September 20, 2025

Zhang Song

Fungal liquid cultivation is a technique that allows fungi to grow and proliferate in a liquid culture medium. Oxygen is supplied through aeration and agitation or airlift systems to disperse the fungal biomass. This method is widely used in industrial and agricultural production.

Compared with traditional solid-state cultivation, fungal liquid cultivation offers several significant advantages:

- Short Growth Cycle: Mycelia can contact nutrients more uniformly and rapidly in liquid, leading to faster growth and reproduction. Liquid culture typically takes 5–7 days to prepare inoculum, whereas solid cultivation may require about 30 days.

- Uniform Mycelial Age: The age difference between different parts of the mycelium is small in liquid culture. The mycelium grows vigorously with strong vitality.

- High Production Efficiency and Easy Scalability: Facilitates industrial automation, offers high output per unit volume, and short production cycles.

- Easy Product Extraction: Mycelia and metabolites can be easily separated and purified from the culture broth through filtration, centrifugation, extraction, etc.

Introduction to Fungal Liquid Culture Media

Fungal liquid culture technology is widely applied in the following areas

- Edible mushroom inoculum production: Liquid inoculum is used for inoculating solid cultivation substrates. It accelerates mycelial growth, ensures uniform age, and shortens the cultivation cycle.

- Bioactive substance production: Many fungi produce physiologically active metabolites such as polysaccharides, antibiotics, and enzymes. Liquid fermentation enables large-scale production.

- Food and feed additives: Cultivated fungal mycelia (e.g., yeast, Aspergillus) serve as protein sources or produce flavor compounds.

- Biocontrol and agricultural applications: Production of biopesticides, such as Beauveria bassiana and Trichoderma, for controlling agricultural pests and diseases.

- Medical research and clinical applications: Used for identification of pathogenic fungi and drug susceptibility testing to support clinical diagnosis and treatment.

