April 24, 2020

By Yinqiang

As we all know, proteins have complex structures and many types, so their hydrolysates have similar characteristics. Protein-containing raw materials are called organic nitrogen sources in biological culture. In fact, organic nitrogen sources not only provide nitrogen, but are also needed for biological growth and product secretion regulation, such as vitamins. In addition, the organic nitrogen source often contains a large amount of carbon source.

Because organic nitrogen source is the most important component of the culture medium, and its structure is complex and diverse, and its quality is difficult to control, when using organic nitrogen source, it is necessary to carefully analyze its raw material source, process, key indicators, etc. , even go to production site for inspection, otherwise, if there is a problem with the raw materials, for a complex fermentation system, it is easy to cause huge economic losses due to the reason that it cannot be quickly targeted. Therefore, stable quality is the basic guarantee for the long-term relationship between supply and demand.

This article provides a comprehensive overview of peptone from concepts, raw materials, classification, ingredients, processing methods, and analytical methods. It is an article worth collecting for a long time.

In addition, it is precisely because of the complex composition of peptone that it is possible to use peptone in the fermentation of each microorganism. Even if it is not for large-scale applications, it may also be used in research and development to obtain key influencing factors or precursors to create opportunities for greatly increasing production.

What is peptone?

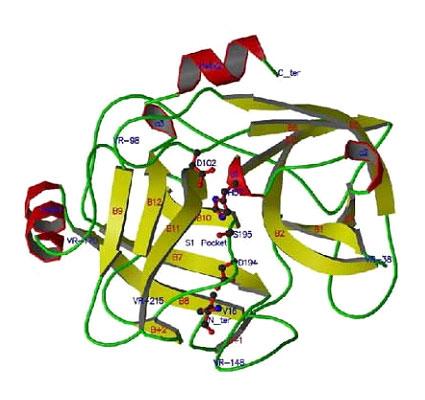

Peptone, a protein decomposition product, is made by incomplete hydrolysis process of the protein originated from beef, casein, milk powder, gelatin, soy protein, silk protein, fibrin, etc. The commercially available products are mainly light yellow to brown yellow powder. Its molecular weight is between proteose and peptide (about 2000Da).

The most critical term for this concept: one point is incomplete hydrolysis which is a non-quantitative term. Therefore, for each company, the types of enzymes used for protein decomposition and the degree of enzymolysis will be different, therefor, different peptones, for precisely controlled biological processes, are not universal and need to be tested to verify their usability. The catalytic effect of the enzyme itself is also not precise, and the hydrolysis activity of the enzyme will also be impacted by the enzyme itself and the catalytic environment.

Another key term of this concept is protein: different species, even different parts of the same species, have different types of proteins, so their products are also complex and changeable.

Main features: multiple influences, complex composition

Proteins can also form peptones after being hydrolyzed by acids, alkalis or proteases. Different sources of protein and different hydrolysis conditions would make the composition of hydrolysate vary widely, so peptone is often a complex mixture of peptides. In addition to amino acids, peptone also includes many other components, so it can provide carbon sources, nitrogen sources, growth factors and other nutrients for biological cultivation and fermentation.

In general, proteins used for peptone production include proteins of animal origin, plant origin, and microbial origin. At present, the research on artificial meat has become a hot spot. It is believed that by-products of artificial meat in the future may also become the source of peptone raw materials, which is beyond the scope of this article.

Animal protein mainly include: tryptone, meat peptone, bone peptone, silk pupae peptone, blood peptone, fish and shrimp powder, milk powder, etc.

Knowledge expansion: the main process of preparing peptone by using pig bone as raw material

1. Raw materials: mainly pig bones. Put the prepared raw materials in the pot, rinse with water at 40-50℃, then add water, the ratio is 1: 1.2.

2. High temperature extraction: heating and pressurizing to 4kgf / cm2, maintaining pressure balance for 2h.

3. Adjust pH: Take industrial hydrochloric acid to adjust the pH of the broth to 5.2.

4. Digestion: Reduce the temperature of the broth to a suitable temperature, and then add digestive enzymes for digestion.

5. Concentration: The digested broth is filtered with double gauze, and then the supernatant is heated and concentrated.

6. Drying: The concentrated thin paste is dried, then pulverized and packed separately.

Flow chart: fresh bone →crushing →cooking →debris removal, degreasing →enzymolysis →high temperature inactivation →filtration →spray drying →finished product →physical and chemical detection →bacterial culture.

