April 26, 2020

By Yinqiang

Microbial fermentation engineering refers to the use of modern engineering techniques to make use of certain specific functions of microorganisms to produce useful products for human, or a new technology that directly applies microorganisms to industrial production processes. The content of fermentation engineering includes the selection of strains, the preparation of culture medium, sterilization, expansion of culture and inoculation, fermentation process and product separation and purification. Fermentation engineering plays a key role in the industrialization of biotechnology.

1. "Fermentation" includes "fermentation strictly defined by microbial physiology" and "industrial fermentation". "Fermentation" in "fermentation engineering" should be "industrial fermentation".

2. In industrial production, products are processed or produced through "industrial fermentation". So the corresponding processing or production process is called "fermentation process". In order to achieve industrial production, it is necessary to solve the engineering problems of the industrial production environment, equipment and process control for realizing these processes (fermentation processes). Therefore, there is a "fermentation project".

3. Fermentation engineering is a discipline used to solve the engineering problems of industrial production according to fermentation technology. From the perspective of engineering, fermentation engineering divides the fermentation industrial process into three stages: strain, fermentation and refining (including wastewater treatment). These three stages have their own engineering problems, which are generally called upstream, midstream and downstream engineering of fermentation.

4. Microorganism is the soul of fermentation engineering. In recent years, the understanding of the biological properties of fermentation engineering has become clearer, and fermentation engineering is approaching science.

5. The most basic principle of fermentation engineering is the biological principle of fermentation engineering.

Fermentation engineering refers to a kind of engineering technology that uses certain functions of organisms (mainly microorganisms) and active in vitro enzymes to produce useful biological products for humans, or directly uses microorganisms to participate in the control of certain industrial production processes technology. It is well known that yeast fermentation is used to produce beer, fruit wine and industrial alcohol; lactic acid bacteria fermentation is used to produce cheese and yogurt, and the use of fungi to produce penicillin on a large scale is an example of this. With the advancement of science and technology, fermentation technology has also made great progress, and has entered the stage of modern fermentation engineering that can artificially control and transform microorganisms so that these microorganisms produce products for humans. As an important part of modern biotechnology, modern fermentation engineering has broad application prospects. For example, genetic engineering methods are used to purposely transform the original strains and increase their yield; the use of microbial fermentation to produce drugs, such as human insulin, interferon and growth hormone.

It has evolved from the simple production of alcoholic beverages, acetic acid and bread in the past to today, it has become an extremely important branch of bioengineering, including microbiology, chemical engineering, genetic engineering, cell engineering, mechanical engineering and computer hardware & software multidisciplinary project of engineering. Modern fermentation projects not only produce alcoholic beverages, acetic acid and bread, but also produce various medical and health care drugs such as insulin, interferon, growth hormone, antibiotics and vaccines, as well as agricultural pesticides, bacterial fertilizers and microbial herbicides. In the chemical industry, it produces amino acids, spices, biopolymers, enzymes, vitamins and single-cell proteins.

Broadly speaking, fermentation engineering consists of three parts: upstream engineering, midstream engineering and downstream engineering.Among them, the upstream project includes the cultivation of excellent strains, the determination of optimal fermentation conditions (pH, temperature, dissolved oxygen and nutrient composition), and the preparation of nutrients. The midstream project mainly refers to the process technology for cultivating cells and producing metabolites in a large number of fermentation tanks under optimal fermentation conditions. There must be a strict aseptic growth environment, including the technology of using high temperature and high pressure to sterilize the fermentation raw materials and fermentation tanks and various connecting pipes before the start of fermentation; during the fermentation process, continuous introduction of dry sterile air into the fermentation tank and air filtration technology; computer control technology that controls the feed rate according to cell growth requirements during fermentation; and different process technologies for seed culture and production culture.

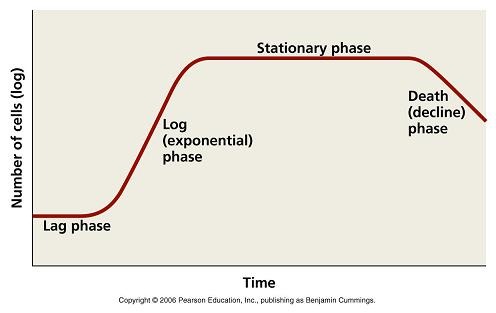

In addition, according to different needs, the fermentation process is also classified into batch fermentation: that is, one-feed fermentation; fed-batch fermentation: that is, on the basis of one-feed fermentation, a certain amount of nutrients is added to make the cells grow further, or get more metabolites; Continuous fermentation: Continuous feeding of nutrients and continuous extraction of fermentation broth.

Before any large-scale industrial fermentation, a large number of experiments must be carried out in a small laboratory fermenter to obtain the kinetic model of product formation, and the fermentation requirements of the pilot plant should be designed according to this model. Finally, the pilot data should be designed to be larger. Kinetic model of large-scale production. Due to the complexity of biological reactions, many problems will occur in the process from the laboratory to the pilot test, from the pilot test to large-scale production. This is the problem of fermentation engineering process amplification. Downstream engineering refers to the technology of separating and purifying products from fermentation broth: including solid-liquid separation technology (centrifugal separation, filtration separation, precipitation separation and other processes), cell wall breaking technology (ultrasonic, high-pressure shear, osmotic pressure, surfactant and Lysozyme, etc.), protein purification technology (precipitation method, chromatographic separation method, ultrafiltration method, etc.), and finally the packaging technology of the product (vacuum drying and freezing drying, etc.).

In addition, in the fermentation industry for the production of medicines and foods, it is necessary to strictly abide by the regulations of cGMPs published by the US Federal Food and Drug Administration, and to receive regular inspection and supervision by the relevant authorities.

Three stages of fermentation production process

Upstream, midstream and downstream. First select high-performance production strains for selection; then carry out large-scale cultivation in manual or computer-controlled biochemical reactors to produce the target metabolites; and finally collect and purify the target products to obtain the desired products.

| Published by Yin Qiang Senior manager of Angel Yeast APAC Division |

About Angel Microbial Nutrition:

Angel YE, rich in protein, amino acids, peptides, nucleotides, B vitamins and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency and stable quality, Angel YE are widely applied in the biological laboratories and industrial-scale fermentation, promoting the product safety and technical progress in the global fermentation industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86-717-6369227

Fax: +86-717-6368757

email: aie@angelyeast.com