Non-alcoholic beer (NAB), defined as beer with an alcohol content of 0.5% or less by volume (GB/T 4927—2008 "Beer"), is a new type of beer. In today's trend toward healthy lifestyles, the non-alcoholic beer market is expanding at an astonishing rate. According to the latest market research data, the global non-alcoholic beer market size exceeded 20 billion US dollars in 2023, with an expected annual growth rate of over 15% in the next five years. However, traditional non-alcoholic beer production processes often face the dilemma of being "watery" or having "excessive alcohol residue." How can one meet the low alcohol standard of below 0.5% ABV while retaining the rich malt aroma and floral-fruity flavors of beer? Angel NA05—this niche yet powerful "soul yeast"—is emerging as brewers' new secret weapon. NA05 (Torulaspora delbrueckii) is a maltose-negative yeast. Its ability to serve as the "soul yeast" for non-alcoholic beer production stems from its innate unique capability:

1. Natural "low alcohol metabolism" gene

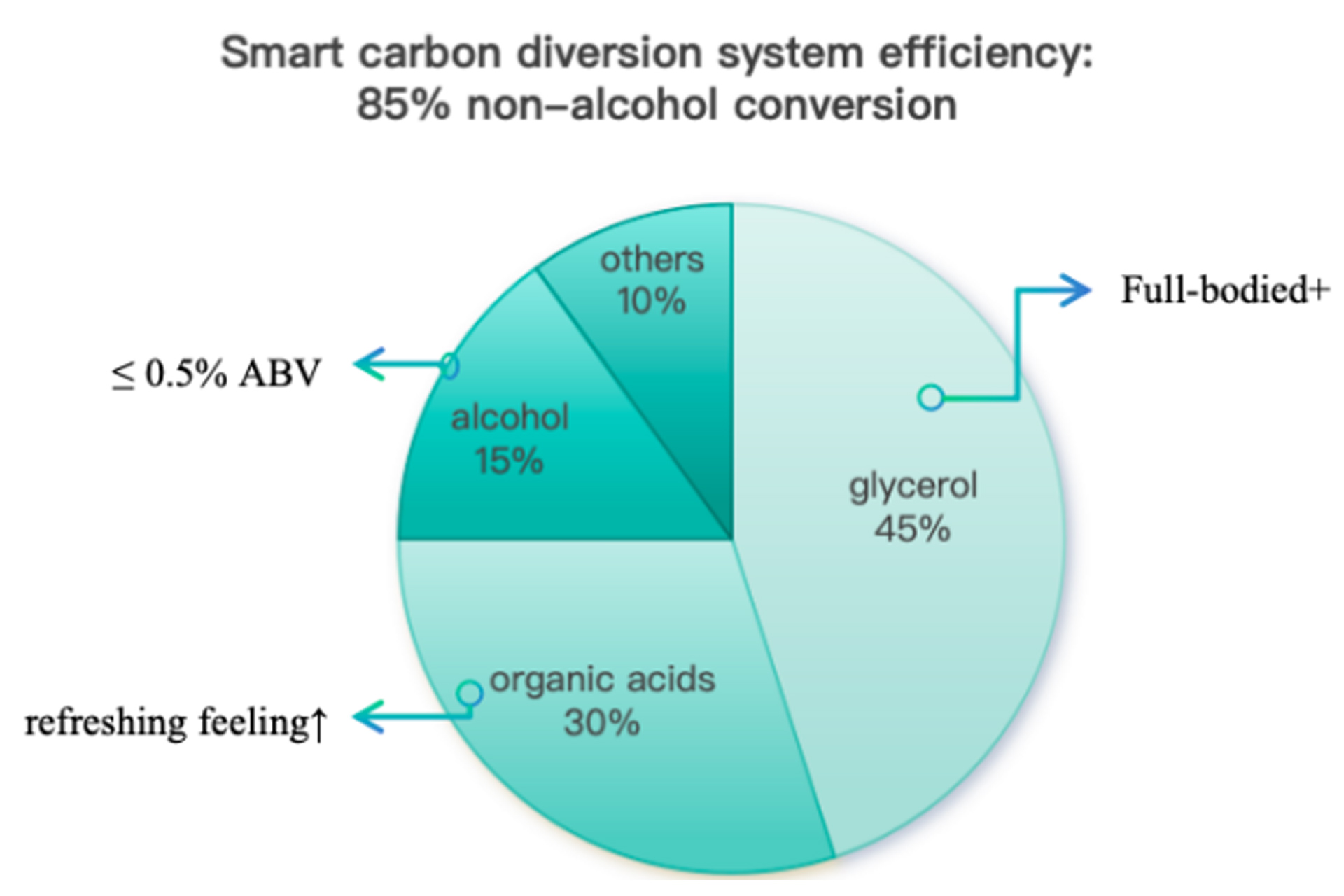

Compared to Saccharomyces cerevisiae, NA05 yeast has a sophisticated metabolic control network that directs more than 85% of fermentable sugars to non-alcoholic pathways. Approximately 45% is converted into glycerol, giving the wine a full-bodied taste; 30% is converted into organic acids, providing a refreshing taste experience; and less than 15% is ultimately converted into alcohol. This unique metabolic characteristic makes it an ideal choice for brewing low-alcohol beer.

