-

Home > News & Events > Blog > Yeast & Baking

I. Analysis of current markets

laminated bread, such as croissants and medialunas, is popular for its crisp but soft mouthfeel, aromatic flavour and rich nutrition. However, its making requires complicated processes and high techniques. The criteria for evaluating the quality of such products are described as follows:

1. Volume and appearance: well-stacked, the bread shall have 5 cm3/g or higher specific volume; the bread crust shall be golden brown, bright, smooth and free of black bulges or apparent overbaking-caused spots.

2. Internal structure: elastic, multiporous, with clear textures but no cracks, distinct in texture layers, and even in structure.

3. Taste and mouthfeel: with crisp crusts and soft internal texture; savoury and free of unpleasant odor.

There are two main processes for making such type of products, traditional process and frozen dough process. The characteristics, merits and demerits are described below.

Process | Mode characteristics | Merit | Demerit |

Traditional process | Bread is produced at site in the places such as factories and bread stores. The process refers to the whole steps of mixing dough, adding oil, puffing up, forming doughs, fermentation and final baking. | The process can be finished once at a time, and the product has high, reliable quality. | The devices used for dough mixing, dough recovery, baking and other steps have to be arranged at the production site, resulting in long production time, high-level technical difficulties and high production costs. Besides, the consumption of fresh products cannot be achieved. |

Frozen dough process | The production links, such as the links in bread factories, only produce doughs. The doughs are frozen when they are totally unfermented or frozen immediately after partial fermentation. The frozen doughs are transferred to the end consuming places. The doughs to be used will be unfrozen and recovered before baking, or directly baked without recovery. Then the finished bread will be sold. | The links in factories can reduce equipment costs, minimize manpower, shorten production time and upgrade efficiency. The time-saving production at the consuming places contributes to flexible customer-oriented service, basically realizing the consumption of fresh products. | Both the dough freezing added to the production and the link of refrigeration transportation increase costs, and the investment of equipment and manpower is required in the end consuming places. The refrigeration transportation and storage of doughs will cause adverse effects on product quality. |

II. Angel A-Plus Croissant bread improver is developed to solve the problems in the traditional process and frozen dough process for making puff bread. It can improve product quality and stabilize frozen dough quality. The main functions of the improver are described below.

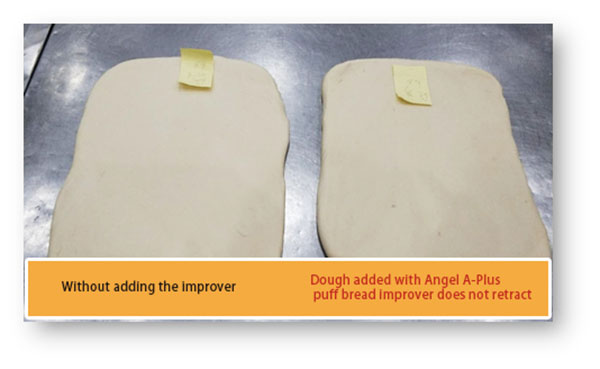

1. It can enhance dough extensibility. By using it, a stretched dough will not retract easily, and puffing will be effective.

2. The products are well stacked in appearance and large in size. The dough added with the improver can be over 20% larger. Additionally, doughs have even internal structures and clear texture layers.

3. The improver, applicable for the frozen dough process for croissant bread making, can enhance the stability of frozen doughs and prolong the storage term of frozen doughs.

The improver, which is applicable for making different types of croissant bread, can improve the dough adaptability in mechanical operation and enhance the fermentation stability of doughs. By using it, well-stacked break is obtainable. It can also be used in the frozen dough process for puff bread. It does not only enhance the stability of doughs during freezing and storage but also increases the bread size after unfreezing. Furthermore, the coloring effects on the bread products can also be improved.

| Published by Modern Xu Senior Engineer of Angel Baking Center |

About Yeast & Baking

Angel Yeast has absorbed the essence of the global baking industry to build a baking service platform and to provide more comprehensive solutions for the baking industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 150 countries and regions.

Press contact:

Angel Yeast Co., Ltd.

Address: 168 Chengdong Avenue, Yichang, Hubei, P. R. China

Tel: +86-717-6369520

Fax: +86-717-6370680

Email: aie@angelyeast.com