improve the survival rate during freeze-drying.

Through the process of yeast technology, the development of yeast sources, animal and plant sources, composite media and other microbial nutrition product systems, a range of formula and solutions can be established. Fermentation processes using bacteria, yeast, fungi and animal cells as the production host, span a range of industry applications within food ingredients, feed ingredients, biochemical, bio-pharmaceutical and bio-agriculture materials. Product ranges include:

• Yeast powder fermentation

Nutrients contained within inactive yeast (such as YP108 and YP600) and autolyzed yeast (such as YA801) are released slowly from intact cells during fermentation. This longer fermentation helps to maintain the stability of fermentation process and results in a protein and nutrient-rich product that is also a cost-effective application in industry.

• Yeast extract fermentation

Yeast extract is rich in free amino acids, peptides, vitamins, nucleotides, trace elements and growth factors. Nutrient-enriched yeast extract (such as FM985 and FM502) is used in the probiotics industry and includes a series of fermentation nutrients for the cultivation of lactic acid bacteria, bacillus, starter cultures and other specific strains for dietary supplements.

• Peptone

Peptone is concentrated by peptides, amino acid and vitamins, widely used in the fermentation industry and dehydrated culture media. Yeast peptone (FP101, 102 and 103) is a food grade, allergen-free, non-GMO and traceable product which serves as an alternative of peptones derived from animals.

• Culture media

Serving the requirements of food culture, vaccines and ready-to-use medium, Angel develop and promote culture media, designed to serve the fermentation process. Products within the food processing industry include vinegar starter (a liquid fermentation of vinegar which has a fast acid production rate and high production efficiency) and mushroom medium (a liquid cultivation of mushroom which accelerates spore germination and mycelial / root growth).

About Angel Yeast

Founded in 1986, Angel Yeast Co., Ltd specializes in the production of yeast and yeast derivatives. Its product range includes baker's yeast and ingredients, Chinese dim sum and seasoning, savory yeast extract, human health, animal nutrition, plant nutrition, distilled spirits and biofuels, microbial nutrition and enzymes.

References

1 Das, D., Goyal, A. (2012). Lactic Acid Bacteria in Food Industry. In: Satyanarayana, T., Johri, B. (eds) Microorganisms in Sustainable Agriculture and Biotechnology. Springer, Dordrecht.

2 Haindl, R., Neumayr, A., Frey A., Kulozik U. (2020). Impact of cultivation strategy, freeze-drying process, and storage conditions on survival, membrane integrity, and inactivation kinetics of Bifidobacterium longum.

3 Senz, M., Bernhard van Lengerich, B., Bader, J., Stahl, U. (2014). Control of cell morphology of probiotic Lactobacillus acidophilus for enhanced cell stability during industrial processing.

4 Imbert M., Blondeau R. On the iron requirement of lactobacilli grown in chemically defined medium[J]. Current microbiology, 1998, 37(1): 64-66.

5 Soska J., Koukalová B., Reich J. Control of and synthesis in Lactobacillus acidophilus Role of RNA and free amino acids[J]. Biochimica et biophysica acta, 1976, 447(1): 45.

6 Dreizen S., Reed A I., Spies T D. Salivary mucin as a source of essential amino acids for the Lactobacillus acidophilus (Hadley)[J]. J Dent Res, 1950, 29(6): 774-778.

7 R. H. Deibel M D C F. Filament formation by lactobacillus leichmannii when desoxyribosides replace vitamin b12 in the growth medium1 2[J]. Journal of Bacteriology, 1956.

8 Schar-Zammaretti P., Schär-Zammaretti P., Dillmann M., D'Amico N, et al. Influence of Fermentation Medium Composition on Physicochemical Surface Properties of Lactobacillus acidophilus[J]. Applied and Environmental Microbiology, 2005, 71(12): 8165-8173.

9 Soska J. Growth of Lactobacillus acidophilus in the absence of folic acid[J]. Journal of Bacteriology, 1966, 91(5): 1840-1847.