Fig. 1 Carbon diversion metabolism diagram

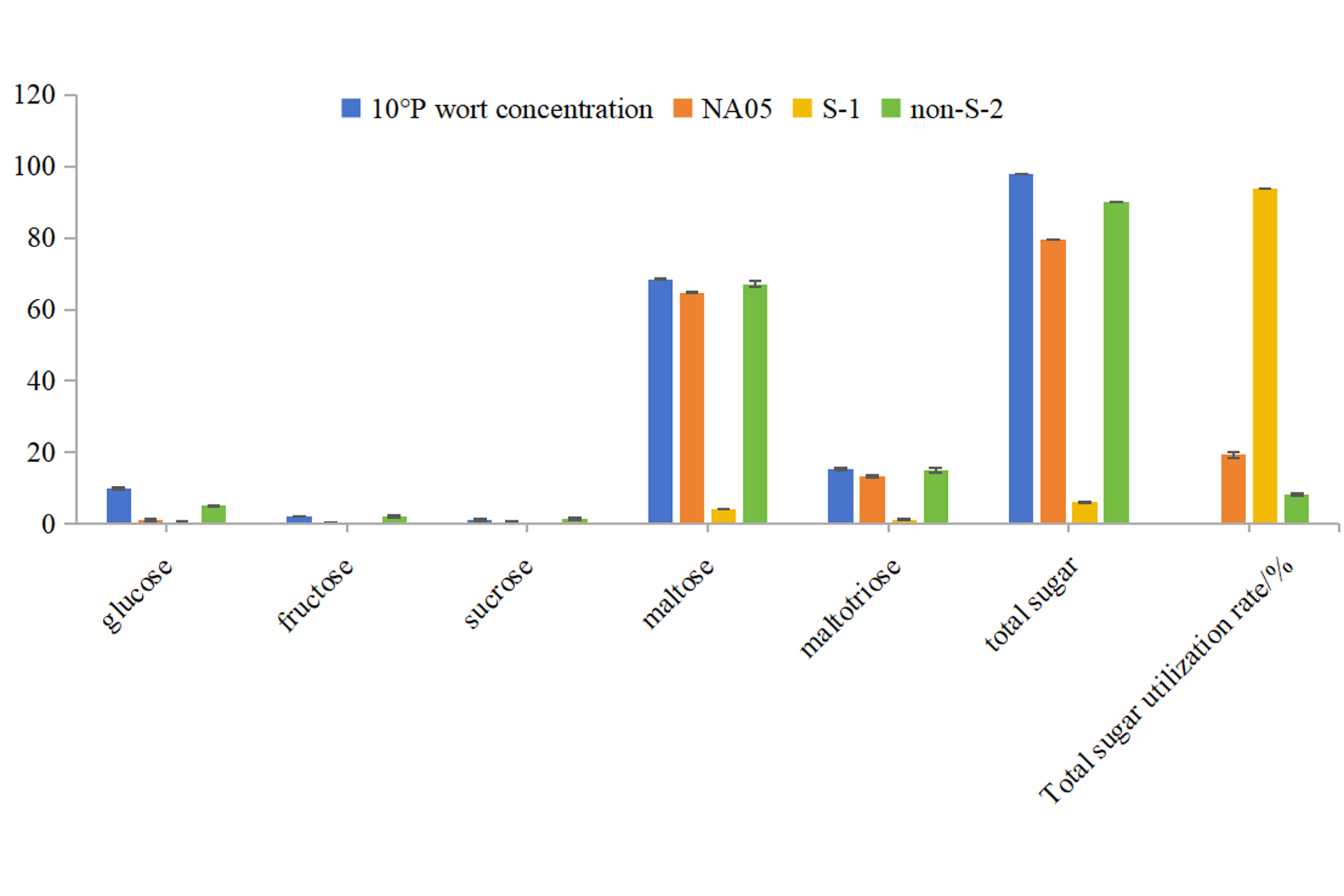

In the residual sugar determination shown in Figure 2, the sugar utilization rate of the S. cerevisiae S-1 reached 93.74%, while that of the NA05 strain was 19.4%, and the non-S. cerevisiae non-S-2 only achieved 8.24%. The non-S-2 strain had excess residual sugar content in the wort, resulting in overly sweet beer flavor and fewer flavor compounds. Compared to non-S-2, the NA05 strain utilized more sugar, including a small amount of maltose, with a total sugar utilization rate that increased by 132%, thereby imparting more favorable flavors to the beer.

