With growing global demand for sustainable development and clean labeling, the application of traditional animal-derived peptones in industrial fermentation faces multiple challenges, including supply chain instability, batch-to-batch variability, and limited access to specific markets. This study systematically evaluates the feasibility of substituting conventional bovine bone peptone (FP328) and pancreatic digest of casein (FP316) with Angel's animal-free composite peptones FP528 and FP516, respectively, aiming to provide the industry with reliable, compliant, and performance-stable alternative solutions.

1. Introduction

In current industrial fermentation systems, animal-derived peptones are widely used due to their excellent nutritional support. However, such raw materials often face issues such as unstable supply chains, significant compositional variations between batches, and difficulties in meeting specific market regulations such as vegetarian, halal, and kosher certifications. Additionally, fermentation companies face continuous cost pressures due to price fluctuations of animal by-products. Therefore, developing animal-free peptones with stable performance, sustainable sources, and compliance with diverse market requirements has become an important industry direction.

2. Materials and Methods

2.1 Test Samples

Four peptones were selected as test subjects in this study:

FP328 (Bovine bone peptone, animal-derived control): Prepared by enzymatic hydrolysis of bovine bone collagen.

FP316 (Pancreatic digest of casein, animal-derived control): Prepared by enzymatic hydrolysis of casein.

FP528 (Animal-free composite peptone): A blend of plant peptone and yeast peptone, with amino acid composition similar to FP328.

FP516 (Animal-free composite peptone): A blend of plant peptone and yeast peptone, rich in small peptides and trace elements.

2.2 Test Strains

Six Bacillus species commonly used in industrial fermentation were selected as test subjects: Bacillus subtilis, Bacillus velezensis, Bacillus licheniformis, Bacillus thuringiensis, Bacillus megaterium, and Bacillus amyloliquefaciens.

2.3 Experimental Methods

A Bioscreen automatic growth curve analyzer was used for cultivation monitoring. Under identical culture conditions, each of the four peptones mentioned above served as the sole nitrogen source. Equal amounts of bacterial inoculum were added, and cell growth density was monitored in real-time to plot growth curves and compare final biomass