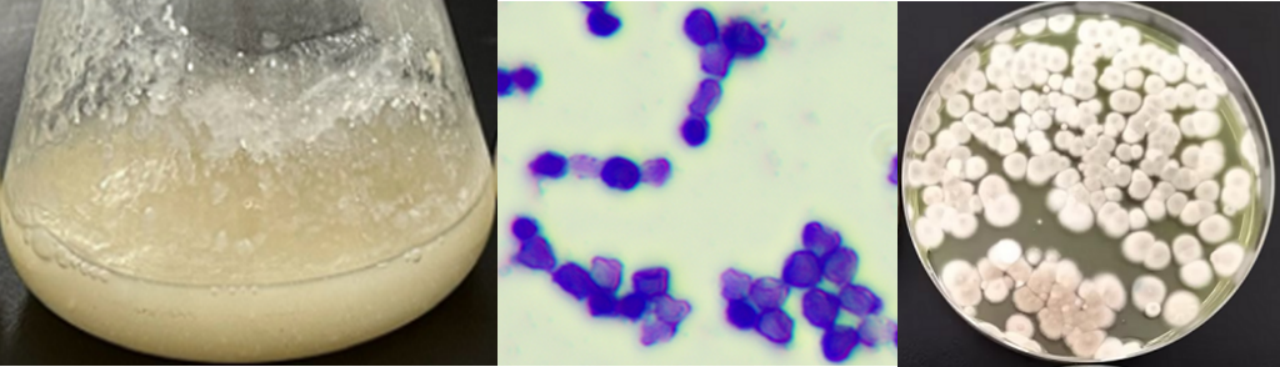

*Liquid Inoculum Production of Enoki Mushroom

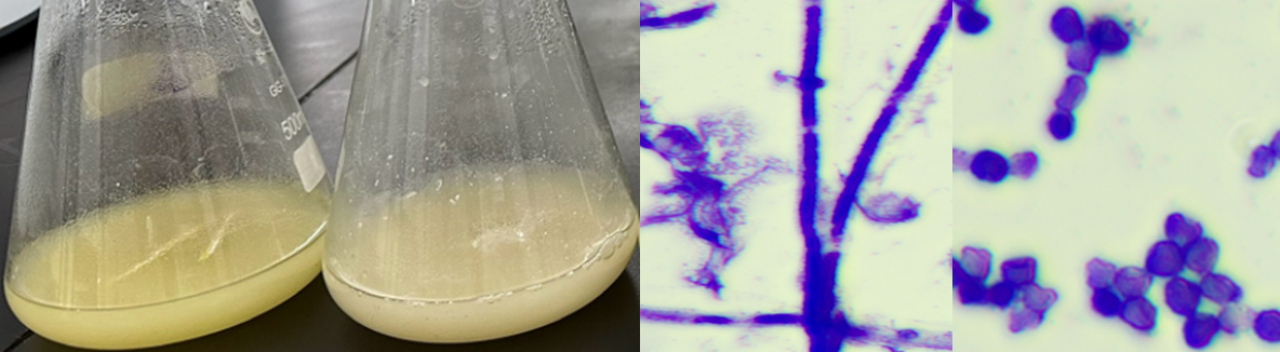

*Liquid Fermentation Production of Trichoderma

Fungal liquid culture media contain large amounts of carbohydrates, essential inorganic salts, growth factors, and in most cases, complex organic nitrogen sources.

| Model | Main Ingredients | Product Advantages | Dosage |

| MP200 | Glucose, yeast extract, soybean meal, potato powder, peptone, phosphate | Comprehensive nutrition, high versatility; for edible mushroom inoculum cultivation | 15.0 g/L |

| MP300-S | Glucose, yeast extract, potato powder, phosphate | Food-grade, free of animal-derived and allergenic ingredients; for edible/medicinal fungal liquid culture | 15.0 g/L |

| MP500 | Glucose, peptone, inorganic salts | For liquid cultivation of agricultural fungi such as Beauveria bassiana and Trichoderma | 16.3 g/L |

| YNB | Glucose, vitamins, ammonium sulfate, inorganic salts, trace elements | Chemically defined medium for scientific research or industrial yeast liquid culture | 6.7 g/L |

The powdered fungal liquid culture media are off-white. Some types form a relatively uniform turbid liquid when dissolved. As fungi utilize nutrients, the solution gradually clarifies.

Product Features:

- Rich Nutrition: The carbon-to-nitrogen ratio and mineral elements in the fungal liquid media are optimized to significantly enhance fungal biomass and vitality.

- Convenient Use: Ready-to-use composite media are easy to prepare and can be directly applied, saving labor costs.

- Quality Assurance: Strict raw material control and precise mixing processes ensure consistent quality and safety. MP300-S meets food-grade, non-animal-derived, and non-allergenic requirements. YNB meets fermentation needs in research and vaccine production.

Application Cases of Fungal Liquid Culture Media

In the liquid inoculum culture of Enoki mushrooms, MP300-S resulted in smaller and more numerous fungal pellets with higher sugar utilization efficiency. The physiological state of the early-stage inoculum significantly affects the production cycle in bag cultivation. Under the same conditions, Enoki liquid inoculum cultured with MP300-S showed faster fruiting and higher average yield.

In the liquid culture of Beauveria bassiana, MP500 increased dry weight by 50% compared to the control and accelerated sporulation.

MP300-S can be used for liquid inoculum culture of edible mushrooms but is less effective for species requiring animal-derived peptone. It is also suitable for medicinal fungi, fungal peptides, and fungal mycelial protein production. MP200 is mainly used for edible mushroom liquid inoculum culture. MP500 is specifically designed for liquid fermentation of agricultural fungi. YNB is used for high-quality yeast liquid fermentation. Therefore, the appropriate medium should be selected based on the nutritional characteristics of the fungal species.

| Fungal Liquid Culture Media | |||||

| Product Series | Edible Fungus Seed Cultivation | Fungal Polysaccharide Fermentation | Fungal Mycelium Fermentation | Agricultural Fungus Cultivation | Yeast Cultivation |

| MP200 | Recommended | Effective | Effective | ||

| MP300-S | Recommended | Recommended | Recommended | ||

| MP500 | Recommended | ||||

| YNB | Recommended | ||||

About Angel Fermentation Nutrients:

Angel Fermentation Nutrients, rich in protein, amino acids, peptides, nucleotides, B vitamins, and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency, and stable quality, Angel YE are widely applied in biological laboratories and industrial-scale fermentation, promoting product safety and technical progress in the global fermentation industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 160 countries and regions.

Press contact:

email: yef@angelyeast.com