Fig. 2 Residual sugar components from different yeast wort fermentations

2. Flavor guardian in low temperatures

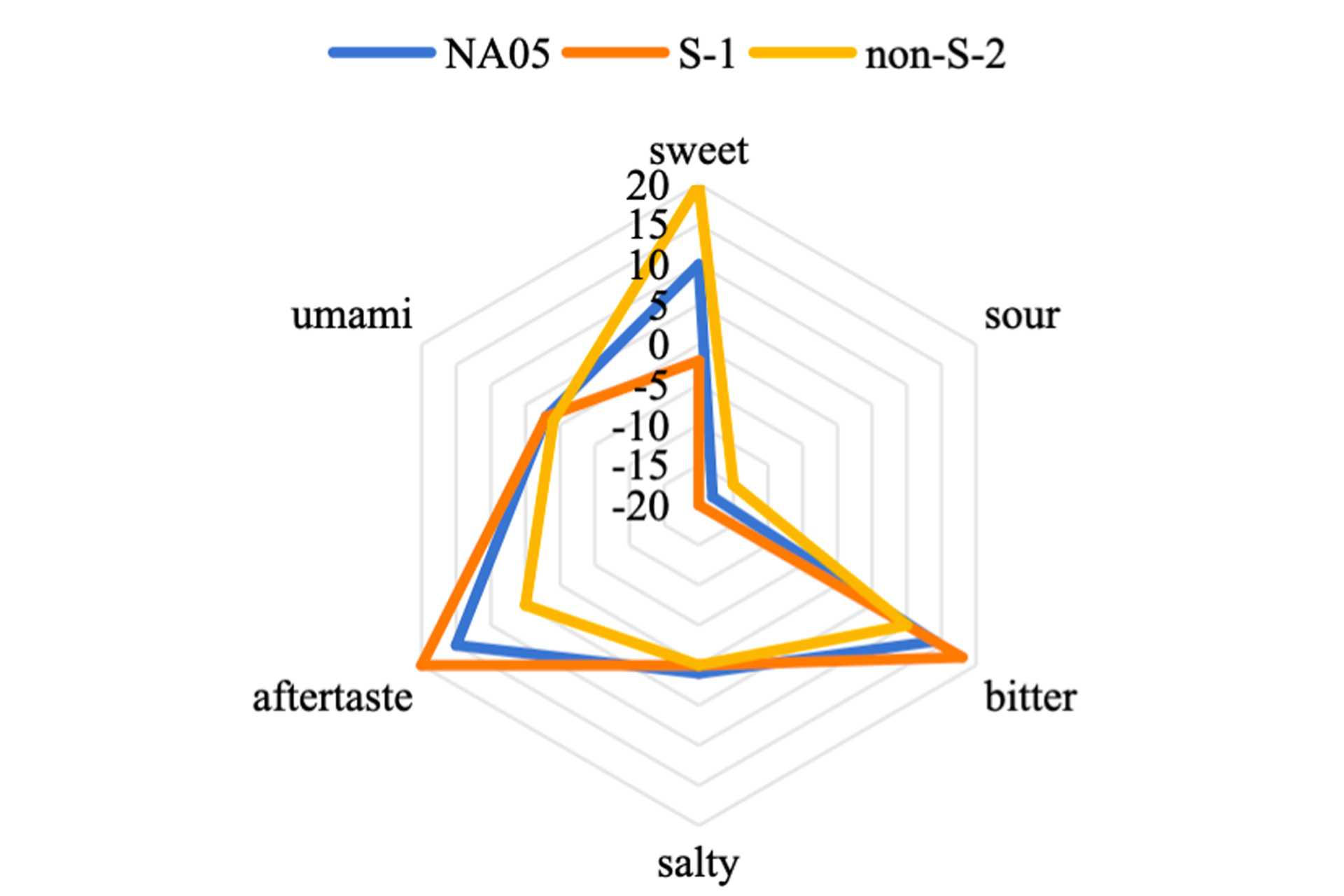

At low temperatures between 12 to 25°C, the flavor radar chart shows that the flavor of NA05-brewed non-alcoholic beer is concentrated in the aftertaste and bitterness, with a significant improvement in sweetness compared to non-S-2, thus avoiding a cloying sweet taste. NA05's ester synthase (AATase) maintains high activity even in low-alcohol environments, producing esters such as isovaleric acid isopentyl ester (citrus aroma) and ethyl acetate (red apple aroma), which are key sources of the beer's fruity aroma. Finally, the fermentation cycle for NA05 typically lasts 72~96 hours, a duration that ensures sufficient accumulation of flavor compounds while avoiding over-fermentation that could lead to excessive alcohol content. NA05 contributes neutral sensory characteristics to beer, making it the optimal choice for brewing non-alcoholic IPA and Pale Ale beers.

Fig. 3 Radar chart of different yeast fermentation flavors

| Published by Xiao Ke Engineer, Center for Industrial Microbiology and Brewing Technology |

About Angel Brewing

Angel Brewing focus on the brewing microbial resource industrialization and its industrialized application including global distilling spirit, wine, fermented condiment and global biofuel. The team of angel brewing experts provides brewing microbial products and fermentation solutions to global customers.

About Angel

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 170 countries and regions.

Press Contact

Tel.: +86 717 6353619

Email: niangzao@angelyeast.com