3. Results

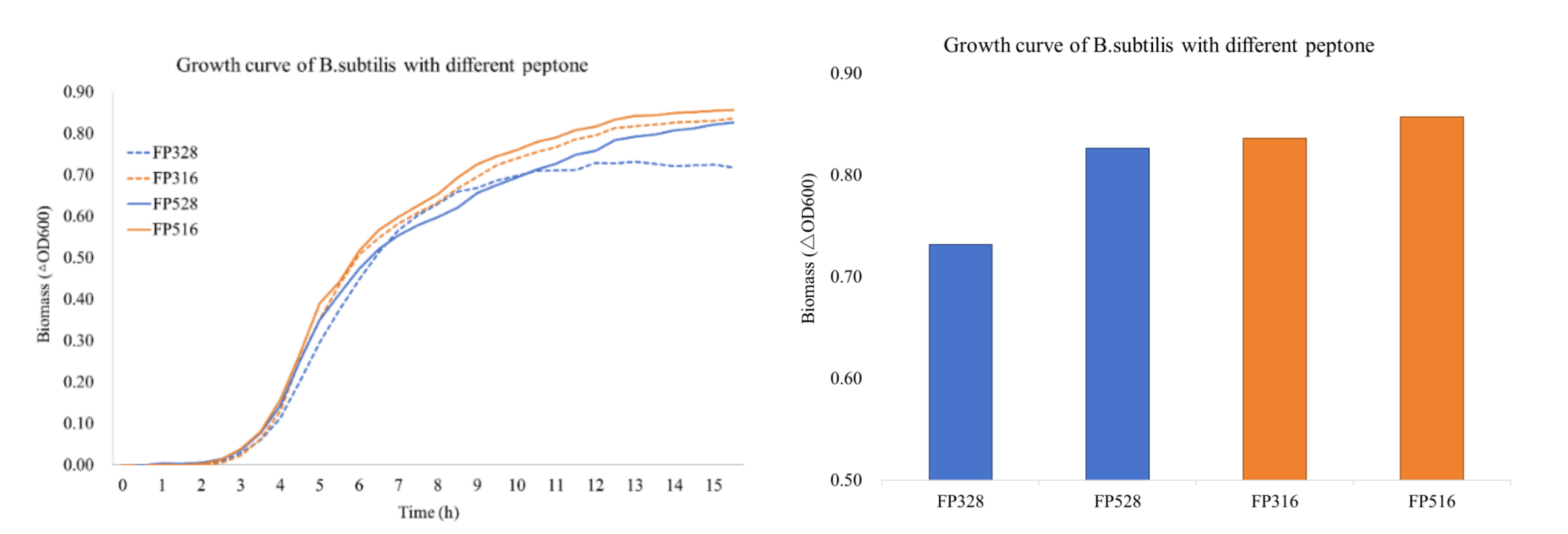

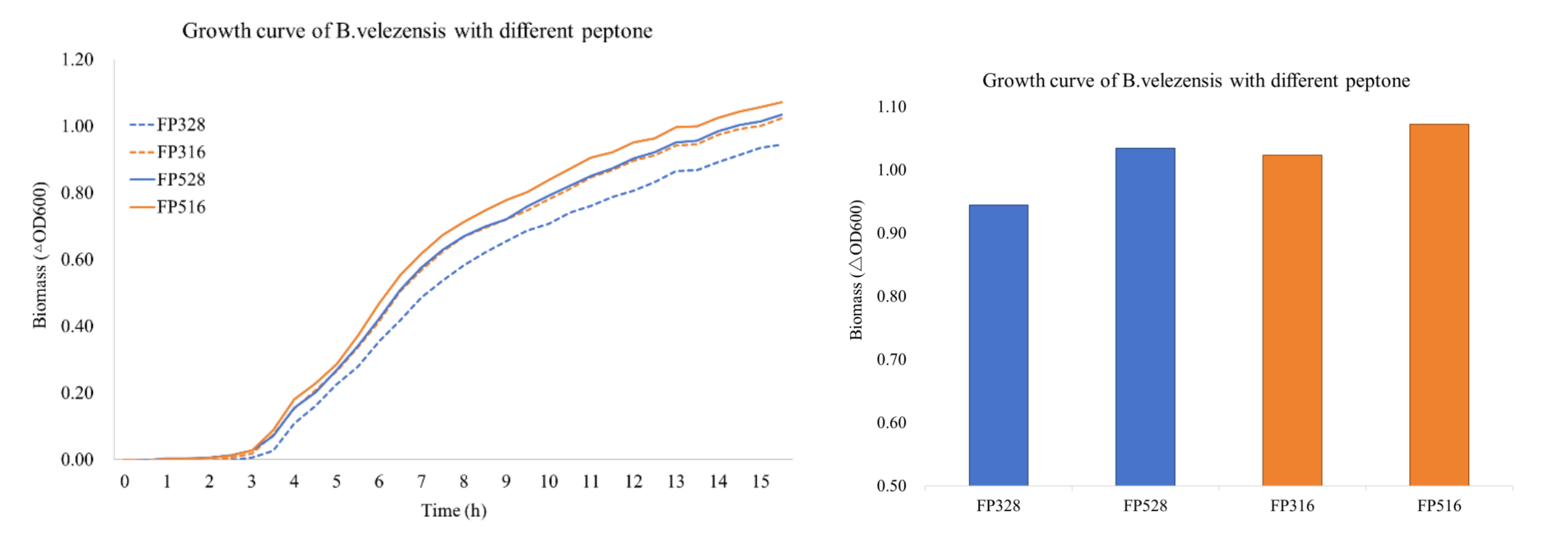

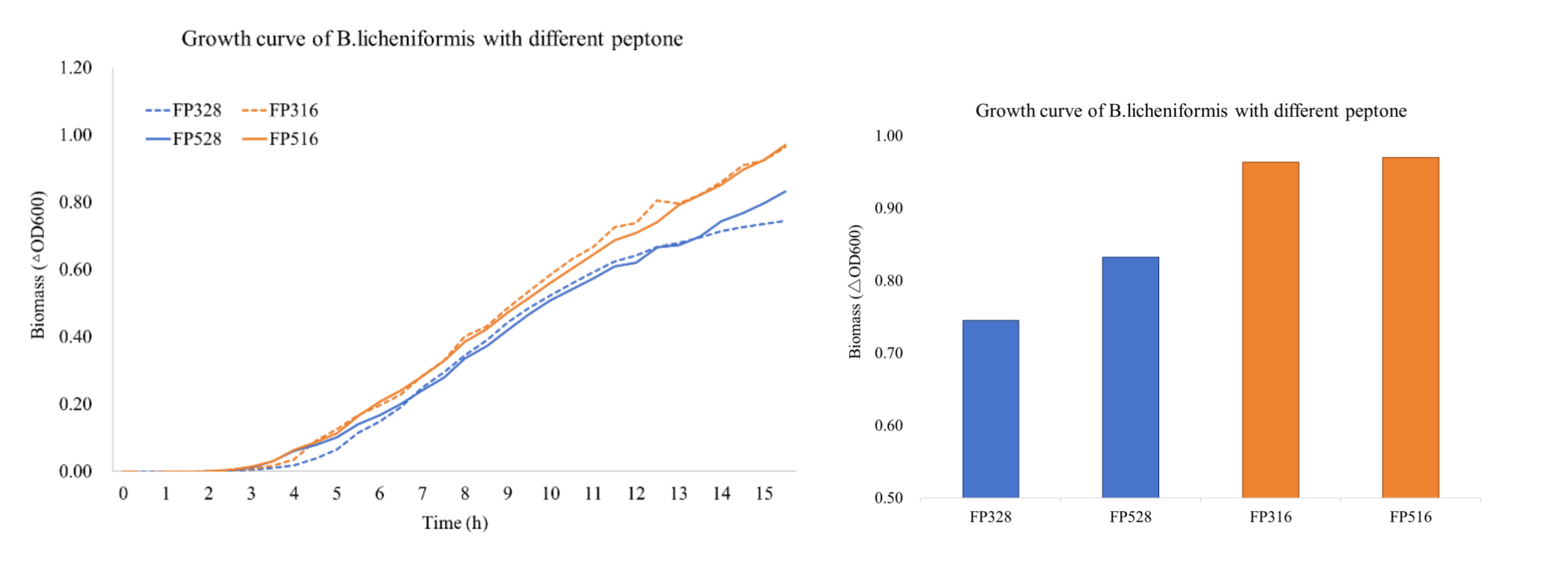

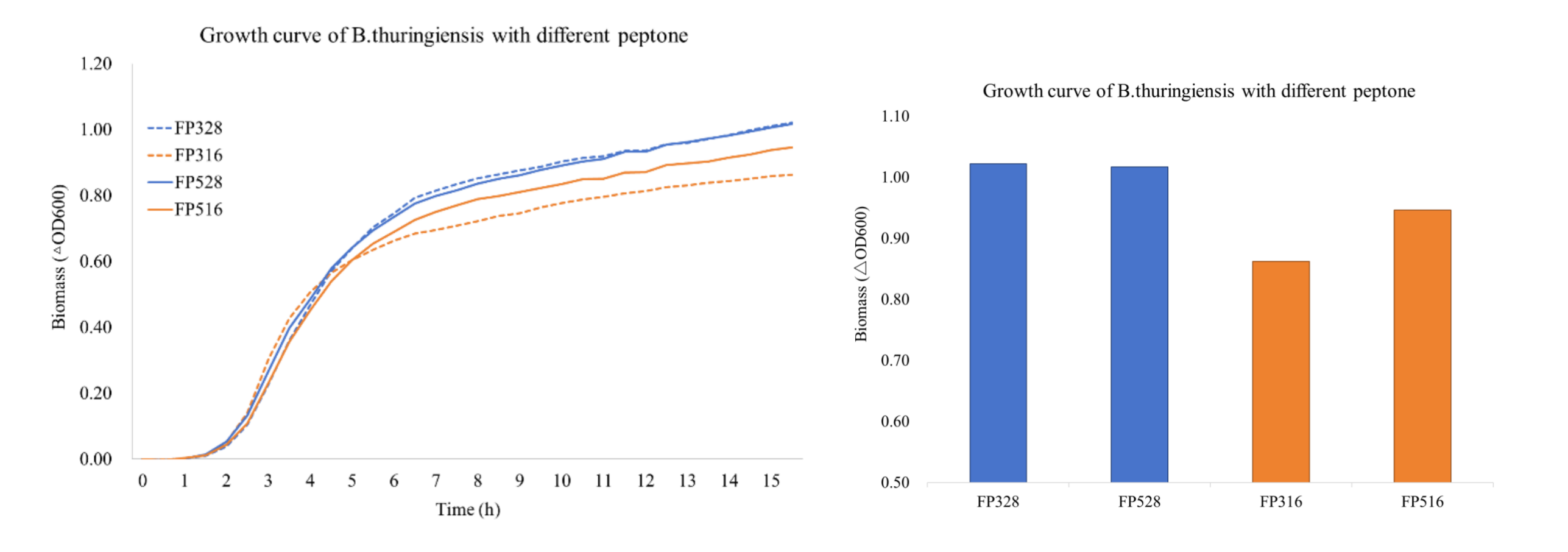

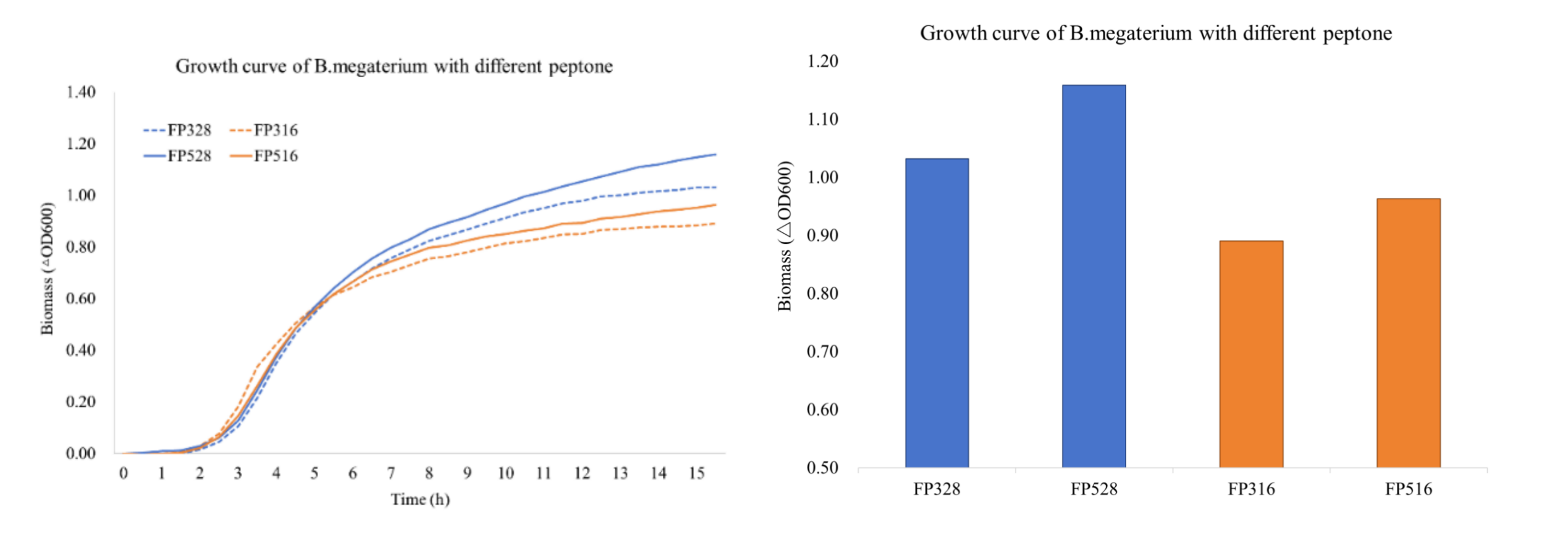

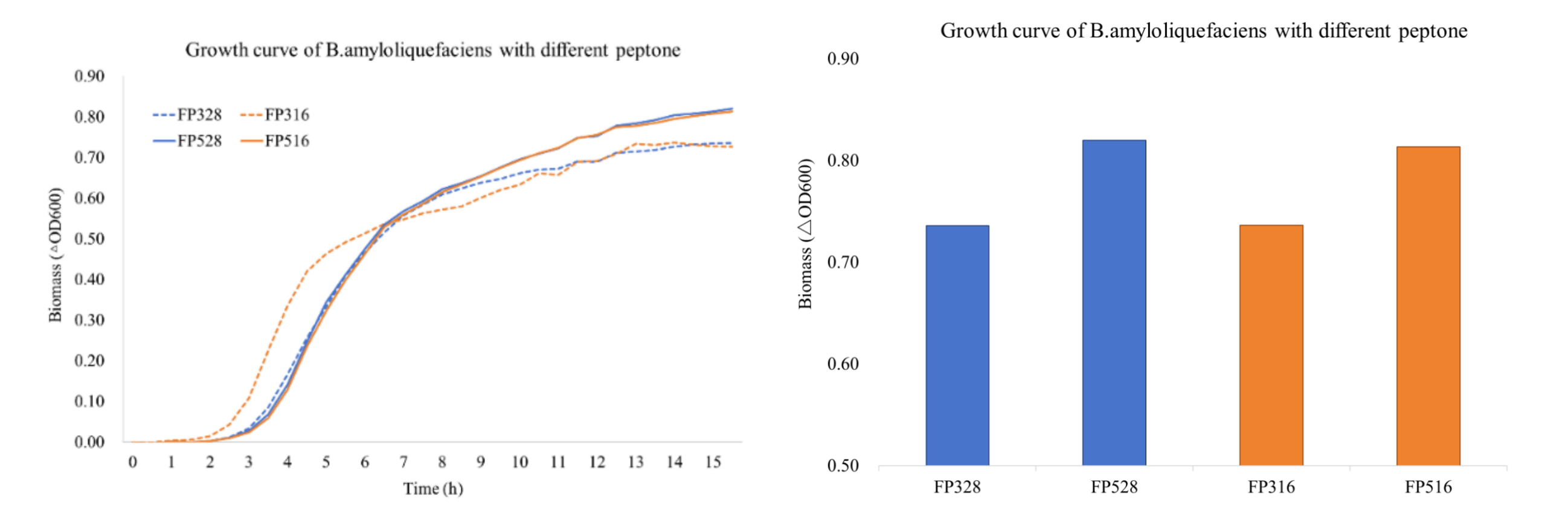

The growth curve determination results for the six Bacillus species are shown below. In each set of figures, the left side shows the growth curve of the animal-derived peptone (FP328 or FP316), and the right side shows the growth curve of the animal-free substitute (FP528 or FP516). All data were measured using the Bioscreen automatic growth curve analyzer.

1. Growth Comparison of Bacillus subtilis

2. Growth Comparison of Bacillus velezensis

3. Growth Comparison of Bacillus licheniformis

4. Growth Comparison of Bacillus thuringiensis

5. Growth Comparison of Bacillus megaterium

6. Growth Comparison of Bacillus amyloliquefaciens

*Note: The illustrated growth curves indicate that FP528 and FP516 show growth trends similar to or better than their corresponding animal-derived peptones in each bacterial species, with comparable or higher biomass during the stationary phase.

4. Analysis and Discussion

Based on the above growth curve comparisons, the following conclusions can be drawn:

