May 8, 2019

By Yinqiang

1. General process of Bacillus subtilis fermentation

Plate culture—Shake flask culture--Fermentation

2. Key point

- Organic nitrogen source: better to use yeast extract

- Ventilation rate: generally around 1:0.8 to 1:1

- Working volume: generally around 50%-60%

3. How to do Bacillus subtilis fermentation?

a. Step of Seed culture

Formula of culture medium

corn starch 2. 0%

glucose 1%

Angel yeast extract FM902 2. 0%-3. 0%

amylase 0.02%

KH2PO4 0.1%

K2HPO4 0.1%

Antifoam 0.1%

Adjust the initial PH to 7. 0

Pretreatment of the corn starch (90 ℃10 min)

Sterilization process 121℃30 min

Control of fermentation process

Temperature 37 ℃, Ventilation rate 1:1 vvm, Pressure of the fermenter 0.1 MPa, Fermentation time 16-20h.

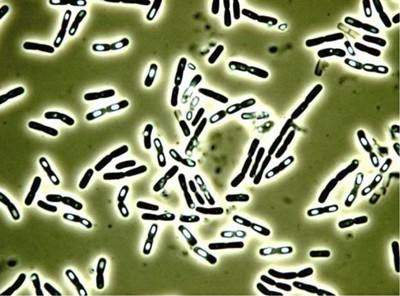

Check the seed culture under microscope, make sure there is no contamination from other microorganisms. Then transfer to fermentation vessel

b. Step of fermentation culture

Formula of culture media

Corn starch 3. 5%

Glucose 1%

Angel yeast extract FM902 2. 0%-3. 0%

KH2PO4 0.1%

K2HPO4 0.1%

Amylase 0.02%

Antifoam 0.1% (when the foam rise, fed antifoam slowly and carefully until foam decrease)

Adjust the initial PH to 7. 0

Pretreatment to the corn starch (90 ℃10 min)

Sterilization process 121℃30 min

Control of fermentation process

Temperature 37 ℃, ventilation rate 1:1 vvm, pressure of the fermenter 0.5 MPa,

Fermentation time 24-36h

4. How to optimize the fermentation time?

After 24h of fermentation, take the sample from fermentation tank, dilute it in 105\106\107 , each gradient plate 3 TSA plate, culture in 37 degree for 12 h, and compare the counts of each time(24\26\28\30\32\34\36\38\40h), and next time you would know which time is the best time for ending the fermentation process. For spore it’s the same.

| Published by Yin Qiang Senior manager of Angel Yeast APAC Division |

About Angel Microbial Nutrition