Vegetable peptone

Peptone, produced from peanut meal and soybean, are vegetable peptones. Vegetable peptone has a relatively high sugar content.

Knowledge extension: Process of preparing peptone from defatted cold pressed peanut meal:

Accurately weigh 5g of defatted cold-pressed peanut meal and dissolve it in 250 mL of deionized water, adjust the pH to 2.0 with hydrochloric acid, add 5% pepsin (based on the substrate, 3 000 U / g) and stir at 37 ℃, do enzymatic hydrolysis for 200 min, regularly monitoring the degree of hydrolysis; After completion of the hydrolysis, adjust the pH of the hydrolysate to 8.0 with NaOH, add 2% alkaline protease (based on substrate, 50 000 U / g), enzymatic hydrolysis was carried out at 50 ℃for 190 min, and the DH%(Degree of hydrolysis) was monitored regularly; After the completion of the hydrolysis, the enzymolysis solution was placed in a boiling water bath for 10 min to kill the enzyme. After cooling to room temperature, centrifuge at 5,000 5 000×g for 25 min at 4 ° C, and the supernatant was freeze-dried, that is, cold-pressed peanut meal peptone.

Microbial peptone

For example, yeast peptone belongs to microbial peptone. Generally speaking, the microbial cell composition is simple and the protein content is high, so it is more suitable for large-scale application. The total nitrogen of bacterial peptone generally exceeds 14.5%.

Important indicators

Before using any kind of raw material, the standard of the raw material needs to be confirmed. This process needs to correlate the detected raw material standard with the use effect, and then select key impact indicators from it. If the key impact indicators cannot be established for the time being, the shake flask test can be used for raw material acceptance for the time being, but this standard is often difficult to be compatible with the standard provided by the raw material manufacturer.

Total nitrogen content

Peptone is mainly used as a nutrient substrate to provide nitrogen source in microbial growth or product synthesis. Therefore, nitrogen content is an important quality evaluation index of peptone. The total nitrogen of high-quality bacterial peptone is above 14.5%, and the vegetable peptone has a total sugar content of not less than 8.5% due to its relatively high sugar content. Total nitrogen is always measured by Kjeldahl method

Amino nitrogen content

The content of amino nitrogen can reflect the degree of protein hydrolysis, and analysis of the content of amino nitrogen is very important for judging the quality of peptone. There may be some differences in the colony size and growth morphology of the same microorganism on peptone medium with different amino nitrogen content. As a reagent grade peptone, its quality standards require that its amino nitrogen no less than 2.5%. Amino nitrogen content was determined by formaldehyde titration

Sugar content

The sugar content of vegetable peptone is usually higher than that of animal protein, and the sugar content of different animal peptones also varies. For example, the sugar content of casein peptone is (0.64 ± 0.22)%, chicken feather peptone is 0.76%, fish peptone is 1. 33%. Because vegetable peptone has a relatively high sugar content, it is not suitable for formulating sugar fermentation medium. Sugar content is measured by phenol sulfuric acid method.

Nitrite

Some microorganisms can reduce the pH of the culture medium during the growth and fermentation process, so that the amines generated by the decomposition of nitrite and protein generate nitrosamines. Therefore, peptone should not contain nitrite, otherwise, it may be impact safety.

The nitrite method uses aminobenzenesulfonic acid ⁃α⁃naphthylamine test solution for determination.

Phosphorus content

Phosphorus is an important nutrient matrix for microbial biosynthesis of biological macromolecules (such as nucleic acids and proteins), as well as an important pH buffer substance for the culture medium. Generally, the amount of phosphorus added in the medium is 0.005 ~ 0.010 mol / L. The excessively high phosphorus content is not good for the growth of microorganisms, and it is easy to cause eutrophication. Therefore, the phosphorus content in peptone should be controlled. Phosphorus content is determined by colorimetry (measurement wavelength 820 nm).