Consistency in Growth Trends: The growth curve patterns of FP528 and FP516 in the six Bacillus species closely match those of FP328 and FP316, respectively, indicating that they can provide continuous and stable nutritional support during fermentation.

Biomass Performance: In most tested strains, the final biomass of the animal-free peptone groups reached or slightly exceeded that of the animal-derived control groups, demonstrating their potential in cell synthesis.

Substitution Feasibility: From the perspective of growth kinetics, FP528 and FP516 possess the technical foundation for direct substitution of corresponding animal-derived peptones.

4.1 Technical Feasibility

From the perspectives of amino acid composition, small peptide content, and trace elements, FP528 and FP516 achieve a nutritional structure similar to animal-derived products through scientific raw material formulation. Experimental data show that they can provide stable and efficient growth support in multiple Bacillus species, validating their usability in actual fermentation processes.

4.2 Production and Market Advantages

High Batch Stability: Plant and yeast raw materials are controllable in source, and precise production processes effectively reduce fermentation inconsistency caused by raw material fluctuations.

Compliance and Sustainability: Products are entirely developed from plant and yeast sources, naturally complying with vegetarian, halal, kosher, and other certification systems, while reducing dependence on animal by-products and supporting corporate sustainability goals.

Supply Chain Resilience: Raw materials are not restricted by animal epidemics or international trade policies, ensuring more stable and reliable supply.

Cost Controllability: Avoiding the impact of sharp price fluctuations in animal-derived raw materials helps companies achieve long-term cost optimization.

4.3 Application Recommendations

It is recommended to conduct pilot-scale verification during the substitution process and fine-tune parameters according to specific bacterial strains and process conditions. Angel can provide corresponding technical support to assist companies in achieving a smooth transition and process optimization.

5. Conclusion

This study confirms through systematic experiments that animal-free composite peptones FP528 and FP516 can effectively substitute traditional bovine bone peptone and pancreatic digest of casein in various Bacillus fermentations. They not only perform comparably or better in growth performance but also offer superior batch stability, market compliance, and supply chain security. This substitution strategy provides the fermentation industry with a reliable, sustainable, and cost-effective technological pathway suitable for global promotion under clean labeling and sustainable development trends.

About Angel Fermentation Nutrients:

Angel Fermentation Nutrients, rich in protein, amino acids, peptides, nucleotides, B vitamins, and trace elements. With the advantages of having no allergic source and being non-transgenic, high efficiency, and stable quality, Angel YE are widely applied in biological laboratories and industrial-scale fermentation, promoting product safety and technical progress in the global fermentation industry.

About Angel:

Angel Yeast Company is a high-tech listed company specializing in yeast and biotech. Product business covers Yeast and Baking, Yeast Extract-Savoury, Nutrition & Health and Biotechnology fields. It is one of the world's leading companies in the yeast industry. Angel has 12 holding subsidiaries and provides products and services for more than 160 countries and regions.

Press contact:

email: yef@angelyeast.com