Angel Yeast provides a series of active yeast products, which are applied in the manufacturing of specific biological products and the removal of saccharide materials in substrates. The following is a detailed introduction to the phosphorylation of adenosine into ATP and the conversion and accumulation of glucose into fructose 1,6-diphosphate (FDP) by yeast.

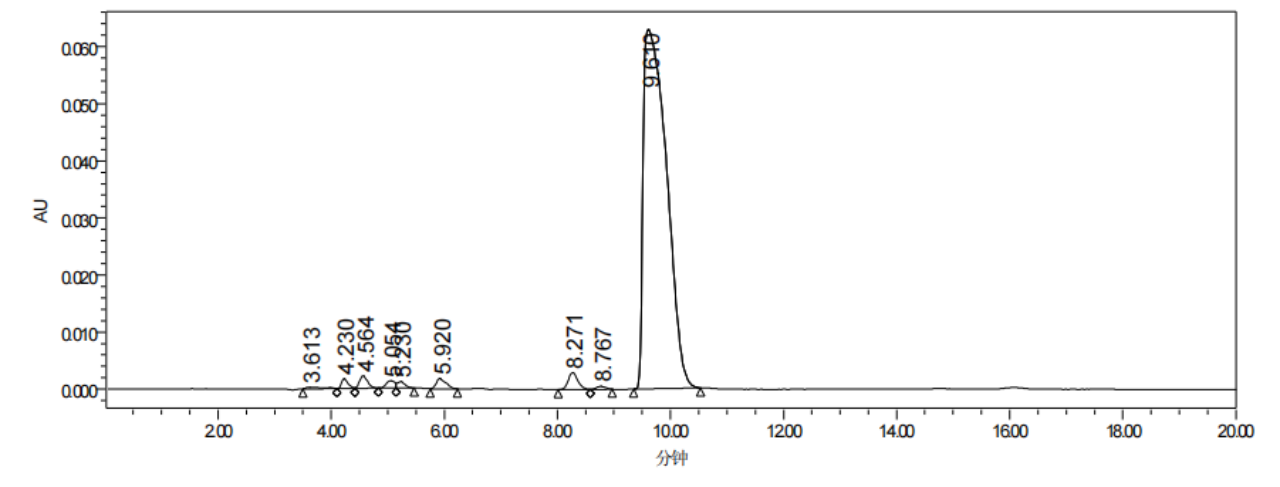

Adenosine can combine with high-energy phosphate bonds to form triphosphate compounds under the catalysis of active yeast. To improve the efficiency of adenosine phosphorylation, Angel Yeast has selected the high-efficiency catalytic active yeast YA400 for the ATP industry. For the convenience of users, the researchers at Angel Yeast have established a biocatalytic process matching YA400. Currently, using YA400 with 3% adenosine substrate, complete conversion of the adenosine substrate can be achieved in approximately 5 hours, and more than 90% of the adenosine substrate is converted into ATP. Figure 1 shows the HPLC chromatogram of adenosine conversion to ATP. Compared with the use of traditional beer yeast, YA400 has the following advantages:

(1)YA400 is stored at room temperature with a 2-year shelf life. The matching process does not require freeze-breaking of cell walls. No need for cold storage facilities, reducing equipment investment and cold storage maintenance costs ;

(2)YA400 is a pure-cultured baker's yeast with higher stability;

(3)YA400 is a granular product, easy to use;

(4)YA400 has a light color, facilitating the post-processing of ATP products;

(5)YA400 has high activity, and its dosage is less than 20% of that of beer yeast (beer yeast with 40% moisture), greatly reducing the load of post-catalysis treatment.

In addition to phosphorylating adenosine to produce ATP, YA400 can also phosphorylate other nucleoside substrates to prepare NTP.