Sodium chloride content

Sodium chloride is the main salt from neutralization process of peptone. When the concentration of NaCl in the medium is too high, the osmotic pressure of the medium is usually also high, which is not conducive to the growth of microorganisms. Therefore, the NaCl content during the production of peptone should be controlled. Sodium chloride content is determined by titration

Ash

Peptone ash is mainly derived from raw materials and inorganic salt substances such as phosphate, silicate and sodium chloride used in the production process. The level of ash content has an important relationship with the production process and production raw materials. For example, when peptone is prepared by acid hydrolysis or alkaline hydrolysis, the ash content is usually relatively high, which can reach more than 20%. Under normal circumstances, when the ash content is too high, the peptone needs to be desalted to reduce the ash content. Enzyme hydrolysis can effectively solve the problem of too high ash content. Peptone as a biochemical reagent usually requires ash content no more than 15.0%. Ash content is measured according to GB 5009.4-2016

Moisture content

The moisture content of peptone for biochemical reagents should be less than 5%, and industrial-grade peptone does not have specific requirements for moisture content. When the moisture content of peptone is too high, it is easy to absorb moisture, connect to form a block, darken, deteriorate, and be susceptible to degradation. It is a key control indicator, which not only affects the appearance of the product, but also affects the growth of microorganisms and the synthesis of metabolites. In general, the water content of standard peptone is (3.83 ± 0.13)%. Moisture content is determined according to GB 5009.3-2016

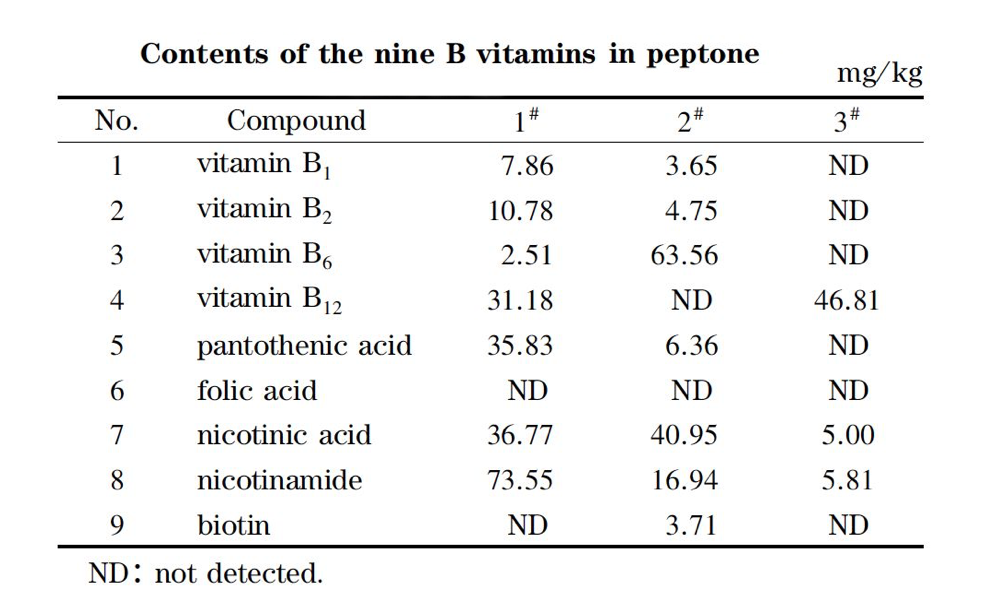

Vitamin content

Most fermentation engineers have realized that the quality of the medium and the quality of the batch are unstable. These differences between batches are often directly related to the differences between the batches of nitrogen sources. The direct enantiomeric relationship is that for fermentation, vitamins and free amino acids play a key role in the organic nitrogen source. At present, the world’s culture medium quality standard system is relatively backward, and there are few systematic researches on culture medium raw materials. The following table can directly reflect the huge difference in vitamin content in different peptones.

Free amino acid composition content

According to the definition of peptone, peptone is an incomplete hydrolysate of protein, so its composition is much more complicated than 20 amino acids. However, most of the organic nitrogen sources absorbed by microorganisms are free amino acids. Therefore, the ratio and type of free amino acids have become a key indicator of peptone and an important indicator of quality.

| Published by Yin Qiang Senior manager of Angel Yeast APAC Division |

About Angel Microbial Nutrition:

Angel YE, rich in protein, amino acids, peptides, nucleotides, B vitamins and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency and stable quality, Angel YE are widely applied in the biological laboratories and industrial-scale fermentation, promoting the product safety and technical progress in the global fermentation industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

ANGEL YEAST CO., LTD

Address: 168 Chengdong Avenue, Yichang, Hubei 443003, P. R.China

Tel: +86-717-6369227

Fax: +86-717-6368757

email: aie@angelyeast.com