Figure 1. HPLC analysis of ATP generation from YA400 phosphate, a 3% adenosine substrate

(Note: 9.61min is the ATP peak, 16min is the adenosine substrate peak time)

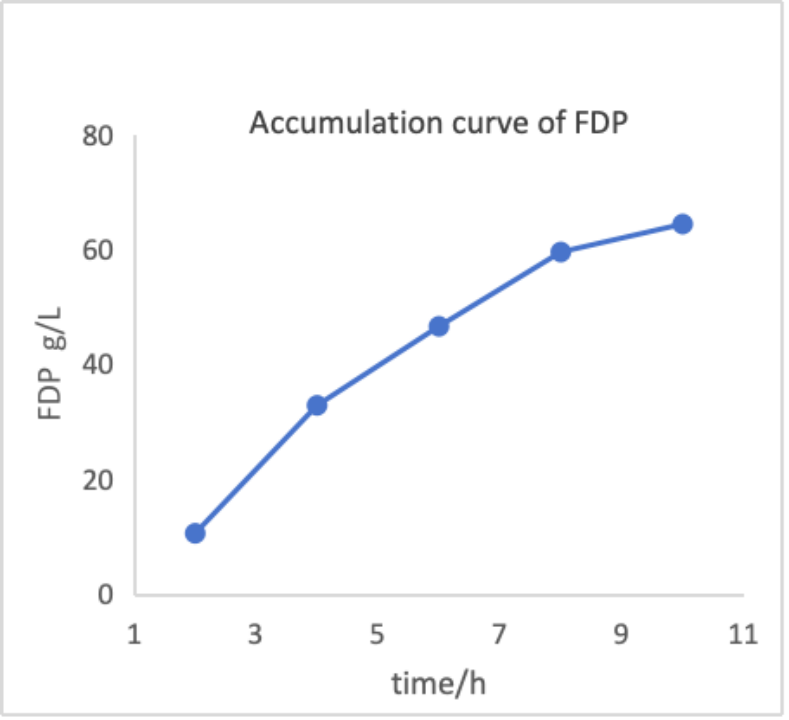

Fructose 1,6-diphosphate can be prepared by converting glucose via active yeast. For this conversion reaction, Angel Yeast has developed YA700 and a matching conversion process. Currently, using YA700, approximately 10% glucose can be completely consumed in about 10 hours, with the fructose 1,6-diphosphate accumulation exceeding 60g/L. Compared with the traditional beer yeast process, the selection of YA700 , YA700 has the following advantages:

(1)YA700 is stored at room temperature with a 2-year shelf life. The matching process does not require freeze-breaking of cell walls. No need for cold storage facilities, reducing equipment investment and cold storage maintenance costs ;

(2)YA700 is a pure-cultured baker's yeast with higher stability;

(3)YA700 is a granular product, which is easy to use;

(4)YA700 has a light color, lowering the post-processing cost of fructose 1,6-diphosphate;

(5)YA700 has high activity, and its dosage is only 1/6 of that of beer yeast slurry, reducing the load of post-catalysis treatment.

Figure 2. Concentration variation curve of YA700 converting glucose to FDP

In addition to the applications in the aforementioned catalytic fields, in some manufacturing areas, feed liquids contain a large amount of saccharide impurities, such as glucose, fructose, sucrose, etc., which affect the extraction of target products or the physicochemical properties of final products. Such feed liquids have high osmotic pressure and require rapid and efficient removal of saccharide impurities. To address this challenge, the R&D team at Angel Yeast has developed YA200. This product has a viable cell count of over 20 billion per gram and can tolerate over 25% glucose or 20% alcohol. Engineers from Angel Yeast can provide reference application solutions for specific application scenarios.

About Angel Fermentation Nutrients:

Angel Fermentation Nutrients, rich in protein, amino acids, peptides, nucleotides, B vitamins, and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency, and stable quality, Angel YE are widely applied in biological laboratories and industrial-scale fermentation, promoting product safety and technical progress in the global fermentation industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 160 countries and regions.

Press contact:

email: yef@angelyeast.com